Filter by

System of Measurement

Thickness

ID

OD

Magnetic Properties

Minimum Hardness

Performance

Material Thickness

Specifications Met

Hardness

Sold As

Certificate Type

Shims

|

Thk. | Thk. Tolerance | ID Tolerance | OD Tolerance | Min. Hardness | Certificate Type | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/32" ID × 7/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/64" ID × 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/16" ID × 5/32" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/64" ID × 5/32" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/32" ID × 13/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" ID × 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11/32" ID × 13/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 9/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" ID × 1 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/8" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | — | ASTM A240 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/32" ID × 13/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" ID × 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 9/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B90 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" ID × 1 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/8" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 2 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B65 | — | — | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/32" ID × 13/64" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" ID × 3/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" ID × 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | Material Certificate | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" ID × 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 9/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | 0" to 0.005" | -0.005" to 0.005" | Rockwell B70 | — | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shim Stock

|

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Temper Rating | Color | Type | Form | Specs. Met | Form | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Sheet | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1/2 Hard | — | Material Certificate | Paper | ASTM A666 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5913 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A666, SAE AMS5906, SAE AMS5913 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Roll | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A240, ASTM A666, SAE AMS5507, SAE AMS5524 | Sheet | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 17-7 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM A693 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Strength 17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4" Wide × 60" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM A693 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 180" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | Full Hard | — | Material Certificate | Paper | — | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.00075" to 0.00075" | Full Hard | — | Material Certificate | Paper | ASTM A109 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | Full Hard | — | Material Certificate | Paper | ASTM A684, SAE AMS5122 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 25" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | Full Hard | — | Material Certificate | Paper | ASTM A684, SAE AMS5122 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | Full Hard | — | Material Certificate | Paper | ASTM A682, ASTM A684, MIL-S-7947 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | Full Hard | — | Material Certificate | Paper | ASTM A684, SAE AMS5122 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.0005" | Full Hard | — | Material Certificate | Paper | ASTM A684, SAE AMS5122 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM B209 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Full Hard | — | Material Certificate | Paper | ASTM B209 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 60" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Sheet | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 120" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1/2 Hard | — | Material Certificate | Paper | ASTM B36 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Spring | — | Material Certificate | Paper | ASTM B103 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM B152 | Roll | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 100" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM B152 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | — | — | Material Certificate | Paper | ASTM B152 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | — | — | Material Certificate | Paper | ASTM B265 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | — | — | Material Certificate | Paper | ASTM B265 | Roll | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Chemical-Resistant PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 50" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | — | White | — | — | ASTM D3308, MIL-P-22241 | Roll | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | — | White | — | — | ASTM D3308, MIL-P-22241 | Sheet | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

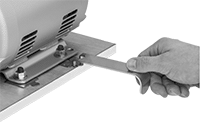

Slotted Shims

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot | Each | Package | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk. | Thk. Tolerance | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | End Shape | Each | Pkg. Qty. | Pkg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" Lg. × 1 1/2" Wd. (Shim Trade Size AA) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 3/8" | 7/16" | 61/64" | Rockwell C42 | Labeled | Tab | 000000000 | 00000 | 20 | 000000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" Lg. × 2" Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1/2" | 9/16" | 1 9/32" | Rockwell C42 | Labeled | Tab | 00000000 | 0000 | 20 | 00000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 1/2" Lg. × 2 1/2" Wd. (Shim Trade Size BB) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 5/8" | 11/16" | 1 19/32" | Rockwell C42 | Labeled | Tab | 000000000 | 0000 | 20 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" Lg. × 3" Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 3/4" | 13/16" | 1 29/32" | Rockwell C42 | Labeled | Tab | 00000000 | 0000 | 20 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4" Lg. × 4" Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1 1/8" | 1 3/16" | 2 19/32" | Rockwell C42 | Labeled | Tab | 00000000 | 0000 | 20 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5" Lg. × 5" Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1 1/2" | 1 9/16" | 3 9/32" | Rockwell C42 | Labeled | Tab | 00000000 | 0000 | 20 | 00000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 6" Wd. (Shim Trade Size E) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 1 7/8" | 1 15/16" | 4" | Rockwell C42 | Labeled | Tab | 000000000 | 0000 | 20 | 000000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 6" Wd. (Shim Trade Size G) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 2 1/4" | 2 5/16" | 4 3/16" | Rockwell C42 | Labeled | Tab | 000000000 | 0000 | 20 | 000000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Lg. × 8" Wd. (Shim Trade Size H) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 2 1/4" | 2 5/16" | 5 3/16" | Rockwell C42 | Labeled | Tab | 000000000 | 0000 | 20 | 000000000 | 000000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

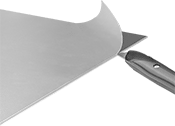

Peel-Away Multilayer Shim Stock

|

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | No. of Layers | Layer Thk. | Temper Rating | Type | Form | Specs. Met | Form | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 4 | 0.002" | — | — | — | SAE AMS-DTL-22499 | Sheet | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 4 | 0.002" | — | — | — | SAE AMS-DTL-22499 | Sheet | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 4 | 0.002" | — | — | — | Fed. Spec. QQ-S-698, SAE AMS-DTL-22499 | Sheet | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 4 | 0.002" | — | — | — | Fed. Spec. QQ-S-698, SAE AMS-DTL-22499 | Sheet | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 4 | 0.002" | Full Hard | — | — | SAE AMS-DTL-22499 | Sheet | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 4 | 0.002" | 1/2 Hard | — | — | SAE AMS-DTL-22499 | Sheet | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyimide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 2 | 0.004" | — | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesive-Back Shim Stock

|

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Material Thk. | Adhesive Thk. | Adhesive Type | Temper Rating | Type | Form | Specs. Met | Form | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0003" to 0.0003" | 0.006" | 0.002" | Acrylic | Full Hard | Material Certificate | Digital | ASTM A666 | Sheet | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0003" to 0.0003" | 0.006" | 0.002" | Acrylic | — | Material Certificate | Digital | ASTM A666 | Sheet | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0006" to 0.0006" | 0.006" | 0.002" | Acrylic | — | Material Certificate | Digital | ASTM B209 | Sheet | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0006" to 0.0006" | 0.006" | 0.002" | Acrylic | 1/2 Hard | Material Certificate | Digital | ASTM B36 | Sheet | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Made-to-Order Shims

|

2" × 2" Maximum Shim Size | 5" × 5" Maximum Shim Size | 7" × 7" Maximum Shim Size | 11" × 11" Maximum Shim Size | 23" × 23" Maximum Shim Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Min. Hardness | Certificate Type | Specs. Met | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Rockwell C42 | Material Certificate | ASTM A240 | 16 | 000000000 | 000000 | 4 | 000000000 | 000000 | 9 | 000000000 | 0000000 | 4 | 000000000 | 0000000 | 1 | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Not Rated | Material Certificate | ASTM A240, Fed. Spec. QQ-S-766 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | Rockwell B90 | Material Certificate | ASTM A109, Fed. Spec. QQ-S-698 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 00000 | 4 | 000000000 | 00000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Peel-Away Multilayer Made-to-Order Shims

|

2" × 2" Maximum Shim Size | 5" × 5" Maximum Shim Size | 7" × 7" Maximum Shim Size | 11" × 11" Maximum Shim Size | 23" × 23" Maximum Shim Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | No. of Layers | Layer Thk. | Min. Hardness | Certificate Type | Specs. Met | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 4 | 0.002" | Rockwell B80 | Material Certificate | ASTM A240 | 16 | 000000000 | 0000000 | 4 | 000000000 | 0000000 | 9 | 000000000 | 0000000 | 4 | 000000000 | 0000000 | 1 | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 4 | 0.002" | Rockwell B54 | Material Certificate | Fed. Spec. QQ-S-698 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 4 | 0.002" | Not Rated | Material Certificate | ASTM B209, SAE AMS-DTL-22499 | 16 | 000000000 | 00000 | 4 | 000000000 | 00000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0004" to 0.0004" | 4 | 0.002" | Not Rated | Material Certificate | ASTM B36 | 16 | 000000000 | 000000 | 4 | 000000000 | 000000 | 9 | 000000000 | 000000 | 4 | 000000000 | 000000 | 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wave Spring Lock Washers

|

For Screw Size | No. of Waves | ID | OD | Thk. | Overall Ht. | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 1 | 0.121" | 0.240" | 0.008" | 0.056" | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 1 | 0.121" | 0.240" | 0.008" | 0.056" | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 1 | 0.118" | 0.240" | 0.008" | 0.056" | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 1 | 0.160" | 0.438" | 0.008" | 0.103" | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 3 | 0.214" | 0.250" | 0.008" | 0.050" | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 | 0.269" | 0.423" | 0.008" | 0.070" | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shims for Keyed Shafts

Notch

Notch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | ID | ID Tolerance | OD | OD Tolerance | Wd. | Dp. | Min. Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 3/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 3/4" | 0" to 0.011" | 1 1/8" | -0.002" to 0.002" | 3/16" | 5/64" | Rockwell B80 | 10 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 7/8" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 7/8" | 0" to 0.011" | 1 3/8" | -0.002" to 0.002" | 3/16" | 5/64" | Rockwell B80 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1" | 0" to 0.011" | 1 1/2" | -0.002" to 0.002" | 1/4" | 3/32" | Rockwell B80 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/4" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1 1/4" | 0" to 0.011" | 1 3/4" | -0.002" to 0.002" | 5/16" | 1/8" | Rockwell B80 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 1 1/2" | 0" to 0.011" | 2 1/8" | -0.002" to 0.002" | 3/8" | 5/32" | Rockwell B80 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 2" Diameter Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0008" to 0.0008" | 2" | 0" to 0.011" | 2 3/4" | -0.002" to 0.002" | 1/2" | 3/16" | Rockwell B80 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||