Filter by

System of Measurement

Thickness

Material

Shape

Performance

Identification Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Magnetic Properties

Minimum Hardness

Number of Slots

End Shape

Sold As

Slotted Shims

|

|

Tab End |

Slip these shims around existing mounting fasteners to precisely align and level components such as pumps, compressors, and gearboxes with motors, all without disassembling them. They’re also good for leveling machines on uneven surfaces. To reduce sizing errors, these shims are either labeled with their thickness so there's no need to measure or color coded by thickness to quickly spot the right size.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

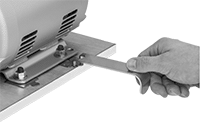

Insertion Tools—Ease shim insertion and removal, keeping your fingers clear in the process.

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk., mm | Thk. Tolerance, mm | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | End Shape | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm Lg. × 50 mm Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M15 | 15.9 | 25.4 | Rockwell B70 | Labeled | Tab | 9722K591 | 00000 | 97235K915 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

75 mm Lg. × 75 mm Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M22 | 22.3 | 38.1 | Rockwell B70 | Labeled | Tab | 9722K592 | 0000 | 97235K93 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

100 mm Lg. × 100 mm Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M30 | 31.8 | 50.8 | Rockwell B70 | Labeled | Tab | 9722K593 | 00000 | 97235K93 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

125 mm Lg. × 125 mm Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | -0.032 to 0.032 | M40 | 41.3 | 84.1 | Not Rated | Labeled | Tab | 9722K594 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

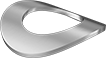

Curved Spring Lock Washers

|

The curvy, spring-like shape adds a small amount of tension to prevent nuts and screws from backing out due to mild vibration. These washers also flex slightly to compensate for uneven surfaces. While more secure than a standard flat washer, these have the least amount of gripping power of all our lock washers. They are best suited for electrical panels, light fixtures, and other light duty assemblies. These washers hold their shape when untightened, so you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Zinc-Yellow-Chromate-Plated Steel—With the same corrosion resistance as zinc-plated steel, these withstand occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Steel—Best for dry environments since moisture will cause these washers to rust.

DIN 128A—These washers have split ends that bite into your material surface for a tighter hold than other curved washers.

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 97093A141 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 97093A124 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 96982A138 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.1 | 7.6 | 0.7 | 1.2 | DIN 128A | 100 | 97093A112 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 2.7 | 5.6 | 0.7 | 1.3 | DIN 6905 | 200 | 91169A312 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

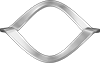

Wave Spring Lock Washers

|

The wavy shape flexes like a spring to keep nuts and screws secure on slightly uneven surfaces. These washers add a small amount of tension to stop fasteners from backing out due to mild vibration. While they don't hold as well as other lock washers, they do grip slightly better than curved washers. They work best in electrical panels, light fixtures, and other light duty assemblies. Since these washers hold their shape when untightened, you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

DIN 128B—These washers have split ends that bite into your material surface for a tighter hold than other wave washers.