Filter by

ID

Thickness

System of Measurement

Shape

Performance

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Magnetic Properties

Shaft Type

Sold As

Specifications Met

Passivation

For Bearing Nut Face Style

Width

Hardness

Shims

|

With thickness tolerances as fine as a strand of hair, these shims precisely align, space, and level components on shafts, arbors, and machinery.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Carbon Steel—Best for dry environments since moisture will cause these shims to rust.

Stress-Resistant Spring Steel—These shims are harder and hold their shape better than carbon steel. Use them for high-stress applications, such as leveling heavy machinery. They're best for dry environments since moisture will cause them to rust.

Aluminum—These shims are an alternative to stainless steel for rust resistance but aren't as hard so they may not retain their shape as well. One-third

the weight of steel, they’re commonly used in robotics and automation.

Brass—With a warm, polished look, these shims are often chosen for their appearance. Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments.

Copper—Good conductors of heat, these shims are often used when installing heat sinks. As our softest metal shims, they prevent damage to equipment and components but may not retain their shape as well as other metal shims.

Ultra-Chemical-Resistant PTFE—The most chemical-resistant shims we offer, these stand up to the widest range of harsh acids, bases, solvents, and corrosive cleaners, even at temperatures up to 500° F. They also won't mar delicate surfaces.

Thk., mm | Thk. Tolerance, mm | ID Tolerance, mm | OD Tolerance, mm | Min. Hardness | Color | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm ID × 8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 25 | 98089A101 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm ID × 10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 25 | 98089A105 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A110 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A119 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A123 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A126 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm ID × 20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A129 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A133 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm ID × 25 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A137 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A141 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22 mm ID × 30 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A144 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A148 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 10 | 98089A152 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

45 mm ID × 55 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 5 | 98089A156 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm ID × 62 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.05 to 0.05 | Rockwell B70 | — | — | 5 | 98089A159 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mm ID × 8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 100 | 3088A101 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm ID × 10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 100 | 3088A693 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 100 | 3088A103 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 100 | 3088A104 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 100 | 3088A694 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 100 | 3088A106 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm ID × 20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 50 | 3088A695 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 50 | 3088A108 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm ID × 25 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 50 | 3088A697 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 25 | 3088A11 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22 mm ID × 30 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 25 | 3088A111 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 25 | 3088A112 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 10 | 3088A113 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

35 mm ID × 45 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 10 | 3088A114 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40 mm ID × 50 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 10 | 3088A115 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm ID × 62 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 5 | 3088A116 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

55 mm ID × 68 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 5 | 3088A117 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60 mm ID × 75 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 5 | 3088A118 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

70 mm ID × 90 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 1 | 3088A2 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

80 mm ID × 100 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B40 | — | — | 1 | 3088A201 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | DIN 988 | 10 | 98055A531 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | DIN 988 | 10 | 98055A535 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm ID × 62 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | DIN 988 | 5 | 98055A539 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60 mm ID × 75 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.05 to 0 | 0.03 to 0.4 | -0.47 to -0.04 | Rockwell B85 | — | DIN 988 | 1 | 98055A541 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | 25 | 92661A935 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | 25 | 92661A936 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | 25 | 92661A937 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | 10 | 92661A938 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Brinell 60 | — | — | 10 | 92661A939 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | ASTM B36 | 10 | 92678A652 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | ASTM B36 | 10 | 92678A653 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | ASTM B36 | 10 | 92678A654 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | ASTM B36 | 5 | 92678A656 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30 mm ID × 42 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell B14 | — | ASTM B36 | 1 | 92678A658 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | ASTM B152 | 10 | 94397A789 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm ID × 14 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | ASTM B152 | 10 | 94397A791 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm ID × 16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | ASTM B152 | 10 | 94397A792 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | ASTM B152 | 10 | 94397A793 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm ID × 22 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | ASTM B152 | 10 | 94397A794 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | Rockwell F40 | — | ASTM B152 | 5 | 94397A795 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Chemical-Resistant PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm ID × 12 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | 25 | 90334A223 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm ID × 18 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | 25 | 90334A224 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm ID × 28 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | 5 | 90334A225 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25 mm ID × 36 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.14 to 0.14 | -0.3 to 0.3 | -0.5 to 0.5 | — | White | — | 5 | 90334A226 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

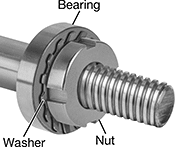

Bearing Spring Lock Washers for Slotted Bearing Nuts

|  |

For Chamfered Nuts |

Designed for use with bearing nuts, these lock washers have a conical shape that presses like a spring against bearings, bushings, gears, and pulleys to hold them in place on your threaded shaft or spindle. They also have an inner tab that sits in the shaft or spindle’s keyway to prevent the nut from loosening.

Steel—Steel washers are strong and flexible.

External Tooth—Washers with external teeth grip components using their teeth, in addition to spring tension.

DIN 5406—DIN 462 and DIN 5406 washers meet international standards for lock washer dimensions. Pair DIN 462 washers with DIN 1804 bearing nuts, and DIN 5406 washers with DIN 981 bearing nuts.

Tab, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Wd. | Dp. | Overall Ht., mm | Tooth Location | Hardness | Specs. Met | For Bearing Nut Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Chamfered Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 | 60.000 | 86.000 | 1.500 | 8.000 | 2.500 | 4.500 | External | Not Rated | DIN 5406 | DIN 981 | 90391A124 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 | 65.000 | 92.000 | 1.500 | 8.000 | 2.500 | 4.500 | External | Not Rated | DIN 5406 | DIN 981 | 90391A125 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M70 | 70.000 | 98.000 | 1.500 | 8.000 | 3.500 | 4.500 | External | Not Rated | DIN 5406 | DIN 981 | 90391A126 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M75 | 75.000 | 104.000 | 1.500 | 8.000 | 3.500 | 5.000 | External | Not Rated | DIN 5406 | DIN 981 | 90391A127 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

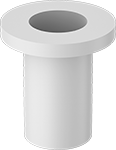

Insulating Sleeve Washers

Cover screw threads to stop electrical current in its tracks and prevent short circuits. These washers create a barrier between the screw threads and the mating surface when mounted in through holes. This barrier also extends the life of your assembly by preventing galvanic corrosion, which is when two different metals rust more quickly due to contact with each other.

Flat Edge

|

The flat edge distributes weight evenly to take pressure off screw heads.

Nylon—Our most versatile insulating washers, these block unwanted current in everything from switches and circuit breakers to control panels and electric motors.

Very-High-Temperature Ceramic—Our most heat-resistant washers and the best electrical insulators. These won't melt or become brittle at blistering temperatures up to 1,700° F, making them perfect for ovens, kilns, and furnaces. Ceramic may crack or dent if subjected to hard bumps, however, so these washers are not recommended for high-vibration applications.

Sleeve, mm | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | Ht. | OD | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Min. | Max. | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 3.000 | 6.000 | 4.100 | 8.400 | 1.500 | 4.500 | -40 | 180 | Off-White | 100 | 91145A316 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 5.000 | 6.000 | 4.100 | 8.400 | 1.500 | 6.500 | -40 | 180 | Off-White | 100 | 91145A315 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Very-High-Temperature Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.500 | 3.000 | 2.100 | 4.200 | 1.500 | 4.000 | Not Rated | 1,700 | Off-White | 1 | 92107A111 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 1.500 | 4.000 | 3.100 | 6.200 | 1.500 | 3.000 | Not Rated | 1,700 | Off-White | 1 | 92107A112 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.500 | 4.000 | 3.100 | 6.200 | 1.500 | 5.000 | Not Rated | 1,700 | Off-White | 1 | 92107A113 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 7.500 | 4.000 | 3.100 | 6.200 | 1.500 | 9.000 | Not Rated | 1,700 | Off-White | 1 | 92107A114 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 3.000 | 6.000 | 4.100 | 8.400 | 1.500 | 4.500 | Not Rated | 1,700 | Off-White | 1 | 92107A115 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 5.000 | 6.000 | 4.100 | 8.400 | 1.500 | 6.500 | Not Rated | 1,700 | Off-White | 1 | 92107A116 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Leveling Washers for I-Beams

Mounted on an I-Beam |

|

Commonly called beveled washers, these are tapered to fit inside an I-beam's flange to provide a parallel bearing surface.

18-8 Stainless Steel—18-8 stainless steel washers have good chemical resistance and may be mildly magnetic. These washers are the most corrosion-resistant option.

Zinc-Plated Steel—Zinc-plated steel washers are coated for corrosion resistance in wet environments.

Galvanized Steel—Galvanized steel washers are ten times more corrosion resistant than zinc-plated washers.

Thk., mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | Wd., mm | (A) | (B) | Hardness | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 1 | 91146A170 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 1 | 91146A180 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 10 | 91146A100 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 10 | 91146A110 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 10 | 91146A240 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 5 | 91146A250 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

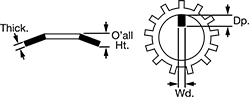

Heavy-Vibration-Resistant Spring Lock Washers

|

With a grip that's second only to wedge lock, these washers stop nuts and screws from wiggling loose under constant, vigorous vibration. They are ideal for engines, turbines, generators, and other heavy duty equipment. Similar to a spring, they flatten under pressure to add tension between mating surfaces. As long as the washers aren't deformed or otherwise damaged, you can reuse them indefinitely without losing locking strength. Also known as conical washers and Belleville washers.

Stack multiple washers in the same direction to double or triple how much weight they can bear. Stack washers in opposite directions for better deflection, which means they compress further and withstand more shock and movement without loosening.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Black-Oxide 18-8 Stainless Steel—Typically chosen for their appearance, these washers have a dark, matte coating to create a finished look. They won't rust in wet and outdoor environments, but can't hold up to harsh chemicals as well as 316 stainless steel.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Phosphate-Coated Steel—Paint adheres evenly to the surface of these washers, so you can add your own decorative finish. They are more durable than zinc-plated steel washers to withstand wet and outdoor environments. However, they won't hold up to the harsh chemicals that stainless steel can.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 14.0 | 1.5 | 2.0 | DIN 6796 | 25 | 91477A161 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.2 | 20.7 | 1.5 | 2.3 | — | 10 | 91235A411 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 14.0 | 1.5 | 2.0 | DIN 6796 | 5 | 92471A110 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 14.0 | 1.5 | 2.0 | DIN 6796 | 10 | 93237A105 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 14.0 | 1.5 | 2.0 | DIN 6796 | 25 | 95221A109 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.3 | 20.5 | 1.5 | 2.6 | — | 10 | 90127A129 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 14.0 | 1.5 | 2.0 | DIN 6796 | 50 | 95221A204 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 14.0 | 1.5 | 2.0 | DIN 6796 | 50 | 93497A161 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Bonded Sealing Washers

|

Eliminate nooks and crannies under the nut or screw head where dirt and bacteria could collect. Unlike other bonded washers, the metal ring nests inside the rubber layer, creating a smooth outer surface that's easy to clean. These washers stand up to harsh cleaners and detergents and won't corrode from frequent washdowns. They're commonly found on equipment in food and pharmaceutical processing plants to prevent leaks and block out contaminants. Reuse them a handful of times, as long as the material isn't damaged.

316 Stainless Steel and EPDM—These washers are highly resistant to tearing, scuffs, and scrapes. They are more economical than Fluoroprene Fluoroelastomer, however, they aren't as heat resistant.

Chemical-Resistant 316 Stainless Steel and Fluoroprene Fluoroelastomer—These washers withstand higher temperatures than EPDM, so you can sterilize them with steam. They also resist more chemicals, such as oil, solvents, and acids.

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Min. | Max. | Color | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel and EPDM | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.100 | 21.200 | 1.500 | -40 | 300 | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600, NSF/ANSI 51 | 90443A150 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 12.100 | 25.500 | 1.500 | -40 | 300 | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600, NSF/ANSI 51 | 90443A160 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 16.100 | 33.900 | 1.500 | -40 | 300 | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600, NSF/ANSI 51 | 90443A170 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant 316 Stainless Steel and Fluoroprene Fluoroelastomer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.100 | 21.200 | 1.500 | 5 | 390 | Blue | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 90443A230 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 12.100 | 25.500 | 1.500 | 5 | 390 | Blue | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 90443A240 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 16.100 | 33.900 | 1.500 | 5 | 390 | Blue | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 90443A250 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Curved Spring Lock Washers

|

The curvy, spring-like shape adds a small amount of tension to prevent nuts and screws from backing out due to mild vibration. These washers also flex slightly to compensate for uneven surfaces. While more secure than a standard flat washer, these have the least amount of gripping power of all our lock washers. They are best suited for electrical panels, light fixtures, and other light duty assemblies. These washers hold their shape when untightened, so you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Zinc-Yellow-Chromate-Plated Steel—With the same corrosion resistance as zinc-plated steel, these withstand occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

DIN 128A—These washers have split ends that bite into your material surface for a tighter hold than other curved washers.

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.1 | 14.8 | 1.5 | 2.5 | DIN 128A | 50 | 97093A144 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.1 | 14.8 | 1.5 | 2.5 | DIN 128A | 100 | 97093A127 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.1 | 14.8 | 1.5 | 2.5 | DIN 128A | 100 | 96982A142 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.1 | 14.8 | 1.5 | 2.5 | DIN 128A | 50 | 97093A115 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wave Spring Lock Washers

|

The wavy shape flexes like a spring to keep nuts and screws secure on slightly uneven surfaces. These washers add a small amount of tension to stop fasteners from backing out due to mild vibration. While they don't hold as well as other lock washers, they do grip slightly better than curved washers. They work best in electrical panels, light fixtures, and other light duty assemblies. Since these washers hold their shape when untightened, you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

DIN 128B—These washers have split ends that bite into your material surface for a tighter hold than other wave washers.