Filter by

Material

Thickness

Finish

Fastener Strength Grade/Class

DFARS Specialty Metals

Specifications Met

Serration Location

REACH

Export Control Classification Number (ECCN)

Color

Washer Designation

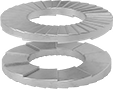

Extreme-Vibration-Resistant Wedge Lock Washers

When it's critical to keep bolted assemblies secure, choose these two-piece lock washers with the tightest grip of all. They stop nuts and screws from loosening in heavy machinery that experiences jarring starts and stops, such as compressors and compactors. Serrations on the outside bite into the fastener and mating surfaces, while wedges on the inside lock the two pieces together. When the nut or screw starts to loosen, the wedges drive more tightly together to maintain tension. You can reuse these washers up to fifteen times, as long as the serrations and wedges are not worn down. They are comparable to NORD-LOCK® or Sherex TEC® washers.

Wedge Lock

|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

Black Super-Corrosion-Resistant Zinc-Flake-Coated Steel—Typically chosen for their appearance, these washers have a dark, matte coating to create a finished look. With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. Similar to Magni-coated washers.

For Screw Size | ID | OD | Thk. | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 5, M3 | 0.130" | 0.280" | 0.060" to 0.080" | 20 | 91074A112 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6, M3.5 | 0.150" | 0.300" | 0.060" to 0.080" | 20 | 91074A102 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6, M3.5 | 0.150" | 0.350" | 0.060" to 0.080" | 20 | 91074A142 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8, M4 | 0.170" | 0.300" | 0.060" to 0.080" | 20 | 91074A115 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8, M4 | 0.170" | 0.350" | 0.060" to 0.080" | 20 | 91074A312 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10, M5 | 0.210" | 0.350" | 0.060" to 0.080" | 20 | 91074A127 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10, M5 | 0.210" | 0.430" | 0.060" to 0.080" | 20 | 91074A327 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.280" | 0.450" | 0.090" to 0.110" | 20 | 91074A129 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.280" | 0.530" | 0.090" to 0.110" | 20 | 91074A329 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16", M8 | 0.340" | 0.530" | 0.090" to 0.110" | 20 | 91074A130 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16", M8 | 0.340" | 0.650" | 0.090" to 0.110" | 20 | 91074A330 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.410" | 0.650" | 0.090" to 0.110" | 20 | 91074A131 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.410" | 0.830" | 0.090" to 0.110" | 10 | 91074A331 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16", M11 | 0.450" | 0.730" | 0.090" to 0.110" | 10 | 91074A132 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.530" | 0.770" | 0.090" to 0.110" | 10 | 91074A133 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.530" | 1.000" | 0.120" to 0.140" | 8 | 91074A333 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16", M14 | 0.600" | 0.910" | 0.120" to 0.140" | 10 | 91074A134 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16", M14 | 0.600" | 1.210" | 0.120" to 0.140" | 4 | 91074A305 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8", M16 | 0.670" | 1.000" | 0.120" to 0.140" | 8 | 91074A135 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8", M16 | 0.670" | 1.210" | 0.120" to 0.140" | 4 | 91074A335 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.790" | 1.210" | 0.120" to 0.140" | 4 | 91074A136 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.790" | 1.540" | 0.120" to 0.140" | 2 | 91074A336 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8", M22 | 0.920" | 1.360" | 0.120" to 0.140" | 2 | 91074A137 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8", M22 | 0.920" | 1.650" | 0.170" to 0.190" | 2 | 91074A337 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.100" | 1.540" | 0.120" to 0.140" | 2 | 91074A138 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.100" | 1.910" | 0.170" to 0.190" | 1 | 91074A338 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8", M30 | 1.240" | 1.850" | 0.220" to 0.240" | 1 | 91074A140 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8", M30 | 1.240" | 2.300" | 0.250" to 0.270" | 1 | 91074A360 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4", M33 | 1.350" | 1.910" | 0.220" to 0.240" | 1 | 91074A145 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8", M36 | 1.470" | 2.170" | 0.250" to 0.270" | 1 | 91074A150 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2", M39 | 1.590" | 2.300" | 0.250" to 0.270" | 1 | 91074A160 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4", M45 | 1.820" | 2.760" | 0.270" to 0.290" | 1 | 91074A367 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8", M48 | 1.950" | 2.950" | 0.270" to 0.290" | 1 | 91074A370 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2", M52 | 2.110" | 3.150" | 0.270" to 0.290" | 1 | 91074A371 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4", M56 | 2.330" | 3.350" | 0.270" to 0.290" | 1 | 91074A374 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2", M64 | 2.640" | 3.740" | 0.270" to 0.290" | 1 | 91074A378 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 0.260" | 0.430" | 0.060" to 0.080" | 20 | 91074A151 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 0.260" | 0.530" | 0.090" to 0.110" | 20 | 91074A169 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 0.420" | 0.650" | 0.090" to 0.110" | 20 | 91074A180 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 0.420" | 0.830" | 0.090" to 0.110" | 10 | 91074A211 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 0.510" | 0.770" | 0.090" to 0.110" | 10 | 91074A221 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 0.510" | 1.000" | 0.120" to 0.140" | 8 | 91074A289 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 | 0.770" | 1.140" | 0.120" to 0.140" | 4 | 91074A308 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 | 0.770" | 1.360" | 0.120" to 0.140" | 2 | 91074A314 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 0.840" | 1.210" | 0.120" to 0.140" | 4 | 91074A325 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 0.840" | 1.540" | 0.120" to 0.140" | 2 | 91074A328 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1.000" | 1.540" | 0.120" to 0.140" | 2 | 91074A348 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1.000" | 1.910" | 0.170" to 0.190" | 2 | 91074A353 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M27 | 1.120" | 1.650" | 0.220" to 0.240" | 1 | 91074A354 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M27 | 1.120" | 1.910" | 0.220" to 0.240" | 1 | 91074A355 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 | 1.700" | 2.480" | 0.250" to 0.270" | 1 | 91074A366 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.280" | 0.450" | 0.090" to 0.110" | 10 | 97913A112 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.280" | 0.530" | 0.090" to 0.110" | 10 | 97913A123 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16", M8 | 0.340" | 0.530" | 0.090" to 0.110" | 10 | 97913A113 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.410" | 0.650" | 0.090" to 0.110" | 10 | 97913A114 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.410" | 0.830" | 0.090" to 0.110" | 5 | 97913A125 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.530" | 0.770" | 0.090" to 0.110" | 5 | 97913A117 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.530" | 1.000" | 0.120" to 0.140" | 4 | 97913A128 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8", M16 | 0.670" | 1.000" | 0.120" to 0.140" | 4 | 97913A118 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.790" | 1.210" | 0.120" to 0.140" | 4 | 97913A119 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.790" | 1.540" | 0.120" to 0.140" | 2 | 97913A131 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.100" | 1.540" | 0.120" to 0.140" | 2 | 97913A121 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 0.260" | 0.430" | 0.060" to 0.080" | 10 | 97913A111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 0.260" | 0.530" | 0.090" to 0.110" | 10 | 97913A122 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 0.340" | 0.650" | 0.090" to 0.110" | 10 | 97913A124 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 0.420" | 0.650" | 0.090" to 0.110" | 10 | 97913A115 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 0.420" | 0.830" | 0.090" to 0.110" | 5 | 97913A126 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 0.510" | 0.770" | 0.090" to 0.110" | 5 | 97913A116 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 0.510" | 1.000" | 0.120" to 0.140" | 4 | 97913A127 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 0.670" | 1.210" | 0.120" to 0.140" | 4 | 97913A129 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

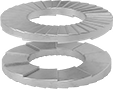

Spring/Wedge Lock

|

More flexible than standard wedge lock washers to withstand stronger shocks and vibration. They have a cone shape that expands and compresses to maintain tension in the joint, similar to a heavy duty spring.

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

For Screw Size | ID | OD | Thk. | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16", M8 | 0.340" | 0.530" | 0.080" to 0.090" | 1 | 93281A103 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16", M8 | 0.340" | 0.650" | 0.080" to 0.090" | 1 | 93281A113 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.410" | 0.650" | 0.090" to 0.100" | 1 | 93281A104 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.530" | 0.770" | 0.130" to 0.140" | 1 | 93281A107 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8", M16 | 0.670" | 1.000" | 0.170" to 0.180" | 1 | 93281A109 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.790" | 1.210" | 0.210" to 0.220" | 1 | 93281A114 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 0.260" | 0.430" | 0.070" to 0.080" | 1 | 93281A101 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 0.420" | 0.650" | 0.100" to 0.110" | 1 | 93281A105 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 0.510" | 0.770" | 0.13" | 1 | 93281A106 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 0.840" | 1.210" | 0.220" to 0.230" | 1 | 93281A112 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SAE Washers

Originally designed for the automotive industry, these washers conform to SAE sizing standards. They generally have smaller diameters than USS washers to fit in cramped spots and are thinner to create more precise gaps. Washers distribute pressure under screws and nuts to protect your mounting surface.

Steel

|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

For Screw Size | ID | OD | Thk. | For Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.158" | 0.380" | 0.036" to 0.065" | SAE Grade 8 | ASME B18.21.1 | 10 | 98180A180 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.190" | 0.443" | 0.036" to 0.065" | SAE Grade 8 | ASME B18.21.1 | 10 | 98180A190 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.221" | 0.505" | 0.036" to 0.065" | SAE Grade 8 | ASME B18.21.1 | 10 | 98180A210 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.625" | 0.055" to 0.065" | SAE Grade 8 | ASME B18.22.1 | 100 | 98180A110 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.344" | 0.688" | 0.055" to 0.065" | SAE Grade 8 | ASME B18.22.1 | 50 | 98180A120 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.812" | 0.055" to 0.065" | SAE Grade 8 | ASME B18.22.1 | 50 | 98180A130 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.469" | 0.922" | 0.055" to 0.065" | SAE Grade 8 | ASME B18.22.1 | 25 | 98180A140 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.531" | 1.062" | 0.097" to 0.177" | SAE Grade 8 | ASME B18.22.1 | 25 | 98180A150 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 0.599" | 1.168" | 0.074" to 0.121" | SAE Grade 8 | ASME B18.21.1 | 5 | 98180A220 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.688" | 1.312" | 0.122" to 0.177" | SAE Grade 8 | ASME B18.22.1 | 25 | 98180A160 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.812" | 1.469" | 0.122" to 0.177" | SAE Grade 8 | ASME B18.22.1 | 20 | 98180A170 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.950" | 1.762" | 0.108" to 0.160" | SAE Grade 8 | ASME B18.21.1 | 1 | 98180A230 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.074" | 2.012" | 0.108" to 0.160" | SAE Grade 8 | ASME B18.21.1 | 1 | 98180A240 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1.262" | 2.243" | 0.108" to 0.160" | SAE Grade 8 | ASME B18.21.1 | 1 | 98180A250 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.387" | 2.512" | 0.136" to 0.192" | SAE Grade 8 | ASME B18.21.1 | 1 | 98180A260 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.637" | 3.012" | 0.136" to 0.192" | SAE Grade 8 | ASME B18.21.1 | 1 | 98180A270 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

General Purpose Washers

Your go-to metal washer for every screw size. Washers take the pressure off nuts and screws to protect mounting surfaces.

Steel

|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

For Screw Size | ID, mm | OD, mm | Thk., mm | For Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 9.0 | 0.7 to 0.9 | ISO Class 8.8 | DIN 125, ISO 7089 | 50 | 91455A410 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 | 10.0 | 0.9 to 1.1 | ISO Class 8.8 | DIN 125, ISO 7089 | 50 | 91455A420 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 12.0 | 1.4 to 1.8 | ISO Class 8.8 | DIN 125, ISO 7089 | 50 | 91455A430 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 | 12.0 | 1.4 to 1.8 | ISO Class 10.9 | DIN 125, ISO 7089 | 100 | 90486A101 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 | 16.0 | 1.4 to 1.8 | ISO Class 8.8 | DIN 125, ISO 7089 | 50 | 91455A440 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 | 16.0 | 1.4 to 1.8 | ISO Class 10.9 | DIN 125, ISO 7089 | 100 | 90486A102 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.5 | 20.0 | 1.8 to 2.2 | ISO Class 8.8 | DIN 125, ISO 7089 | 25 | 91455A450 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.5 | 20.0 | 1.8 to 2.2 | ISO Class 10.9 | DIN 125, ISO 7089 | 100 | 90486A103 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 13.0 | 24.0 | 2.3 to 2.7 | ISO Class 8.8 | DIN 125, ISO 7089 | 10 | 91455A460 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 13.0 | 24.0 | 2.3 to 2.7 | ISO Class 10.9 | DIN 125, ISO 7089 | 100 | 90486A104 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 | 15.0 | 28.0 | 2.3 to 2.7 | ISO Class 8.8 | DIN 125, ISO 7089 | 10 | 91455A470 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 17.0 | 30.0 | 2.7 to 3.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 10 | 91455A480 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 | 19.0 | 34.0 | 2.7 to 3.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 5 | 91455A490 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 21.0 | 37.0 | 2.7 to 3.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 5 | 91455A510 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 1 | 91455A520 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 | 31.0 | 56.0 | 3.7 to 4.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 1 | 91455A530 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Split Lock Washers

|

Stop nuts and screws from loosening due to mild vibration. As you tighten, the uneven ends bite into the nut or screw so it won't back out. While they're not as vibration resistant as other lock washers, they are a great fit for electrical panels, light fixtures, and other light duty assemblies. Split lock washers are not reusable, and they only work with fasteners that have right-hand threads.

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

For Screw Size | ID | OD | Thk. | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.200" | 0.334" | 0.047" | ASME B18.21.1 | 25 | 5185N151 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.260" | 0.487" | 0.062" | ASME B18.21.1 | 25 | 5185N128 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.322" | 0.583" | 0.078" | ASME B18.21.1 | 25 | 5185N129 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.385" | 0.680" | 0.094" | ASME B18.21.1 | 10 | 5185N131 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.450" | 0.776" | 0.109" | ASME B18.21.1 | 10 | 5185N132 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.512" | 0.869" | 0.125" | ASME B18.21.1 | 10 | 5185N133 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 0.574" | 0.965" | 0.141" | ASME B18.21.1 | 5 | 5185N134 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.641" | 1.073" | 0.156" | ASME B18.21.1 | 5 | 5185N135 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.766" | 1.265" | 0.188" | ASME B18.21.1 | 1 | 5185N136 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.894" | 1.459" | 0.219" | ASME B18.21.1 | 1 | 5185N137 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.024" | 1.656" | 0.250" | ASME B18.21.1 | 1 | 5185N138 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.280" | 2.036" | 0.312" | ASME B18.21.1 | 1 | 5185N141 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.5 mm | 11.8 mm | 1.5 mm to 1.7 mm | DIN 127B | 25 | 90491A101 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.5 mm | 14.8 mm | 1.9 mm to 2.1 mm | DIN 127B | 25 | 90491A102 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.7 mm | 18.1 mm | 2.0 mm to 2.4 mm | DIN 127B | 25 | 90491A103 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||