Filter by

Material

Shape

Thickness

Screw Size

Backing Type

Military Specification

Temper Rating

Sold As

Container Type

Container Depth

Minimum Hardness

Fabrication

Magnetic Properties

Export Control Classification Number (ECCN)

RoHS

DFARS Specialty Metals

Shim Stock Assortments

When you don’t know the exact shim thickness you’ll need, keep shim stock in multiple thicknesses on hand so you always have the right one. Cut this shim stock into custom shapes to create shims that suit your needs. With thickness tolerances as fine as a strand of hair, the shims will precisely align, space, and level components on dies, presses, and machinery.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

Shim Stock

|

Bronze—The choice for marine environments, it won't rust or deteriorate from exposure to salt water. It offers better corrosion resistance than 316 stainless steel but isn't as strong.

No. of Pieces | Includes | Wd. | Lg. | Specs. Met | Form | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | One 0.005" thick (±0.0003") sheet One 0.008" thick (±0.0004") sheet One 0.01" thick (±0.0007") sheet One 0.013" thick (±0.001") sheet One 0.016" thick (±0.001") sheet One 0.02" thick (±0.001") sheet One 0.025" thick (±0.001") sheet One 0.032" thick (±0.0015") sheet | 6" | 12" | ASTM B103 | Sheet | 9300K6 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shim Stock with Metal Cabinet

|

This shim stock comes in a spacious keyed-lock steel cabinet that can also be used to store your own tools and supplies.

No. of Pieces | Includes | Wd. | Lg. | Form | Each | |||

|---|---|---|---|---|---|---|---|---|

| 59 | 18-8 Stainless Steel—Hardened: 0.001", 0.0015", 0.002", 0.003", 0.004", 0.005", 0.006", 0.007", 0.008", 0.01", 0.012", 0.015" 1010 Low-Carbon Steel—Hardened: 0.001", 0.0015", 0.002", 0.003", 0.004", 0.005", 0.006", 0.007", 0.008", 0.01", 0.012", 0.015" 1095 Spring Steel—Hardened: 0.005", 0.01", 0.015", 0.02", 0.025", 0.032" 1100 Aluminum—Hardened: 0.001", 0.002", 0.003", 0.005" 260 Brass—Hardened: 0.001", 0.0015", 0.002", 0.003", 0.004", 0.005", 0.006", 0.007", 0.008", 0.01", 0.012", 0.015" 510 Bronze—Spring-Tempered: 0.005", 0.008", 0.01", 0.013", 0.016", 0.02", 0.025", 0.032" 110 Copper—Softened: 0.005", 0.01", 0.015", 0.02", 0.025" | 6" | 12" | Sheet, Roll | 9300K59 | 0000000 | ||

Shim Stock

|

Cut into custom shapes to create shims that suit your needs. With thickness tolerances as fine as a strand of hair, the shims will precisely align, space, and level components on dies, presses, and machinery.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

Bronze—The choice for marine environments, it won't rust or deteriorate from exposure to salt water. It offers better corrosion resistance than 316 stainless steel but isn't as strong.

Temper Rating—Choose half hard to create shims that you’ll need to bend or shape. Opt for full hard to make stronger shims that will maintain their shape

under loads.

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Temper Rating | Type | Form | Specs. Met | Form | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.016" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103, SAE AMS4510 | Sheet | 9014K313 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103, SAE AMS4510 | Sheet | 9014K315 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.025" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103, SAE AMS4510 | Sheet | 9014K317 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | Spring | Material Certificate | Paper | ASTM B103, SAE AMS4510 | Sheet | 9014K319 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0003" to 0.0003" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.01" | -0.0007" to 0.0007" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.013" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.016" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.025" | -0.001" to 0.001" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | Spring | Material Certificate | Paper | ASTM B103 | Roll | 9020K18 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.04" | -0.002" to 0.002" | Spring | Material Certificate | Paper | ASTM B103 | Sheet | 9020K19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

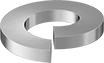

General Purpose Washers

Your go-to metal washer for every screw size. Washers take the pressure off nuts and screws to protect mounting surfaces.

Bronze

|

Super-Corrosion-Resistant Silicon Bronze—The choice for marine environments, these washers won't rust or deteriorate when submerged in salt water. They have better corrosion resistance than 316 stainless steel, but are not quite as strong.

For Screw Size | ID | OD | Thk. | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Silicon Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.147" | 0.375" | 0.025" to 0.039" | 100 | 93490A007 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.172" | 0.375" | 0.025" to 0.039" | 100 | 93490A009 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.200" | 0.438" | 0.029" to 0.043" | 100 | 93490A011 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.228" | 0.500" | 0.033" to 0.047" | 50 | 93490A013 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.260" | 0.688" | 0.033" to 0.047" | 50 | 93490A029 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.340" | 0.750" | 0.055" to 0.069" | 25 | 93490A017 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.392" | 0.875" | 0.055" to 0.069" | 25 | 93490A018 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.500" | 1.125" | 0.055" to 0.069" | 10 | 93490A032 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.562" | 1.250" | 0.071" to 0.085" | 10 | 93490A033 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.688" | 1.500" | 0.084" to 0.098" | 5 | 93490A035 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.812" | 1.875" | 0.095" to 0.109" | 1 | 93490A036 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.938" | 2.250" | 0.107" to 0.121" | 1 | 93490A037 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.062" | 2.500" | 0.121" to 0.135" | 1 | 93490A038 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mil. Spec. Tooth Lock Washers

These washers are manufactured and tested to strict U.S. military standards for material and construction. They resist vibration better than split lock washers to prevent nuts and screws from loosening in applications with constant movement, such as conveyors. Tooth lock washers typically can't be reused because the teeth often get bent when tightened.

External Tooth

|

Teeth on the outside edge bite into both the fastener and the mating surface for a stronger hold than internal-tooth lock washers. However, they may mar your material and snag on objects. Pair these washers with nuts and screws that are large enough to make contact with the teeth, such as pan, button, and binding head screws.

Super-Corrosion-Resistant Phosphor Bronze—Stronger and more wear resistant than silicon bronze, but with the same excellent corrosion resistance. These washers won't rust or deteriorate when submerged in salt water, so they're a good fit for marine environments.

For Screw Size | ID | OD | Thk. | Mil. Spec. | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.195" | 0.410" | 0.020" to 0.025" | MS35335-88 | ASME B18.21.1 | 25 | 97775A534 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.256" | 0.510" | 0.023" to 0.028" | MS35335-89 | ASME B18.21.1 | 10 | 97775A535 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.320" | 0.610" | 0.028" to 0.034" | MS35335-90 | ASME B18.21.1 | 10 | 97775A536 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.384" | 0.694" | 0.032" to 0.040" | MS35335-91 | ASME B18.21.1 | 10 | 97775A537 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.513" | 0.900" | 0.037" to 0.045" | MS35335-93 | ASME B18.21.1 | 10 | 97775A538 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Tooth

|

Internal teeth dig into the nut or screw to prevent it from backing out. Unlike external-tooth lock washers, these have a smooth outside edge, so they are less likely to mar your material or snag on objects. However, they don’t grip quite as well. Pair them with fasteners that have small diameters, such as fillister and cheese head screws.

Super-Corrosion-Resistant Phosphor Bronze—Stronger and more wear resistant than silicon bronze, but with the same excellent corrosion resistance. These washers won't rust or deteriorate when submerged in salt water, so they're a good fit for marine environments.

For Screw Size | ID | OD | Thk. | Mil. Spec. | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 | 0.089" | 0.200" | 0.010" to 0.015" | MS35333-103 | ASME B18.21.1, NASM35333 | 25 | 96551A340 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.115" | 0.270" | 0.015" to 0.019" | MS35333-104 | ASME B18.21.1, NASM35333 | 25 | 96551A350 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.141" | 0.295" | 0.017" to 0.021" | MS35333-105 | ASME B18.21.1, NASM35333 | 25 | 96551A360 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.168" | 0.340" | 0.018" to 0.023" | MS35333-106 | ASME B18.21.1, NASM35333 | 25 | 96551A370 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.195" | 0.381" | 0.020" to 0.025" | MS35333-107 | ASME B18.21.1, NASM35333 | 25 | 96551A380 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.256" | 0.478" | 0.023" to 0.028" | MS35333-108 | ASME B18.21.1, NASM35333 | 25 | 96551A390 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.332" | 0.610" | 0.028" to 0.034" | MS35333-109 | ASME B18.21.1, NASM35333 | 10 | 96551A400 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.384" | 0.692" | 0.032" to 0.040" | MS35333-110 | ASME B18.21.1, NASM35333 | 10 | 96551A410 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.512" | 0.900" | 0.037" to 0.045" | MS35333-113 | ASME B18.21.1, NASM35333 | 5 | 96551A420 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

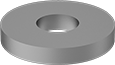

Split Lock Washers

|

Stop nuts and screws from loosening due to mild vibration. As you tighten, the uneven ends bite into the nut or screw so it won't back out. While they're not as vibration resistant as other lock washers, they are a great fit for electrical panels, light fixtures, and other light duty assemblies. Split lock washers are not reusable, and they only work with fasteners that have right-hand threads.

Super-Corrosion-Resistant Silicon Bronze—The choice for marine environments, these washers won't rust or deteriorate when submerged in salt water. They resist corrosion as well as 316 stainless steel, but are not quite as strong.

For Screw Size | ID | OD | Thk. | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Silicon Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 | 0.094" | 0.172" | 0.020" | ASME B18.21.1 | 100 | 93496A403 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 3 | 0.107" | 0.195" | 0.025" | ASME B18.21.1 | 100 | 93496A404 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.120" | 0.209" | 0.025" | ASME B18.21.1 | 100 | 93496A405 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.120" | 0.209" | 0.025" | ASME B18.21.1 | 1,000 | 93496A005 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.148" | 0.250" | 0.031" | ASME B18.21.1 | 100 | 93496A407 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.148" | 0.250" | 0.031" | ASME B18.21.1 | 1,000 | 93496A007 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.174" | 0.293" | 0.040" | ASME B18.21.1 | 100 | 93496A409 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.174" | 0.293" | 0.040" | ASME B18.21.1 | 1,000 | 93496A009 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.200" | 0.334" | 0.047" | ASME B18.21.1 | 100 | 93496A415 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.227" | 0.377" | 0.056" | ASME B18.21.1 | 100 | 93496A418 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.260" | 0.487" | 0.062" | ASME B18.21.1 | 100 | 93496A029 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.322" | 0.583" | 0.078" | ASME B18.21.1 | 50 | 93496A030 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.385" | 0.680" | 0.094" | ASME B18.21.1 | 25 | 93496A031 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.450" | 0.776" | 0.109" | ASME B18.21.1 | 10 | 93496A432 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.512" | 0.869" | 0.125" | ASME B18.21.1 | 10 | 93496A433 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.641" | 1.073" | 0.156" | ASME B18.21.1 | 5 | 93496A435 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.766" | 1.265" | 0.188" | ASME B18.21.1 | 5 | 93496A436 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.024" | 1.656" | 0.250" | ASME B18.21.1 | 5 | 93496A445 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.4 mm | 6.2 mm | 0.7 mm to 0.9 mm | DIN 127B | 100 | 97093A201 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.4 mm | 7.6 mm | 0.8 mm to 1.0 mm | DIN 127B | 100 | 97093A202 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.4 mm | 9.2 mm | 1.1 mm to 1.3 mm | DIN 127B | 100 | 97093A203 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.5 mm | 11.8 mm | 1.5 mm to 1.7 mm | DIN 127B | 50 | 97093A204 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.5 mm | 14.8 mm | 1.9 mm to 2.1 mm | DIN 127B | 25 | 97093A205 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.7 mm | 18.1 mm | 2.0 mm to 2.4 mm | DIN 127B | 10 | 97093A206 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

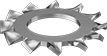

Tooth Lock Washers

Grip tighter than split lock washers to prevent nuts and screws from loosening in applications with constant movement, such as conveyors. Tooth lock washers typically can't be reused because the teeth often get bent when tightened.

External Tooth

|

Teeth on the outside edge bite into both the fastener and the mating surface for a stronger hold than internal-tooth lock washers. However, they may mar your material and snag on objects. Pair these washers with nuts and screws that are large enough to make contact with the teeth, such as pan, button, and binding head screws.

Super-Corrosion-Resistant Phosphor Bronze—Stronger and more wear resistant than silicon bronze, but with the same excellent corrosion resistance. These washers won't rust or deteriorate when submerged in salt water, so they're a good fit for marine environments.

For Screw Size | ID | OD | Thk. | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 3 | 0.102" | 0.235" | 0.010" to 0.016" | ASME B18.21.1 | 100 | 92164A333 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.115" | 0.260" | 0.012" to 0.018" | ASME B18.21.1 | 100 | 92164A005 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.141" | 0.320" | 0.016" to 0.022" | ASME B18.21.1 | 100 | 92164A007 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.168" | 0.381" | 0.018" to 0.023" | ASME B18.21.1 | 100 | 92164A009 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.195" | 0.410" | 0.018" to 0.024" | ASME B18.21.1 | 100 | 92164A011 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.221" | 0.475" | 0.020" to 0.027" | ASME B18.21.1 | 100 | 92164A334 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.256" | 0.510" | 0.023" to 0.028" | ASME B18.21.1 | 100 | 92164A029 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.320" | 0.610" | 0.028" to 0.034" | ASME B18.21.1 | 50 | 92164A030 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.384" | 0.694" | 0.032" to 0.040" | ASME B18.21.1 | 25 | 92164A031 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.448" | 0.760" | 0.032" to 0.040" | ASME B18.21.1 | 25 | 92164A032 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.513" | 0.900" | 0.037" to 0.045" | ASME B18.21.1 | 25 | 92164A033 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.641" | 1.070" | 0.042" to 0.050" | ASME B18.21.1 | 10 | 92164A040 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.768" | 1.260" | 0.047" to 0.055" | ASME B18.21.1 | 5 | 92164A335 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Tooth

|

Internal teeth dig into the nut or screw to prevent it from backing out. Unlike external-tooth lock washers, these have a smooth outside edge, so they are less likely to mar your material or snag on objects. However, they don’t grip quite as well. Pair them with fasteners that have small diameters, such as fillister and cheese head screws.

Super-Corrosion-Resistant Phosphor Bronze—Stronger and more wear resistant than silicon bronze, but with the same excellent corrosion resistance. These washers won't rust or deteriorate when submerged in salt water, so they're a good fit for marine environments.

For Screw Size | ID | OD | Thk. | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 | 0.089" | 0.200" | 0.010" to 0.016" | ASME B18.21.1 | 100 | 92165A002 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 3 | 0.109" | 0.232" | 0.010" to 0.016" | ASME B18.21.1 | 100 | 92165A121 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.115" | 0.270" | 0.012" to 0.018" | ASME B18.21.1 | 100 | 92165A005 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 5 | 0.136" | 0.280" | 0.014" to 0.018" | ASME B18.21.1 | 100 | 92165A122 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.141" | 0.295" | 0.016" to 0.022" | ASME B18.21.1 | 100 | 92165A007 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.168" | 0.340" | 0.018" to 0.023" | ASME B18.21.1 | 100 | 92165A009 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.195" | 0.381" | 0.018" to 0.024" | ASME B18.21.1 | 100 | 92165A011 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.231" | 0.410" | 0.020" to 0.027" | ASME B18.21.1 | 100 | 92165A123 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.256" | 0.478" | 0.023" to 0.028" | ASME B18.21.1 | 100 | 92165A029 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.320" | 0.610" | 0.028" to 0.034" | ASME B18.21.1 | 50 | 92165A030 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.384" | 0.692" | 0.032" to 0.040" | ASME B18.21.1 | 50 | 92165A031 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.448" | 0.789" | 0.032" to 0.040" | ASME B18.21.1 | 25 | 92165A032 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.512" | 0.900" | 0.037" to 0.045" | ASME B18.21.1 | 25 | 92165A033 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.640" | 1.071" | 0.042" to 0.050" | ASME B18.21.1 | 5 | 92165A055 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.795" | 1.245" | 0.047" to 0.055" | ASME B18.21.1 | 5 | 92165A124 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

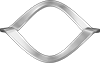

Wave Spring Lock Washers

|

The wavy shape flexes like a spring to keep nuts and screws secure on slightly uneven surfaces. These washers add a small amount of tension to stop fasteners from backing out due to mild vibration. While they don't hold as well as other lock washers, they do grip slightly better than curved washers. They work best in electrical panels, light fixtures, and other light duty assemblies. Since these washers hold their shape when untightened, you can reuse them a handful of times without losing strength.

Super-Corrosion-Resistant Phosphor Bronze—Stronger and more wear resistant than silicon bronze, but with the same excellent corrosion resistance. These washers won't rust or deteriorate when submerged in salt water, so they're a good fit for marine environments.

For Screw Size | No. of Waves | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 1 | 3.2 | 8.0 | 0.5 | 1.6 | DIN 137B | 25 | 90394A111 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 1 | 4.3 | 9.0 | 0.5 | 2.0 | DIN 137B | 25 | 90394A112 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 1 | 5.3 | 11.0 | 0.5 | 2.2 | DIN 137B | 10 | 90394A113 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 1 | 6.4 | 12.0 | 0.5 | 2.6 | DIN 137B | 10 | 90394A114 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 1 | 8.4 | 15.0 | 0.8 | 3.0 | DIN 137B | 5 | 90394A115 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 1 | 10.5 | 21.0 | 1.0 | 4.2 | DIN 137B | 1 | 90394A116 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 1 | 13.0 | 24.0 | 1.2 | 5.0 | DIN 137B | 1 | 90394A117 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oversized Washers

These washers have exaggerated diameters to cover large holes and to compensate for uneven mounting surfaces. They are also thicker than general purpose washers, so they bridge wide gaps when used as spacers.

Bronze

|

Super-Corrosion-Resistant Silicon Bronze—The choice for marine environments, these washers won't rust or deteriorate when submerged in salt water. They have better corrosion resistance than 316 stainless steel, but are not quite as strong.