Filter by

Width

DFARS Specialty Metals

Throat Depth

Export Control Classification Number (ECCN)

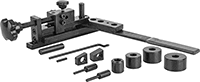

Adjustable-Width Sheet Metal Benders for Bench Vises

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Bending Wd. | For Max. Steel Thk. | For Jaw Wd. | Ht. | Wd. | Dp. | Max. Box Dp. | Frame Material | Ht. | Wd. | Dp. | Handle Grip Material | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 1/2" | 1/16" | 4" to 8" | 11" | 13" | 2" | 1" | Steel | 1" | 9 1/2" | 1/2" | Rubber | One 1" Wide Forming Die One 2 7/8" Wide Forming Die One 2" Wide Forming Die One 5 7/8" Wide Forming Die | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Sheet Benders

Sheet Benders | V-Groove Attachments | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Electrical | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Bending Wd. | For Max. Sheet Thk. | Ht. | Wd. | Dp. | Max. Temp., ° F | Connection | No. of Blades | Voltage, V AC | Cord Lg., ft. | Features | Certification | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Frame | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/2" | 1 1/4" | 35" | 4" | 800 | Straight Blade | 3 | 120 | 5 | — | — | 00000000 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 1/2" | 1 1/4" | 59" | 4" | 800 | Straight Blade | 3 | 120 | 5 | — | — | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 1/2" | 5" | 53" | 7" | 450 | Straight Blade | 3 | 120 | 7 1/2 | On/Off Switch, Pilot Light, Thermostat Control | CSA Certified | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 72" | 1/2" | 1 1/4" | 83" | 4" | 800 | Straight Blade | 3 | 120 | 5 | — | — | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" | 1/2" | 1 1/4" | 107" | 4" | 800 | Straight Blade | 3 | 120 | 5 | — | — | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Frame | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 1/2" | 4" | 64" | 2" | 400 | Straight Blade | 3 | 120 | 6 | On/Off Switch, Thermostat Control | — | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" | 1/2" | 4" | 114" | 2" | 400 | Straight Blade | 3 | 120 | 6 | On/Off Switch, Thermostat Control | — | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Economy Sheet Metal Benders

Sheet Metal Benders

Sheet Metal Benders | Floor Stands | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Bending | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wd. | Angle | For Max. Steel Thk. | Ht. | Wd. | Dp. | Clearance | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 135° | 3/64" | 9" | 32" | 15" | 4" | Steel | No | 3 | 3/8" | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37" | 135° | 3/64" | 9" | 45" | 15" | 4" | Steel | No | 3 | 3/8" | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hand-Held Sheet Metal Benders for Long Folds

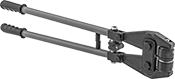

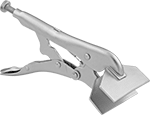

Strong-Grip Sheet Metal Bender/Crimpers

|

Throat Dp. | Jaw Wd. | Lg. | Material | Each | ||

|---|---|---|---|---|---|---|

| 1 3/4" | 3 1/8" | 8" | Steel | 0000000 | 000000 |

Hand-Held Sheet Metal Benders for Making Corners

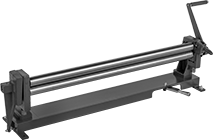

Slip Rollers

Roller | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Bending Wd. | For Max. Steel Thk. | Min. Bending Radius | For Wire Dia. | Ht. | Wd. | Dp. | Material | Dia. | No. of | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" | 1/2" | 1/16", 1/8" | 8" | 17" | 12" | Steel | 1" | 3 | Cast Iron | No | 4 | 3/8" | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 38" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 51" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 1/64" | 1" | 3/16", 1/4", 5/16" | 19" | 57" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sheet Metal Shrinker/Stretchers

Portable

Throat Dp. | Jaw Wd. | For Max. Steel Thk. | Material | Lg. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 1 9/16" | 1/16" | Steel | 27" | Hex Key, Pair of Shrinking Jaws, Pair of Stretching Jaws, Three Shims, Wrench | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

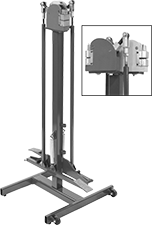

Stand Mount

Stand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Throat Dp. | Jaw Wd. | For Max. Steel Thk. | Material | Ht. | Wd. | Dp. | Ht. | Wd. | Dp. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 3/4" | 3/64" | Steel | 5 1/2" | 1 3/4" | 4 1/2" | 42" | 20" | 22" | Two Foot Pedals, Two Rigid Casters | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Benders

For Max. Flat Stock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Die Dia. | For Max. Wire Dia. | Thk. | Wd. | For Max. Rod Dia. | Material | Lg. | Wd. | Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4", 1 1/4", 1 5/8" | 1/2" | 1/4" | 1" | 1/2" | Steel | 20" | 2" | 5" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Floor-Mount Adjustable-Width Sheet Metal Benders

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Bending Wd. | For Max. Steel Thk. | Min. Reverse Bend | Ht. | Wd. | Dp. | Max. Box Dp. | Frame Material | Mounting Fasteners Included | No. of | Dia. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 1/4" | 1/16" | 1/4" | 53" | 72" | 36" | 4" | Steel | No | 4 | 5/8" | Five 2" Wide Forming Dies Six 3" Wide Forming Dies Five 4" Wide Forming Dies Removable Apron Insert Apron Stop Rod Counterweights | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Force Duct Crimpers

|

Throat Dp. | Notch Increments | Jaw Wd. | Lg. | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 1 1/4" | 1/4", 1/2", 3/4", 1", 1 1/4" | 7/8" | 9 3/4" | Steel | 0000000 | 000000 |

Seam-Opening Pliers

|  |

Jaw Wd. | Lg. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 10" | Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

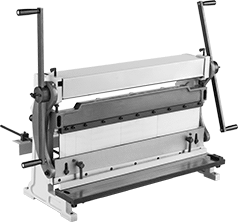

Shears/Benders/Curvers

Max. Bending | For Max. Thk. | Roller | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Angle | Aluminum | Brass | Copper | Stainless Steel | Steel | Min. Bending Radius | Cut Lg. | Ht. | Wd. | Dp. | Dia. | No. of | Blade Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 90° | 1/32" | 1/32" | 1/32" | 1/64" | 1/32" | 3/4" | 12" | 15" | 14" | 11" | 1 1/2" | 3 | Steel | No | 4 | 0.32" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 90° | 3/64" | 1/32" | 1/32" | 1/64" | 1/32" | 3/4" | 30" | 23" | 32 1/2" | 14 1/2" | 1 1/2" | 3 | Steel | No | 4 | 0.32" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40" | 90° | 3/64" | 1/32" | 1/32" | 1/64" | 1/32" | 7/8" | 40" | 23" | 42 1/2" | 14 1/2" | 1 5/8" | 3 | Steel | No | 4 | 0.32" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

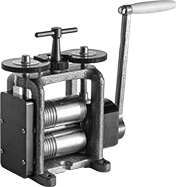

Benchtop Rolling Mills

Manual

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Square Wire Size | Half-Round Wire Size | Gear Speed Ratio | Ht. | Wd. | Dp. | Handle Lg. | Dia. | No. of | Material | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 9/16" | 3/16" | 3/64", 5/64", 1/8", 5/32", 3/16", 13/64", 7/32", 15/64", 1/4" | 0.098", 0.118", 0.157" | 4:1 | 14" | 12" | 8" | 12" | 2 1/2" | 2 | Steel | Cast Iron | No | 6 | 3/8" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

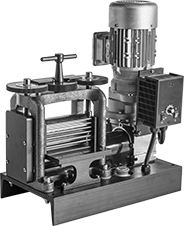

Electric

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Gear Speed Ratio | Ht. | Wd. | Dp. | Dia. | No. of | Material | Frame Material | Power, hp | Max. Rotation Speed, rpm | Current, amp | Voltage, V AC | Cord Lg., ft. | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | 3/16" | 100:1 | 19" | 22" | 15" | 2 1/2" | 2 | Steel | Cast Iron | 1/2 | 13 | 1.7 | 120 | 5 | No | 4 | 1/2" | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

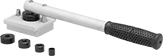

Economy Benders

Wire, Rod, and Flat Stock Curvers

|  |

Curver | Curver with Stand |

For Max. Flat Stock | Stand | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Dia. | Thk. | Wd. | For Rod Dia. | Min. Bending Radius | Material | Ht. | Wd. | Dp. | Handle Lg. | Roller Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/16" | 1" | 1/4" | 1 1/2" | Steel | 5 1/2" | 6 1/2" | 5 1/2" | 13 1/2" | 1 1/4" | — | — | — | No | 2 | 3/8" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4", 1/2" | 3/16" | 1" | 1/4", 1/2" | 1 3/8" | Steel | 6 3/4" | 5 1/2" | 9 3/4" | 9" | 1 13/16" | 39" | 21" | 21" | Yes | 2 | 5/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Depth-Measuring Sheet Metal Bender/Crimpers

|

Throat Dp. | Notch Increments | Jaw Wd. | Lg. | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 1 1/4" | 1/4", 1/2", 3/4", 1", 1 1/4" | 3 1/4" | 8" | Steel | 0000000 | 0000000 |

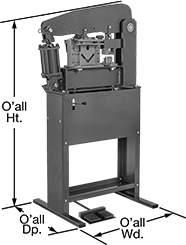

Floor-Mount Presses/Punches/Shears

Overall | Electrical | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Throat Dp. | Ht. | Wd. | Dp. | Steel Thk. for Pressing | Steel Rod Dia. for Shearing | Sheet Metal Size for Shearing, Thick. × Wd. | Power, hp | Voltage, V AC | Connection | No. of Blades | Cord Lg., ft. | Each | ||

| 80,000 | 3 3/4" | 55 1/4" | 30" | 24" | 3/8" | 3/4" | 3/8" × 4", 1/4" × 6" | 1 1/2 | 120 | Straight Blade | 3 | 5 | 00000000 | 000000000 | |

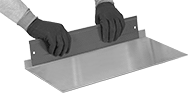

Hand-Held Sheet Metal Benders for Large Sheets

Throat Dp. | Jaw Wd. | Max. Bending Angle | For Max. Steel Thk. | Lg. | Ht. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" to 19 5/8" | 19 5/8" | 150° | 1/64" | 31 1/2" | 4 1/4" | Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

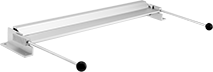

Bench-Top Adjustable-Width Sheet Metal Benders

Sheet Metal Benders | 26" Ht. Floor Stand | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Bending Wd. | For Max. Steel Thk. | Min. Reverse Bend | Ht. | Wd. | Dp. | Max. Box Dp. | Frame Material | Mounting Fasteners Included | No. of | Dia. | Handle Grip Material | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 1/4" | 3/64" | 1/4" | 25" | 65" | 22" | 4" | Steel | No | 4 | 1/2" | Plastic | Five 2" Wide Forming Dies Six 3" Wide Forming Dies Five 4" Wide Forming Dies Removable Apron Insert Apron Stop Rod Counterweights | 0000000 | 000000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Depth-Measuring Sheet Metal Bender/Crimpers for Tight Spaces

|

Throat Dp. | Notch Increments | Jaw Wd. | Lg. | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 1 1/4" | 1/4", 1/2", 3/4", 1", 1 1/4" | 3 1/4" | 9" | Steel | 0000000 | 000000 |

Handheld Bead Rollers

Throat Dp. | For Max. Steel Thk. | Max. Bending Angle | Graduations | Numeric Graduations | Lg. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" to 8" | 1/32" | 90° | 1/8" | 1" | 13 1/2" | Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sheet Metal Bead Rollers

Roller | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Throat Dp. | Ht. | Wd. | Dp. | For Max. Steel Thk. | Mount Type | Max. Mounting Surface Thk. | Material | Ctr.-to-Ctr. | Material | Includes | Each | |||

| 7" | 35" | 15 3/8" | 21 1/8" | 1/64" | C-Clamp | 2 3/4" | Steel | 2" | Iron | Rollers for Burring, Crimping, Wiring, 1/8" Turning, and 3/4" Ogee Bending | 0000000 | 000000000 | ||

Tear-Preventing Sheet Metal Bender/Crimpers

|

Throat Dp. | Jaw Wd. | Lg. | Material | Each | ||

|---|---|---|---|---|---|---|

| 1" | 3 1/2" | 8" | Steel | 0000000 | 0000000 |

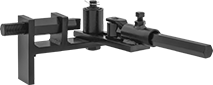

Wire, Rod, and Flat Stock Bender for Complex Shapes

For Max. Flat Stock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Wire Dia. | Thk. | Wd. | For Max. Rod Dia. | Material | Lg. | Wd. | Ht. | Handle Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3125" | 0.125" | 1" | 0.3125" | Steel | 9.5" | 2.5" | 3.5" | 12" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||