Filter by

Thread Size

OD

Export Control Classification Number (ECCN)

ID

Shaft Diameter

Weight Capacity

Jaw Control Type

DFARS Specialty Metals

Puller Jaw Type

Performance

Slide Pin Extractors

Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw Style | For Pin Diameter | Overall Lg. | Handle | Grip | Flexibility | Puller Material | Handle Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

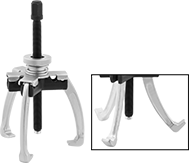

3 Jaws | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chuck, External | 1/16" to 33/64" (1 mm to 13 mm) | 15" | Straight | Plain | Rigid | Steel | Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

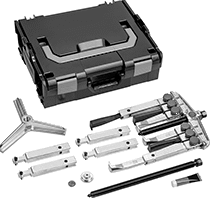

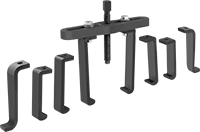

Reversible-Jaw External/Internal-Grip Gear and Bearing Puller Sets with Locking Storage Box

Wt. Cap., ton | Puller Material | Includes | Each | |||

|---|---|---|---|---|---|---|

| 5 1/2 to 7 1/2 | Steel | Internal Extractor (for 1/2"-1-7/8" ID, 1-1/2" Reach) Six Cap Screws (3 of each: 3/8"-24 × 3" Lg., 3/8"-16 × 3" Lg.) for Adjustable Face-Grip Puller Steel Locking Cabinet (25 3/4" Height, 29 1/2" Width, 10" Depth) 2/3 Reversible-Jaw External/Internal Grip Puller (For 1 1/4"-6 3/4" ID, For 1/4"-6" OD, 4-3/4" Reach) with Slide Hammer Adjustable Face-Grip Puller (For 3 1/4"-9 5/8" OD) with 6 3/4” Long Forcing Screw Adjustable Face-Grip Puller (For 3/4"-4 1/4" OD) with 4 1/4” Long Forcing Screw Combination 2/3-Jaw External Grip Puller—7 1/2-ton Capacity (For Up To 10 1/2" OD, 5" Reach) Combination 2/3-Jaw External Grip Puller—5 1/2-ton Capacity (For Up To 7" OD, 3 1/4" Reach) Two Sets of Long-Reach Jaws (Three Jaws for 5 1/2-ton Capacity Puller and Three Jaws for 7-ton Capacity Puller) Bearing Separator (1/4"-1 3/4 Spread) Bearing Separator (3/4"-4 1/4" Spread) | 00000000 | 000000000 | ||

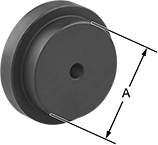

Thread Adapters for Pullers

|

Gender | |||||||

|---|---|---|---|---|---|---|---|

Thread Size (A) | Thread Size (B) | (A) | (B) | Each | |||

| 5/8"-18 | 1/4"-20 | Female | Male | 000000 | 000000 | ||

| 5/8"-18 | 5/16"-18 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 3/8"-16 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 3/8"-24 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 7/16"-14 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 1/2"-13 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 1/2"-20 | Female | Male | 000000 | 00000 | ||

| 1"-14 | 5/8"-18 | Female | Male | 000000 | 00000 | ||

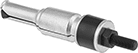

Expanding-Collar Internal-Grip Gear and Bearing Pullers

Pin and Pin Adapter Required

Pullers | Pins | Pin Adapter | |||||||

|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Puller Material | For Pin Dia. | Each | Each | Each | ||||

| 5/16" to 11/32" | Steel | 5/32" | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | |

| 11/32" to 7/16" | Steel | 3/16" | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |

| 7/16" to 9/16" | Steel | 9/32" | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |

| 9/16" to 7/8" | Steel | 13/32" | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |

Ready to Use

|

For Shaft Dia. | Thread Size | Puller Material | Each | ||

|---|---|---|---|---|---|

| 1/4" to 3/8" | M7 | Steel | 0000000 | 0000000 | |

| 3/8" to 1/2" | M7 | Steel | 0000000 | 000000 | |

| 1/2" to 5/8" | M7 | Steel | 0000000 | 000000 | |

| 5/8" to 3/4" | M7 | Steel | 0000000 | 000000 | |

| 3/4" to 7/8" | M10 | Steel | 0000000 | 000000 | |

| 3/4" to 1 3/16" | M10 | Steel | 0000000 | 000000 | |

| 1 3/16" to 1 5/8" | M10 | Steel | 0000000 | 000000 | |

| 1 3/8" to 1 7/8" | M15 | Steel | 0000000 | 000000 | |

| 1 3/4" to 2 1/4" | M15 | Steel | 0000000 | 000000 | |

| 2 1/4" to 4 3/8" | 1/2"-14 | Steel | 0000000 | 000000 | |

| 3 7/8" to 7 7/8" | 3/4"-14 | Steel | 0000000 | 000000 |

Reversible-Jaw External/Internal-Grip Gear and Bearing Pullers

Combination 2/3 Jaws with Tips on One End

For ID | For OD | Reach Lg. | Wt. Cap. | Puller Material | T-Handle Material | Includes | Each | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/4" to 4 1/4" | 1" to 4 1/2" | 1 1/4", 3" | Not Rated | Steel | Steel | T-Handle | 000000 | 0000000 | ||

Internal-Grip Gear and Bearing Pullers

Two Jaws with Tips on One End

For ID | Reach Lg. | Wt. Cap. | Puller Material | Jaw Overall Lg. | Jaw Tip Wd. × Jaw Tip Thk. | Each | |||

|---|---|---|---|---|---|---|---|---|---|

| 1/2" to 1 1/2" | 3/4" | Not Rated | Steel | 4 1/4" | 7/16" × 1/8" | 000000 | 0000000 | ||

Expanding-Collar Internal-Grip Gear and Bearing Puller Sets

Ready to Use

For Shaft Dia. | Puller Material | Includes | Each | ||

|---|---|---|---|---|---|

| 3/16" to 2 3/4" | Steel | Eight Pullers with Nut Two Bridges with T-Handle Forcing Screw (1 of Each: 4 1/2" Reach and 2 3/16" Width, 6 1/2" Reach and 3 7/8" Width) Grease | 00000000 | 000000000 | |

| 1/4" to 1 3/16" | Steel | Four Pullers with Nut 1 lb. Slide Hammer (M12 Thread Size) Handle for Slide Hammer Bridge with T-Handle Forcing Screw (4 1/2" Reach, 2 3/16" Width) Grease | 00000000 | 000000 | |

| 1 1/8" to 2 3/4" | Steel | Four Pullers with Nut 2 lb. Slide Hammer (M12 Thread Size) Handle for Slide Hammer Bridge with T-Handle Forcing Screw (6 1/2" Reach, 3 7/8" Width) Grease | 00000000 | 000000 | |

| 2 3/8" to 6 1/8" | Steel | Grease Puller Bridge with T-Handle Forcing Screw (9 3/8" Reach, 9 7/8" Width) | 00000000 | 00000000 |

Quick-Hold Reversible-Jaw External/Internal-Grip Gear and Bearing Pullers

Two Jaws with Tips on One End

|  |

Standard Jaw—Bar Control | Narrow Jaw—Bar Control |

Forcing Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For ID | For OD | Reach Lg. | Wt. Cap., ton | Puller Material | Material | Overall Lg. | Thread Size | Jaw Overall Lg. | Jaw Tip Wd. × Jaw Tip Thk. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Jaw—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" to 6 1/4" | 1/2" to 5" | 3 7/8" | 5 | Steel | Steel | 7 1/4" | M14 × 1.5 mm | 4" | 13/16" × 1/8" | Forcing Screw | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 4 3/4" | 1/4" to 3 1/2" | 3 7/8" | 5 | Steel | Steel | 7 1/4" | M14 × 1.5 mm | 4" | 13/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 8 3/4" | 1/2" to 6 1/4" | 5 7/8" | 10 | Steel | Steel | 10" | 1/2"-14 | 6" | 15/16" × 3/16" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 10 1/4" | 1/2" to 7 3/4" | 5 7/8" | 10 | Steel | Steel | 10" | 1/2"-14 | 6" | 15/16" × 3/16" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 13 1/2" | 0" to 9 3/4" | 7 7/8" | 12 | Steel | Steel | 13 1/4" | 3/4"-14 | 7 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 17 1/4" | 0" to 13 3/4" | 7 7/8" | 12 | Steel | Steel | 13 1/4" | 3/4"-14 | 7 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 3/4" to 23 1/4" | 1/2" to 20 1/2" | 11 7/8" | 15 | Steel | Steel | 17 3/4" | 1"-11 | 11 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Narrow Jaw—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" to 5 1/2" | 1/4" to 3 1/2" | 3 7/8" | 4 1/2 | Steel | Steel | 7 1/4" | M14 × 1.5 mm | 4" | 1 3/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" to 7" | 1/4" to 4 3/4" | 3 7/8" | 4 1/2 | Steel | Steel | 7 1/4" | M14 × 1.5 mm | 4" | 1 3/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 8 3/4" | 3/4" to 6 1/4" | 5 7/8" | 9 1/2 | Steel | Steel | 10" | 1/2"-14 | 6" | 1 1/4" × 5/32" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 10 1/4" | 3/4" to 7 3/4" | 5 7/8" | 9 1/2 | Steel | Steel | 10" | 1/2"-14 | 6" | 1 1/4" × 5/32" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 13 1/2" | 3/4" to 9 3/4" | 7 7/8" | 11 1/2 | Steel | Steel | 13 1/4" | 3/4"-14 | 7 3/4" | 1 3/8" × 1/4" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 17 1/4" | 3/4" to 13 3/4" | 7 7/8" | 11 1/2 | Steel | Steel | 13 1/4" | 3/4"-14 | 7 3/4" | 1 3/8" × 1/4" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Jaws with Tips on One End

|  |

Standard Jaw—Bar Control | Narrow Jaw—Bar Control |

Forcing Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For ID | For OD | Reach Lg. | Wt. Cap., ton | Puller Material | Material | Overall Lg. | Thread Size | Jaw Overall Lg. | Jaw Tip Wd. × Jaw Tip Thk. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Jaw—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" to 5 1/2" | 0" to 3 1/2" | 3 7/8" | 6 1/2 | Steel | Steel | 6 1/4" | M14 × 1.5 mm | 4" | 13/16" × 1/8" | Forcing Screw | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" to 7" | 0" to 5" | 3 7/8" | 6 1/2 | Steel | Steel | 6 1/4" | M14 × 1.5 mm | 4" | 13/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 8 3/4" | 0" to 6 1/4" | 5 7/8" | 11 1/2 | Steel | Steel | 10" | 1/2"-14 | 6" | 15/16" × 3/16" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 10 1/4" | 0" to 7 3/4" | 5 7/8" | 11 1/2 | Steel | Steel | 10" | 1/2"-14 | 6" | 15/16" × 3/16" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 13 1/2" | 0" to 9 3/4" | 7 7/8" | 13 1/2 | Steel | Steel | 13 1/4" | 3/4"-14 | 7 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 17 1/4" | 4 1/4" to 14 3/4" | 7 7/8" | 13 1/2 | Steel | Steel | 17 3/4" | 1"-11 | 7 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 3/4" to 19 3/4" | 4 1/4" to 14 3/4" | 11 7/8" | 16 1/2 | Steel | Steel | 17 3/4" | 1"-11 | 11 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 3/4" to 19 3/4" | 4 1/4" to 14 3/4" | 19 3/4" | 16 1/2 | Steel | Steel | 17 3/4" | 1"-11 | 19 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" to 23 1/2" | 5" to 20 1/2" | 19 3/4" | 22 | Steel | Steel | 16 3/8" | 1 1/8"-11 | 19 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 1/2" to 29 1/4" | 6" to 25 1/2" | 19 3/4" | 22 | Steel | Steel | 16 3/8" | 1 1/8"-11 | 19 3/4" | 1 3/8" × 5/32" | Forcing Screw | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Narrow Jaw—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" to 5 1/2" | 1/4" to 3 1/2" | 3 7/8" | 6 | Steel | Steel | 6 1/4" | M14 × 1.5 mm | 4" | 1 3/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" to 7" | 1/4" to 5" | 3 7/8" | 6 | Steel | Steel | 6 1/4" | M14 × 1.5 mm | 4" | 1 3/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 8 3/4" | 3/4" to 6 1/4" | 5 7/8" | 11 | Steel | Steel | 10" | 1/2"-14 | 6" | 1 3/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" to 10 1/4" | 3/4" to 7 3/4" | 5 7/8" | 11 | Steel | Steel | 10" | 1/2"-14 | 6" | 1 3/16" × 1/8" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" to 13 1/2" | 0" to 9 3/4" | 7 7/8" | 13 | Steel | Steel | 13 1/4" | 3/4"-14 | 7 3/4" | 1 3/8" × 1/4" | Forcing Screw | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Combination 2/3 Jaws with Tips on One End

Pullers | Replacement Forcing Screws | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Forcing Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For ID | For OD | Reach Lg. | Wt. Cap., ton | Puller Material | Material | Overall Lg. | Thread Size | Jaw Overall Lg. | Jaw Tip Wd. × Jaw Tip Thk. | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Jaw—Spring-Loaded Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" to 4" | 3" to 4" | 4" | 2 | Steel | Steel | 8 3/4" | M15 × 2 mm | 4" | 9/16" × 3/16" | Forcing Screw | 0000000 | 0000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" to 7" | 3" to 7" | 7" | 5 | Steel | Steel | 11 3/4" | M18 × 2.5 mm | 7" | 7/8" × 1/4" | Forcing Screw | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reversible-Jaw External/Internal-Grip Gear and Bearing Puller Sets

|  |

Two Jaws—Bar Control | Two Jaws and Combination 2/3 Jaws |

| |

4 Two Jaws and 2 Combination 2/3 Jaws |

Wt. Cap., ton | Puller Material | Forcing Screw Material | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Two Jaws—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | Steel | Steel | Crossbar Forcing Screw (7/8"-9" Thread Size, 8" Long) Four Sets of Jaws (5", 6", 6" Tapered Tip, and 8" Reach) Two Jaw-Mounting Screws | 000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Jaws and Combination 2/3 Jaws | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not Rated | Steel | — | Slide Hammer Puller with Grip Handle Clamping Cone Puller Hook 2-Jaw Jaw Bar 4 Sets of 2/3 Reversible-Jaw External/Internal Jaws (For 1"-8" ID, For 1/4"-6 3/4" OD, 4 3/4"-6 1/2" Reach) | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | Steel | — | 2-Reversible-Jaw External/Internal Grip Puller —5-ton Capacity (For 5/8"-6" OD) 2/3-Jaw External Grip Puller—10-ton Capacity (For Up To 16" OD, 11" Reach) 2-Reversible-Jaw External/Internal Grip Puller —7-ton Capacity (For 1/2"-8 5/8" OD) Internal Extractor (for 1/2"-1-7/8" ID, 1-1/2" Reach) Six Cap Screws (3 of each: 3/8"-24 × 3" Lg., 3/8"-16 × 3" Lg.) for Adjustable Face-Grip Puller 2/3 Reversible-Jaw External/Internal Grip Puller (For 1 1/4"-6 3/4" ID, For 1/4"-6" OD, 4-3/4" Reach) with Slide Hammer Adjustable Face-Grip Puller (For 3 1/4"-9 5/8" OD) with 6 3/4” Long Forcing Screw Adjustable Face-Grip Puller (For 3/4"-4 1/4" OD) with 4 1/4” Long Forcing Screw Bearing Separator (1/4"-1 3/4 Spread) Bearing Separator (3/4"-4 1/4" Spread) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

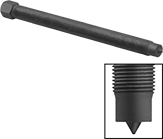

Gear and Bearing Puller Forcing Screws

|

Thread Size | Lg. | Material | Fastener Head Style | Each | ||

|---|---|---|---|---|---|---|

| 5/16"-24 | 4 1/8" | Steel | T-Handle | 000000 | 000000 | |

| 5/16"-24 | 5 3/8" | Steel | T-Handle | 00000000 | 00000 | |

| 3/8"-24 | 6 7/8" | Steel | T-Handle | 00000000 | 00000 | |

| 1/2"-20 | 9" | Steel | Hex | 00000000 | 0000 | |

| 9/16"-16 | 10 1/8" | Steel | Hex | 00000000 | 00000 | |

| 9/16"-20 | 6 7/8" | Steel | Hex | 0000000 | 00000 | |

| 5/8"-14 | 12 7/8" | Steel | Hex | 00000000 | 00000 | |

| 5/8"-18 | 5 1/2" | Steel | Hex | 0000000 | 00000 | |

| 5/8"-18 | 13" | Steel | Hex | 0000000 | 00000 | |

| 11/16"-18 | 9" | Steel | Hex | 0000000 | 00000 | |

| 3/4"-14 | 16 5/8" | Steel | Hex | 00000000 | 000000 | |

| 3/4"-14 | 19 5/8" | Steel | Hex | 00000000 | 000000 | |

| 7/8"-9 | 8" | Steel | Square | 0000000 | 000000 | |

| 1"-14 | 13 3/4" | Steel | Hex | 0000000 | 000000 | |

| 1 1/8"-14 | 26 3/8" | Steel | Hex | 00000000 | 000000 | |

| 1 1/4"-12 | 16" | Steel | Hex | 0000000 | 000000 | |

| 1 1/4"-14 | 32" | Steel | Hex | 00000000 | 000000 | |

| 1 1/2"-6 | 14" | Steel | Hex | 0000000 | 000000 |

Quick-Hold Reversible-Jaw External/Internal-Grip Gear and Bearing Puller Sets

Forcing Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., ton | Puller Material | Material | Thread Size | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Narrow Jaw—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Jaws and Combination 2/3 Jaws with Tips on One End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2 | Steel | Steel | M14 × 1.5 mm | Quick-Hold 2-Jaw Reversible External/Internal Grip Puller Three Sets of Narrow-Profile Jaws (For 2 3/4"-7 1/8" ID, For 1 1/16"-5 1/8" OD, 3 15/16"-9 13/16" Reach) Set of Jaw Extensions (3 15/16" Long) Forcing Screws (1 of each: 6 5/16" Long, 9 13/16" Long) 2-to-3 Jaw Converter Grease Plastic case | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard and Narrow Jaw—Bar Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Jaws and Combination 2/3 Jaws with Tips on One End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/2 | Steel | Steel | 1/2"-14 | Quick-Hold 2-Jaw Reversible External/Internal Grip Puller One Set of Narrow-Profile Jaws (For 3 7/8"-10 1/4" ID, For 1 3/8"-7 7/8" OD, 5 15/16"-11 13/16" Reach) One Set of Standard-Profile Jaws (For 3 7/8"-10 1/4" ID, For 1 3/8"-7 7/8" OD, 5 15/16"-11 13/16" Reach) Two Sets of Jaw Extensions (5 15/16" Long) Forcing Screws (1 of each: 8 5/16" Long, 14" Long) 2-to-3 Jaw Converter Grease Plastic case | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||