Filter by

Hammer Type

Thread Size

Pin Diameter

Material

Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Locking Plier Length

Performance

Puller Jaw Type

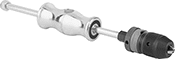

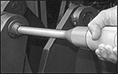

Slide Pin Extractors

Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw Style | For Pin Diameter | Overall Lg. | Handle | Grip | Flexibility | Puller Material | Handle Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Jaws | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chuck, External | 1/16" to 33/64" (1 mm to 13 mm) | 15" | Straight | Plain | Rigid | Steel | Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

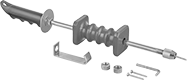

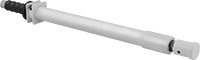

Dent Pullers

Overall Lg. | Shaft Thread Size | Includes | Each | ||

|---|---|---|---|---|---|

| 22" | 1/2"-20 | Nosepiece, L-Shaped Puller with Two Screws, Door Edge Tool with Two Nuts | 0000000 | 000000 |

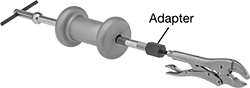

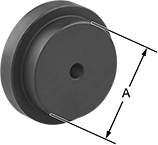

Thread Adapters for Pullers

|

Gender | |||||||

|---|---|---|---|---|---|---|---|

Thread Size (A) | Thread Size (B) | (A) | (B) | Each | |||

| 5/8"-18 | 1/4"-20 | Female | Male | 000000 | 000000 | ||

| 5/8"-18 | 5/16"-18 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 3/8"-16 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 3/8"-24 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 7/16"-14 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 1/2"-13 | Female | Male | 000000 | 00000 | ||

| 5/8"-18 | 1/2"-20 | Female | Male | 000000 | 00000 | ||

| 1"-14 | 5/8"-18 | Female | Male | 000000 | 00000 | ||

Reversible-Jaw External/Internal-Grip Gear and Bearing Pullers

Combination 2/3 Jaws with Tips on One End

For ID | For OD | Reach Lg. | Wt. Cap. | Puller Material | T-Handle Material | Includes | Each | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/4" to 4 1/4" | 1" to 4 1/2" | 1 1/4", 3" | Not Rated | Steel | Steel | T-Handle | 000000 | 0000000 | ||

Pull-Out Dowel Pins

Steel

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Dia. Tolerance | Thread Size | Double Shear Breaking Strength, lbf | Min. Hardness | Specs. Met | 1-49 | 50-199 | 200-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.0001" to 0.0003" | 5/16"-18 | 57,000 | Rockwell C47 | ASME B18.8.2 | 000000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

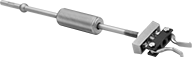

Slide Hammer Adapters for Locking Pliers

Internal-Grip Gear and Bearing Pullers

Two Jaws with Tips on One End

For ID | Reach Lg. | Wt. Cap. | Puller Material | Jaw Overall Lg. | Jaw Tip Wd. × Jaw Tip Thk. | Each | |||

|---|---|---|---|---|---|---|---|---|---|

| 1/2" to 1 1/2" | 3/4" | Not Rated | Steel | 4 1/4" | 7/16" × 1/8" | 000000 | 0000000 | ||

Slide Sledge Hammers

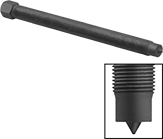

Gear and Bearing Puller Forcing Screws

|

Thread Size | Lg. | Material | Fastener Head Style | Each | ||

|---|---|---|---|---|---|---|

| 5/16"-24 | 4 1/8" | Steel | T-Handle | 000000 | 000000 | |

| 5/16"-24 | 5 3/8" | Steel | T-Handle | 00000000 | 00000 | |

| 3/8"-24 | 6 7/8" | Steel | T-Handle | 00000000 | 00000 | |

| 1/2"-20 | 9" | Steel | Hex | 00000000 | 0000 | |

| 9/16"-16 | 10 1/8" | Steel | Hex | 00000000 | 00000 | |

| 9/16"-20 | 6 7/8" | Steel | Hex | 0000000 | 00000 | |

| 5/8"-14 | 12 7/8" | Steel | Hex | 00000000 | 00000 | |

| 5/8"-18 | 5 1/2" | Steel | Hex | 0000000 | 00000 | |

| 5/8"-18 | 13" | Steel | Hex | 0000000 | 00000 | |

| 11/16"-18 | 9" | Steel | Hex | 0000000 | 00000 | |

| 3/4"-14 | 16 5/8" | Steel | Hex | 00000000 | 000000 | |

| 3/4"-14 | 19 5/8" | Steel | Hex | 00000000 | 000000 | |

| 7/8"-9 | 8" | Steel | Hex | 0000000 | 000000 | |

| 1"-14 | 13 3/4" | Steel | Hex | 0000000 | 000000 | |

| 1 1/8"-14 | 26 3/8" | Steel | Hex | 00000000 | 000000 | |

| 1 1/4"-12 | 16" | Steel | Hex | 0000000 | 000000 | |

| 1 1/4"-14 | 32" | Steel | Hex | 00000000 | 000000 | |

| 1 1/2"-6 | 14" | Steel | Hex | 0000000 | 000000 |