Filter by

System of Measurement

ID

Thickness

OD

Performance

Minimum Hardness

Magnetic Properties

DFARS Specialty Metals

Hardness

Export Control Classification Number (ECCN)

Sold As

Shaft Type

Specifications Met

Shims

|

Thk., mm | Thk. Tolerance, mm | ID Tolerance, mm | OD Tolerance, mm | Min. Hardness | Color | Certificate Type | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm ID × 8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm ID × 10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.31 to 0.29 | -0.11 to -0.01 | Rockwell B70 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm ID × 20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm ID × 25 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22 mm ID × 30 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

35 mm ID × 45 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40 mm ID × 50 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

45 mm ID × 55 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm ID × 62 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.29 to 0.31 | -0.07 to 0.03 | Rockwell B70 | — | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

55 mm ID × 68 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.31 to 0.29 | -0.01 to 0.09 | Rockwell B70 | — | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60 mm ID × 75 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.31 to 0.29 | -0.12 to -0.02 | Rockwell B70 | — | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

70 mm ID × 90 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.13 to -0.03 | Rockwell B70 | — | — | — | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm ID × 8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm ID × 10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B70 | — | — | ASTM A240 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm ID × 20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm ID × 25 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B70 | — | — | ASTM A240 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm ID × 8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm ID × 10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm ID × 20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm ID × 25 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 100 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 50 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22 mm ID × 30 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 25 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 25 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 25 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

35 mm ID × 45 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 25 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40 mm ID × 50 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | Material Certificate | — | 25 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm ID × 62 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

55 mm ID × 68 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60 mm ID × 75 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 10 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

70 mm ID × 90 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

80 mm ID × 100 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | — | 10 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm ID × 8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm ID × 10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm ID × 20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm ID × 25 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22 mm ID × 30 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

35 mm ID × 45 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40 mm ID × 50 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

45 mm ID × 55 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm ID × 62 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

55 mm ID × 68 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60 mm ID × 75 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

70 mm ID × 90 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

80 mm ID × 100 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | — | DIN 988 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | Material Certificate | — | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40 mm ID × 50 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | — | ASTM B36 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | — | ASTM B152 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | — | ASTM B152 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | — | ASTM B152 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | — | ASTM B152 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | — | ASTM B152 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Chemical-Resistant PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | — | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.064 to 0.064 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

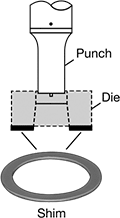

Shims for Dies

Thk., mm | Thk. Tolerance, mm | OD Tolerance, mm | ID, mm | ID Tolerance, mm | Min. Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.025 to 0.025 | -0.3 to 0 | 6 | -0.08 to 0.17 | Rockwell C40 | 25 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.025 to 0.025 | -0.3 to 0 | 8 | -0.18 to 0.07 | Rockwell C40 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.025 to 0.025 | -0.31 to 0 | 12 | -0.35 to 0 | Rockwell C40 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.025 to 0.025 | -0.32 to 0 | 16 | -0.5 to 0 | Rockwell C40 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

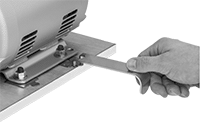

Slotted Shims

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot, mm | Each | Package | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk., mm | Thk. Tolerance, mm | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | Color | End Shape | Each | Pkg. Qty. | Pkg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm Lg. × 50 mm Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.032 to 0.032 | M15 | 15.9 | 25.4 | Rockwell C40 | Labeled | — | Tab | 00000000 | 00000 | 10 | 00000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

75 mm Lg. × 75 mm Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.032 to 0.032 | M22 | 22.3 | 38.1 | Rockwell C40 | Labeled | — | Tab | 00000000 | 0000 | 10 | 00000000 | 00000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

100 mm Lg. × 100 mm Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.032 to 0.032 | M30 | 31.8 | 50.8 | Rockwell C40 | Labeled | — | Tab | 00000000 | 0000 | 10 | 00000000 | 00000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

125 mm Lg. × 125 mm Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.032 to 0.032 | M40 | 41.3 | 84.1 | Rockwell C40 | Labeled | — | Tab | 00000000 | 00000 | 10 | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

65 mm Lg. × 25 mm Wd. (Shim Trade Size ASH105) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M10 | 10.5 | 60.25 | Rockwell B90 | Labeled | Yellow | Square | 000000000 | 0000 | — | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

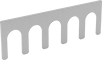

Multislotted Shims

Slot, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk., mm | Thk. Tolerance, mm | For Max. Screw Size | Wd. | Dp. | Lg., mm | Wd., mm | Shim Trade Size | Min. Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M10 | 10.5 | 17.8 | 25 | 34 | ASH205 | Not Rated | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M8 | 9 | 14.5 | 20 | 46 | ASH305N | Rockwell B90 | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M10 | 10.5 | 17.8 | 25 | 48 | ASH305 | Not Rated | 10 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M8 | 9 | 14.5 | 20 | 61 | ASH405N | Rockwell B90 | 10 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M10 | 10.5 | 17.8 | 25 | 63 | ASH405 | Not Rated | 10 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.03 to 0.03 | M10 | 10.5 | 17.8 | 25 | 78 | ASH505 | Not Rated | 10 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shim Stock

|

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk., mm | Thk. Tolerance, mm | Temper Rating | Type | Form | Specs. Met | Form | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 mm Wide × 1,250 mm Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.025 to 0.025 | Full Hard | Material Certificate | Paper | ASTM A666 | Roll | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 mm Wide × 2,500 mm Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | -0.025 to 0.025 | Full Hard | Material Certificate | Paper | ASTM A109, Fed. Spec. QQ-S-698 | Roll | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy-Vibration-Resistant Spring Lock Washers

|

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 | 2.7 | 6.0 | 0.5 | 0.7 | DIN 6796 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.2 | 8.0 | 0.5 | 0.7 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.2 | 10.0 | 0.5 | 0.8 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.2 | 10.0 | 0.5 | 0.8 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.2 | 12.0 | 0.5 | 0.9 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M7 | 7.2 | 14.0 | 0.5 | 0.9 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wave Spring Lock Washers

|

For Screw Size | No. of Waves | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 1 | 3.2 | 8.0 | 0.5 | 1.6 | DIN 137B | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 | 1 | 3.7 | 8.0 | 0.5 | 1.8 | DIN 137B | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 1 | 4.3 | 9.0 | 0.5 | 2.0 | DIN 137B | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 3 | 4.3 | 7.1 | 0.5 | 1.5 | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 1 | 5.3 | 11.0 | 0.5 | 2.2 | DIN 137B | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 1 | 6.4 | 12.0 | 0.5 | 2.6 | DIN 137B | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 1 | 3.2 | 8.0 | 0.5 | 1.6 | DIN 137B | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 1 | 4.3 | 9.0 | 0.5 | 2.0 | DIN 137B | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 1 | 5.3 | 11.0 | 0.5 | 2.2 | DIN 137B | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 1 | 6.4 | 12.0 | 0.5 | 2.6 | DIN 137B | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 1 | 3.2 | 8.0 | 0.5 | 1.6 | DIN 137B | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 1 | 4.3 | 9.0 | 0.5 | 2.0 | DIN 137B | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 1 | 5.3 | 11.0 | 0.5 | 2.2 | DIN 137B | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 1 | 6.4 | 12.0 | 0.5 | 2.6 | DIN 137B | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Curved Spring Lock Washers

|

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 | 2.6 | 5.1 | 0.5 | 0.9 | DIN 128A | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 8.0 | 0.5 | 1.6 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 | 10.0 | 0.5 | 1.8 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 11.0 | 0.5 | 2.2 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 | 15.0 | 0.5 | 3.4 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 8.0 | 0.5 | 1.6 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 | 10.0 | 0.5 | 1.8 | DIN 137A | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 11.0 | 0.5 | 2.2 | DIN 137A | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 | 15.0 | 0.5 | 3.4 | DIN 137A | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 | 2.6 | 5.1 | 0.5 | 0.9 | DIN 128A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 8.0 | 0.5 | 1.6 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 | 10.0 | 0.5 | 1.8 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 11.0 | 0.5 | 2.2 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 | 15.0 | 0.5 | 3.4 | DIN 137A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||