Filter by

System of Measurement

Thickness

Material

Shape

End Shape

Performance

Identification Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Magnetic Properties

Minimum Hardness

Number of Slots

Sold As

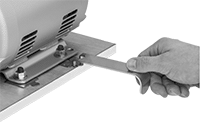

Slotted Shims

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot, mm | Each | Package | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk., mm | Thk. Tolerance, mm | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | End Shape | Each | Pkg. Qty. | Pkg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm Lg. × 50 mm Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M15 | 15.9 | 25.4 | Rockwell B70 | Labeled | Tab | 00000000 | 00000 | 10 | 00000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

75 mm Lg. × 75 mm Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M22 | 22.3 | 38.1 | Rockwell B70 | Labeled | Tab | 00000000 | 0000 | 10 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

100 mm Lg. × 100 mm Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M30 | 31.8 | 50.8 | Rockwell B70 | Labeled | Tab | 00000000 | 00000 | 10 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

125 mm Lg. × 125 mm Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M40 | 41.3 | 84.1 | Not Rated | Labeled | Tab | 00000000 | 00000 | 10 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

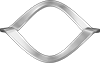

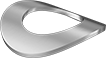

Curved Spring Lock Washers

|

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 2.7 | 5.6 | 0.7 | 1.3 | DIN 6905 | 200 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||