Filter by

System of Measurement

Thickness

ID

OD

Hardness

Magnetic Properties

Performance

Minimum Hardness

Sold As

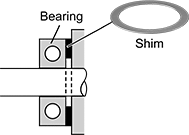

Shims for Ball Bearing Outer Rings

For Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | ID | OD | ID | ID Tolerance | OD | OD Tolerance | Min. Hardness | Thk. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R0 | 3/64" | 5/32" | 0.088" | 0" to 0.005" | 0.153" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1 | 0.055" | 3/16" | 0.123" | 0" to 0.005" | 0.178" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1-4, R144 | 5/64", 1/8" | 1/4" | 0.167" | 0" to 0.005" | 0.248" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1-5, R2-5 | 3/32", 1/8" | 5/16" | 0.206" | 0" to 0.005" | 0.31" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R2, R166 | 1/8", 3/16" | 3/8" | 0.253" | 0" to 0.005" | 0.373" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R3, R188 | 3/16", 1/4" | 1/2" | 0.378" | 0" to 0.005" | 0.498" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R4 | 1/4" | 5/8" | 0.503" | 0" to 0.005" | 0.623" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R6 | 3/8" | 7/8" | 0.687" | 0" to 0.005" | 0.873" | -0.005" to 0" | Rockwell B70 | 0.003" | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1 | 0.055" | 3/16" | 0.123" | 0" to 0.005" | 0.178" | -0.005" to 0" | Rockwell B70 | 0.003" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1-4, R144 | 5/64", 1/8" | 1/4" | 0.167" | 0" to 0.005" | 0.248" | -0.005" to 0" | Rockwell B70 | 0.003" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R1-5, R2-5 | 3/32", 1/8" | 5/16" | 0.206" | 0" to 0.005" | 0.31" | -0.005" to 0" | Rockwell B70 | 0.003" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R2, R166 | 1/8", 3/16" | 3/8" | 0.253" | 0" to 0.005" | 0.373" | -0.005" to 0" | Rockwell B70 | 0.003" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R3, R188 | 3/16", 1/4" | 1/2" | 0.378" | 0" to 0.005" | 0.498" | -0.005" to 0" | Rockwell B70 | 0.003" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R4 | 1/4" | 5/8" | 0.503" | 0" to 0.005" | 0.623" | -0.005" to 0" | Rockwell B70 | 0.003" | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shim Stock

|

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Temper Rating | Color | Type | Form | Specs. Met | Form | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Sheet | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Sheet | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A240, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 17-7 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM A693 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Strength 17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4" Wide × 60" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM A693 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 60" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 180" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | Full Hard | — | Material Certificate | Paper | ASTM A682, ASTM A684, MIL-S-7947 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM B209 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Full Hard | — | Material Certificate | Paper | ASTM B209 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard to Full Hard | Green | Material Certificate | Paper | — | Sheet | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard to Full Hard | Green | Material Certificate | Paper | — | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 60" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Sheet | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | — | Material Certificate | Paper | ASTM B152 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | — | Material Certificate | Paper | ASTM B152 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | — | Material Certificate | Paper | ASTM B152 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM B160, ASTM B162, ASTM B163 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | — | — | Material Certificate | Paper | ASTM B160, ASTM B162, ASTM B163 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Chemical-Resistant PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | White | — | — | ASTM D3308, MIL-P-22241 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | White | — | — | ASTM D3308, MIL-P-22241 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | White | — | — | ASTM D3308, MIL-P-22241 | Sheet | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | White | — | — | ASTM D3308, MIL-P-22241 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | — | White | — | — | ASTM D3308, MIL-P-22241 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5" Wide × 20" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0002" to 0.0002" | — | Green | — | — | — | Sheet | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10" Wide × 20" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0002" to 0.0002" | — | Green | — | — | — | Sheet | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0002" to 0.0002" | — | Green | — | — | — | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20" Wide × 20" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0002" to 0.0002" | — | Green | — | — | — | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0002" to 0.0002" | — | Green | — | — | — | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0002" to 0.0002" | — | Green | — | — | — | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shims

|

Thk. | Thk. Tolerance | ID Tolerance | OD Tolerance | Min. Hardness | Color | Certificate Type | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/32" ID × 7/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/64" ID × 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/16" ID × 5/32" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/64" ID × 5/32" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/32" ID × 13/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | Material Certificate | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | Material Certificate | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" ID × 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | Material Certificate | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11/32" ID × 13/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 9/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" ID × 1 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/8" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" ID × 19/32" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11/32" ID × 13/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11/32" ID × 13/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" ID × 1 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/8" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/32" ID × 13/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" ID × 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 9/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | Material Certificate | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Color-Coded Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 0" to 0.015" | -0.005" to 0.005" | — | Green | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

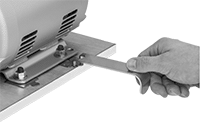

Slotted Shims

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot | Each | Package | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk. | Thk. Tolerance | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | Color | End Shape | Each | Pkg. Qty. | Pkg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Lg. × 1" Wd. (Shim Trade Size AAA) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1/4" | 5/16" | 5/8" | Rockwell C42 | Labeled | — | Tab | 000000000 | 00000 | 20 | 000000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" Lg. × 1 1/2" Wd. (Shim Trade Size AA) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 3/8" | 7/16" | 61/64" | Rockwell B85 | Labeled | — | Tab | 000000000 | 0000 | 20 | 000000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" Lg. × 2" Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1/2" | 9/16" | 1 9/32" | Rockwell B85 | Labeled | — | Tab | 0000000 | 0000 | 20 | 00000000 | 00000 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 1/2" Lg. × 2 1/2" Wd. (Shim Trade Size BB) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 5/8" | 11/16" | 1 19/32" | Rockwell B85 | Labeled | — | Tab | 000000000 | 0000 | 20 | 000000000 | 00000 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" Lg. × 3" Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 3/4" | 13/16" | 1 29/32" | Rockwell B85 | Labeled | — | Tab | 0000000 | 0000 | 20 | 00000000 | 00000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4" Lg. × 4" Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1 1/8" | 1 3/16" | 2 19/32" | Rockwell B85 | Labeled | — | Tab | 0000000 | 0000 | 20 | 00000000 | 00000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5" Lg. × 5" Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1 1/2" | 1 9/16" | 3 9/32" | Rockwell B85 | Labeled | — | Tab | 0000000 | 0000 | 20 | 00000000 | 00000 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 5" Wd. (Shim Trade Size DD) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1 1/2" | 1 9/16" | 4 1/2" | Rockwell C42 | Labeled | — | Tab | 000000000 | 0000 | 20 | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 6" Wd. (Shim Trade Size E) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 1 7/8" | 1 15/16" | 4" | Rockwell B85 | Labeled | — | Tab | 000000000 | 0000 | 20 | 000000000 | 00000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 6" Wd. (Shim Trade Size G) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 2 1/4" | 2 5/16" | 4 3/16" | Rockwell B85 | Labeled | — | Tab | 000000000 | 0000 | 20 | 000000000 | 00000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Lg. × 8" Wd. (Shim Trade Size H) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | 2 1/4" | 2 5/16" | 5 3/16" | Rockwell B85 | Labeled | — | Tab | 000000000 | 0000 | 20 | 000000000 | 000000 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" Lg. × 1 1/2" Wd. (Shim Trade Size AA) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 5/16" | 3/8" | 15/16" | Not Rated | Color Coded | Green | Square | ——— | 0 | 20 | 00000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" Lg. × 2" Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 3/8" | 7/16" | 1 7/32" | Not Rated | Color Coded | Green | Square | ——— | 0 | 20 | 0000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" Lg. × 3" Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2" | 9/16" | 1 25/32" | Not Rated | Color Coded | Green | Square | ——— | 0 | 20 | 0000000 | 0000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4" Lg. × 4" Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 7/8" | 1" | 2 1/2" | Not Rated | Color Coded | Green | Square | ——— | 0 | 20 | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesive-Back Shim Stock

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Material Thk. | Adhesive Thk. | Adhesive Type | Temper Rating | Type | Form | Specs. Met | Form | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00005" to 0.00005" | 0.001" | 0.002" | Acrylic | Full Hard | Material Certificate | Digital | ASTM A666 | Sheet | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0001" to 0.0001" | 0.001" | 0.002" | Acrylic | — | Material Certificate | Digital | ASTM B479 | Sheet | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0001" to 0.0001" | 0.001" | 0.002" | Acrylic | 1/2 Hard | Material Certificate | Digital | ASTM B36 | Sheet | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Made-to-Order Shims

|

2" × 2" Maximum Shim Size | 5" × 5" Maximum Shim Size | 7" × 7" Maximum Shim Size | 11" × 11" Maximum Shim Size | 23" × 23" Maximum Shim Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Min. Hardness | Certificate Type | Specs. Met | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Rockwell C42 | Material Certificate | ASTM A240 | 16 | 000000000 | 000000 | 4 | 000000000 | 000000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Not Rated | Material Certificate | ASTM A240, Fed. Spec. QQ-S-766 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Rockwell B90 | Material Certificate | ASTM A109, Fed. Spec. QQ-S-698 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.00015" to 0.00015" | Rockwell B60 | Material Certificate | ASTM B36, Fed. Spec. QQ-B-613 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shims for D-Profile Shafts

Thk. | Thk. Tolerance | ID | ID Tolerance | OD | OD Tolerance | Flat Wd. | Min. Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/8" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 0.385" | -0.01" to 0.01" | 5/8" | -0.01" to 0.01" | 0.173" | Rockwell B90 | 5 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1/2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 0.51" | -0.01" to 0.01" | 3/4" | -0.01" to 0.01" | 0.235" | Rockwell B90 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 5/8" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 0.635" | -0.01" to 0.01" | 1" | -0.01" to 0.01" | 0.298" | Rockwell B90 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 0.76" | -0.01" to 0.01" | 1 1/8" | -0.01" to 0.01" | 0.36" | Rockwell B90 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1.01" | -0.01" to 0.01" | 1 1/2" | -0.01" to 0.01" | 0.485" | Rockwell B90 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1.26" | -0.01" to 0.01" | 1 3/4" | -0.01" to 0.01" | 0.61" | Rockwell B90 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shims for Keyed Shafts

Notch

Notch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | ID | ID Tolerance | OD | OD Tolerance | Wd. | Dp. | Min. Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1/2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1/2" | 0" to 0.011" | 3/4" | -0.002" to 0.002" | 1/8" | 3/64" | Rockwell B80 | 10 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 3/4" | 0" to 0.011" | 1 1/8" | -0.002" to 0.002" | 3/16" | 5/64" | Rockwell B80 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 7/8" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 7/8" | 0" to 0.011" | 1 3/8" | -0.002" to 0.002" | 3/16" | 5/64" | Rockwell B80 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1" | 0" to 0.011" | 1 1/2" | -0.002" to 0.002" | 1/4" | 3/32" | Rockwell B80 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1 1/4" | 0" to 0.011" | 1 3/4" | -0.002" to 0.002" | 5/16" | 1/8" | Rockwell B80 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1 1/2" | 0" to 0.011" | 2 1/8" | -0.002" to 0.002" | 3/8" | 5/32" | Rockwell B80 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 2" | 0" to 0.011" | 2 3/4" | -0.002" to 0.002" | 1/2" | 3/16" | Rockwell B80 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 5/8" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 5/8" | 0" to 0.011" | 1" | -0.002" to 0.002" | 3/16" | 1/16" | Rockwell B84 | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 3/4" | 0" to 0.011" | 1 1/8" | -0.002" to 0.002" | 3/16" | 5/64" | Rockwell B84 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 7/8" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 7/8" | 0" to 0.011" | 1 3/8" | -0.002" to 0.002" | 3/16" | 5/64" | Rockwell B84 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1" | 0" to 0.011" | 1 1/2" | -0.002" to 0.002" | 1/4" | 3/32" | Rockwell B84 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1 1/4" | 0" to 0.011" | 1 3/4" | -0.002" to 0.002" | 5/16" | 1/8" | Rockwell B84 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 1 1/2" | 0" to 0.011" | 2 1/8" | -0.002" to 0.002" | 3/8" | 5/32" | Rockwell B84 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.003" | -0.0003" to 0.0003" | 2" | 0" to 0.011" | 2 3/4" | -0.002" to 0.002" | 1/2" | 3/16" | Rockwell B84 | 5 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||