Filter by

Screw Size

System of Measurement

ID

OD

Thickness

Finish

Specifications Met

Fastener Strength Grade/Class

Hardness

Performance

Washer Designation

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Maximum Temperature

Minimum Temperature

Application

For Bearing Nut Face Style

Oversized Washers

These washers have exaggerated diameters to cover large holes and to compensate for uneven mounting surfaces. They are also thicker than general purpose washers, so they bridge wide gaps when used as spacers.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Steel

|

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Blue-Dyed Steel—These metric-sized washers have a distinctive blue color, so you can easily tell them apart from inch washers. The coating provides only minimal corrosion resistance, so these washers are best for dry environments.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 50.0 | 9.0 to 11.0 | DIN 7349 | 1 | 97310A124 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.8 | 72.0 | 4.0 to 6.0 | DIN 9021 | 1 | 91100A230 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 43.0 | 6.0 to 6.9 | — | 5 | 98040A111 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue-Dyed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.0 | 48.0 | 3.4 to 4.6 | — | 5 | 93162A370 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 24.0 | 38.0 | 3.7 to 4.3 | DIN 1440, ISO 8738 | 10 | 96505A125 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 60.0 | 7.0 to 9.0 | DIN 6340 | 1 | 94630A117 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.0 | 85.0 | 5.0 to 7.0 | DIN 440-R | 1 | 98363A119 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

General Purpose Washers

Your go-to metal washer for every screw size. Washers take the pressure off nuts and screws to protect mounting surfaces.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Steel

|

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Zinc-Yellow-Chromate-Plated Steel—With the same corrosion resistance as zinc-plated steel, these withstand occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Steel—Best for dry environments since moisture will cause these washers to rust.

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

Black Super-Corrosion-Resistant-Coated Steel—Combines a finished appearance with the rust resistance of 316 stainless steel. The coating has been tested to extreme standards, including 1,000 hours of salt spray resistance, to hold up in wet and outdoor environments. Also known as black luster.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

For Screw Size | ID, mm | OD, mm | Thk., mm | For Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | — | DIN 125, ISO 7089 | 25 | 91166A330 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 5 | 91455A190 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | ISO Class 10.9 | DIN 125, ISO 7089 | 10 | 91455A618 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | ISO Class 10.9 | DIN 125, ISO 7089 | 1 | 90483A174 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.2 | 44.0 | 3.9 | ISO Class 12.9 | DIN 125 | 10 | 90483A107 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | — | DIN 125 | 1 | 98687A327 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.0 | 44.0 | 3.4 to 4.6 | — | DIN 126, ISO 7091 | 10 | 98687A119 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | ISO Class 8.8 | DIN 125, ISO 7089 | 1 | 91455A520 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Super-Corrosion-Resistant-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.3 to 4.3 | — | DIN 125, ISO 7089 | 1 | 93413A334 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass

|

Softer than most metals, brass washers won't damage other fastening components.

Brass—With a warm, polished look, these washers are often chosen for their appearance. Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 3.7 to 4.3 | DIN 125, ISO 7089 | 1 | 91635A410 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Washers

|

All of these washers are lightweight, nonconductive, and naturally rust resistant. They are commonly used in electronics and automation applications to take the pressure off screws and nuts and protect mounting surfaces.

Nylon—The most popular plastic washers, these are strong, durable, and economical. Nylon will swell and weaken when exposed to moisture, so these washers are best for dry environments.

Acid-Resistant PVC—A great choice for chemical-processing lines, these washers won't degrade when exposed to harsh acids, alkalis, and alcohols. They are also good electrical insulators.

Chemical-Resistant High-Temperature PTFE—The most chemical-resistant plastic washers we offer, these stand up to the widest range of harsh acids, bases, solvents, and corrosive cleaners, even at temperatures up to 500° F. Their slippery surface reduces friction between the washer, fastener, and mounting surface to prevent sticking when tightening and loosening. They are also good electrical insulators.

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Min. | Max. | Specs. Met | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.3 | 44.0 | 3.7 to 4.3 | -40 | 220 | DIN 125 | Off-White | 10 | 95610A112 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acid-Resistant PVC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 42.0 | 1.3 to 1.7 | Not Rated | 140 | — | Gray | 5 | 95611A148 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant High-Temperature PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 1.4 to 1.8 | Not Rated | 500 | — | White | 1 | 95630A330 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Abrasion-Resistant Leather Cushioning Washers

|

These leather washers are nonmarring and they resist wear from rubbing and scraping surfaces. Use them to cushion joints and dampen vibration.

For Screw Size | ID, mm | OD, mm | Thk. | Min. Temp. | Max. Temp., ° F | Hardness | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Leather | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.000 | 44.000 | 0.094" to 0.156" | Not Rated | 150 | Durometer 75A | Beige | 10 | 95576A180 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Undersized Washers

These washers distribute pressure evenly under fasteners with narrow heads, such as cheese and socket head screws. They have smaller diameters than general purpose washers of the same screw size.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Steel

|

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

For Screw Size | ID, mm | OD, mm | Thk., mm | For Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 39.0 | 3.7 to 4.3 | — | DIN 433, ISO 7092 | 5 | 98688A124 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 39.0 | 3.7 to 4.3 | ISO Class 8.8 | DIN 433 | 1 | 98688A183 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 39.0 | 3.7 to 4.3 | ISO Class 10.9 | DIN 433 | 1 | 98688A162 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 40.0 | 3.5 to 4.4 | — | — | 5 | 98035A111 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 39.0 | 3.7 to 4.3 | — | DIN 433 | 5 | 98687A129 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

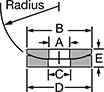

Leveling Washers

|

|

|

Also known as spherical washers, these consist of a male and female washer that, when nested, swivel slightly to compensate for tolerance variations and uneven surfaces. They're good for die and fixturing applications.

18-8 Stainless Steel—18-8 stainless steel washers have good chemical resistance and may be mildly magnetic. These washers are the most corrosion-resistant option.

Leveling Washers | Replacement Male Leveling Washers | Replacement Female Leveling Washers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Male, mm | Female, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Screw Size | ID (A) | OD (B) | Radius | ID (C) | OD (D) | Thk. (E), mm | Max. Angle of Correction | Hardness | Specs. Met | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 32.0 | 28.0 | 44.0 | 14.7 to 15.4 | 3° | Not Rated | DIN 6319 | 94007A057 | 000000 | 94007A117 | 000000 | 94007A217 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 44.0 | 32.0 | 28.0 | 44.0 | 14.7 to 15.4 | 3° | Not Rated | DIN 6319 | 98148A178 | 00000 | 98148A108 | 00000 | 98148A208 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Vibration-Resistant Wedge Lock Washers

When it's critical to keep bolted assemblies secure, choose these two-piece lock washers with the tightest grip of all. They stop nuts and screws from loosening in heavy machinery that experiences jarring starts and stops, such as compressors and compactors. Serrations on the outside bite into the fastener and mating surfaces, while wedges on the inside lock the two pieces together. When the nut or screw starts to loosen, the wedges drive more tightly together to maintain tension. You can reuse these washers up to fifteen times, as long as the serrations and wedges are not worn down. They are comparable to NORD-LOCK® or Sherex TEC® washers.

Wedge Lock

|

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Super-Corrosion-Resistant Zinc-Flake-Coated Steel—With 40 times the corrosion resistance of zinc-plated steel, these withstand rust as well as 316 stainless steel. They have been tested to extreme standards, including 1,000 hours of salt spray. They are similar to Magni-coated washers.

For Screw Size | ID | OD | Thk. | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1.000" | 1.540" | 0.120" to 0.140" | 1 | 91812A790 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1.000" | 1.910" | 0.120" to 0.140" | 1 | 91812A796 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant Zinc-Flake-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1.000" | 1.540" | 0.120" to 0.140" | 2 | 91074A348 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1.000" | 1.910" | 0.170" to 0.190" | 2 | 91074A353 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealing Washers

Prevent leaks while distributing weight evenly under nuts and screws. These washers compress as you tighten to keep air and fluid in, and dust and contaminants out. Use them anywhere you need a tight seal, such as protecting electronics from moisture or keeping lubricants contained in machinery.

Rubber

|

Resist leaks better than metal sealing washers, but are more susceptible to wear and tear. Reuse these washers a handful of times, as long as the material isn't damaged.

Neoprene—If you're not sure which material best suits your needs, these versatile washers are a great solution. They offer a good balance of strength and flexibility to hold a tight seal, even in wet and outdoor conditions. These washers also withstand salt water and mild chemicals, such as detergents. However, they don't resist oil, grease, or fuel as well as Buna-N washers.

Weather-Resistant EPDM—The best choice for outdoor use, these washers withstand long-term exposure to sunlight, rain, and ozone. However, they can't handle oil, grease, or fuel like Buna-N washers can.

Metal

|

Also known as crush washers, these are made of soft metal that deforms under pressure to fill gaps around the nut or screw. Often found in oil drain valves, they withstand stress and wear better than plastic and rubber washers, but aren't as leak-resistant. Metal sealing washers are not reusable.

Copper—Softer than aluminum washers, these deform easily to create a tight seal with less effort. They resist rusting in corrosive environments, but will develop a green patina over time.

Cellulose-Filled Copper—The easiest washers to crush. These washers are embedded with cellulose, which makes them more flexible than other metal washers for a tighter seal. They resist rusting in corrosive environments, but will develop a green patina over time.

Aluminum—These washers are an economical alternative to copper. They have similar corrosion resistance but require more effort to crush.

Hard Fiber Washers

|

The least likely to scratch or mar delicate mounting surfaces, these washers are made of hardened cotton fiber. They are also naturally nonconductive, so they are a great choice for insulating nuts and screws to prevent unintended charges. However, fiber washers will break down faster than other washers and will need to be replaced more often.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Color | Pkg. Qty. | Pkg. | ||

|---|---|---|---|---|---|---|---|---|---|

| M24 | 25 | 44 | 2.8 to 3.5 | DIN 125 | Black | 10 | 95225A355 | 00000 |

ASME Washers

Also known as Type B washers, these meet ASME sizing standards. They take the pressure off screws and nuts to protect your mounting surface.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

High-Pressure Bonded Sealing Washers

Tested to hold up to high pressures, these washers create the strongest seal of all to lock in air and fluid and keep equipment running efficiently. They are often used on flanged connections to prevent leaks in pumps, hydraulic systems, compressors, and other pressurized lines. The flexible rubber or plastic layer compresses to fills gaps, while the metal backing stops the washer from squeezing through the hole.

For Screw Heads

|

|

Fit under screw heads to stop leaks. These washers seal best on screws that aren't threaded all the way up to the head. Reuse them a handful of times, as long as the material isn't damaged.

Oil-Resistant Zinc-Plated Steel and Buna-N—These washers won't swell or soften when they touch oil, grease, and fuel. However, they will degrade if exposed to synthetic lubricants. They are also are more susceptible to rusting than 18-8 and 316 stainless steel.

Max. Pressure, psi | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | For Fluids | For Gases | Min. | Max. | Color | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Zinc-Plated Steel and Buna-N | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 23.7 | 43.9 | 1.5 to 1.8 | 5,500 | 200 | -10 | 240 | Black | 1 | 93786A350 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

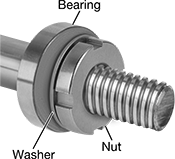

Bearing Spring Lock Washers for Slotted Bearing Nuts

|  |

For Stepped Nuts |

Designed for use with bearing nuts, these lock washers have a conical shape that presses like a spring against bearings, bushings, gears, and pulleys to hold them in place on your threaded shaft or spindle. They also have an inner tab that sits in the shaft or spindle’s keyway to prevent the nut from loosening.

Steel—Steel washers are strong and flexible.

DIN 462—DIN 462 and DIN 5406 washers meet international standards for lock washer dimensions. Pair DIN 462 washers with DIN 1804 bearing nuts, and DIN 5406 washers with DIN 981 bearing nuts.

Tab, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Wd. | Dp. | Overall Ht., mm | Hardness | Specs. Met | For Bearing Nut Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Stepped Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 24.000 | 42.000 | 1.000 | 6.000 | 2.500 | 4.000 | Not Rated | DIN 462 | DIN 1804 | 90407A121 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Split Lock Washers

|

Stop nuts and screws from loosening due to mild vibration. As you tighten, the uneven ends bite into the nut or screw so it won't back out. While they're not as vibration resistant as other lock washers, they are a great fit for electrical panels, light fixtures, and other light duty assemblies. Split lock washers are not reusable, and they only work with fasteners that have right-hand threads.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Zinc-Yellow-Chromate-Plated Steel—With the same corrosion resistance as zinc-plated steel, these withstand occasional exposure to moisture.

Blue-Dyed Steel—These metric-sized washers have a distinctive blue color, so you can easily tell them apart from inch washers. The coating provides only minimal corrosion resistance, so these washers are best for dry environments.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 40.0 | 4.8 to 5.2 | DIN 127B | 10 | 92148A271 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 40.0 | 4.8 to 5.2 | DIN 127B | 5 | 92153A449 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 40.0 | 4.8 to 5.2 | DIN 127B | 25 | 91202A261 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 40.0 | 4.8 to 5.2 | DIN 127B | 10 | 96982A163 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue-Dyed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 24.5 | 40.7 | 7.2 | ASME B18.21.2M | 10 | 93279A700 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 40.0 | 4.8 to 5.2 | DIN 127B | 25 | 91169A248 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Structural Washers

Distribute pressure under structural screws and nuts in columns, joists, and I-beams. These thick washers are tested and certified to meet industry standards for handling high-stress loads.

Steel

|

Steel—Best for dry environments since moisture will cause these washers to rust.

Corrosion-Resistant Galvanized Steel—These washers combine the strength of steel with the rust resistance of stainless steel. They're an economical alternative to 18-8 stainless steel in wet and outdoor environments, but they won't hold up to salt water and chemicals.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

Heavy-Vibration-Resistant Spring Lock Washers

|

With a grip that's second only to wedge lock, these washers stop nuts and screws from wiggling loose under constant, vigorous vibration. They are ideal for engines, turbines, generators, and other heavy duty equipment. Similar to a spring, they flatten under pressure to add tension between mating surfaces. As long as the washers aren't deformed or otherwise damaged, you can reuse them indefinitely without losing locking strength. Also known as conical washers and Belleville washers.

Stack multiple washers in the same direction to double or triple how much weight they can bear. Stack washers in opposite directions for better deflection, which means they compress further and withstand more shock and movement without loosening.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Phosphate-Coated Steel—Paint adheres evenly to the surface of these washers, so you can add your own decorative finish. They are more durable than zinc-plated steel washers to withstand wet and outdoor environments. However, they won't hold up to the harsh chemicals that stainless steel can.

Steel—Best for dry environments since moisture will cause these washers to rust.

DIN 432—These washers have a small tab that presses up against the flats of your nut or screw for extra security.

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 50.0 | 1.6 | 6.5 | DIN 432 | 1 | 97471A131 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 56.0 | 6.0 | 7.8 | DIN 6796 | 1 | 95221A133 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 56.0 | 6.0 | 7.8 | DIN 6796 | 1 | 95221A213 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 50.0 | 1.6 | 6.5 | DIN 432 | 1 | 97471A112 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 | 56.0 | 6.0 | 7.8 | DIN 6796 | 1 | 93497A340 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tension-Indicating Structural Washers

Fasten structural screws and nuts securely without overtightening. When you see orange dye, you'll know you've applied the correct tension, so you don't accidentally strip threads. These washers distribute pressure under fasteners in columns, joists, and I-beams. They are tested and certified to meet industry standards for handling high-stress loads.

Steel

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Corrosion-Resistant Galvanized Steel—These washers combine the strength of steel with the rust resistance of stainless steel. They're an economical alternative to 18-8 stainless steel in wet and outdoor environments, but they won't hold up to salt water and chemicals.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

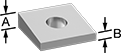

Square Washers

With flat sides, these washers fit into slots and channels and won't rotate out of position. They are also wider and thicker than most round washers, so they distribute heavier loads across a larger surface area. Square washers are commonly used to anchor heavy machinery, fasten framing to floors, and hang pipe and conduit from strut channel.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Material Certificate—Washers include a report with a traceable lot number.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

For Screw Size | ID, mm | Wd., mm | Thk., mm | Certificate Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 32.0 | 50.0 | 6.0 | Material Certificate | 91122A310 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel

|

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Corrosion-Resistant Galvanized Steel—These washers combine the strength of steel with the rust resistance of stainless steel. They're an economical alternative to 18-8 stainless steel in wet and outdoor environments, but they won't hold up to salt water and chemicals.

Material Certificate—Washers include a report with a traceable lot number.

Tooth Lock Washers

Grip tighter than split lock washers to prevent nuts and screws from loosening in applications with constant movement, such as conveyors. Tooth lock washers typically can't be reused because the teeth often get bent when tightened.

External Tooth

|

Teeth on the outside edge bite into both the fastener and the mating surface for a stronger hold than internal-tooth lock washers. However, they may mar your material and snag on objects. Pair these washers with nuts and screws that are large enough to make contact with the teeth, such as pan, button, and binding head screws.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

DIN 6798—Best for slightly bumpy or irregular surfaces because the teeth are angled to make even contact with the material.

Internal Tooth

|

Internal teeth dig into the nut or screw to prevent it from backing out. Unlike external-tooth lock washers, these have a smooth outside edge, so they are less likely to mar your material or snag on objects. However, they don’t grip quite as well. Pair them with fasteners that have small diameters, such as fillister and cheese head screws.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Leveling Washers for I-Beams

Mounted on an I-Beam |

|

Commonly called beveled washers, these are tapered to fit inside an I-beam's flange to provide a parallel bearing surface.

18-8 Stainless Steel—18-8 stainless steel washers have good chemical resistance and may be mildly magnetic. These washers are the most corrosion-resistant option.

Zinc-Plated Steel—Zinc-plated steel washers are coated for corrosion resistance in wet environments.

Galvanized Steel—Galvanized steel washers are ten times more corrosion resistant than zinc-plated washers.

Wave Spring Lock Washers

|

The wavy shape flexes like a spring to keep nuts and screws secure on slightly uneven surfaces. These washers add a small amount of tension to stop fasteners from backing out due to mild vibration. While they don't hold as well as other lock washers, they do grip slightly better than curved washers. They work best in electrical panels, light fixtures, and other light duty assemblies. Since these washers hold their shape when untightened, you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

DIN 128B—These washers have split ends that bite into your material surface for a tighter hold than other wave washers.

Heavy-Vibration-Resistant Spring Lock Washers for Socket Head Screws

|

Stop socket head screws from wiggling loose on equipment with constant, vigorous vibration, such as engines, turbines, and generators. These washers have a small diameter to fit under screws with narrow heads. Similar to a spring, they flatten under pressure to add tension between mating surfaces. As long as the washers aren't deformed or otherwise damaged, you can reuse them indefinitely without losing locking strength. Also known as conical washers and Belleville washers.

Stack multiple washers in the same direction to double or triple how much weight they can bear. Stack washers in opposite directions for better deflection, which means they compress further and withstand more shock and movement without loosening.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these washers to rust.

Top-and-Bottom Serration—Adds friction for extra gripping power.

Curved Spring Lock Washers

|

The curvy, spring-like shape adds a small amount of tension to prevent nuts and screws from backing out due to mild vibration. These washers also flex slightly to compensate for uneven surfaces. While more secure than a standard flat washer, these have the least amount of gripping power of all our lock washers. They are best suited for electrical panels, light fixtures, and other light duty assemblies. These washers hold their shape when untightened, so you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

DIN 128A—These washers have split ends that bite into your material surface for a tighter hold than other curved washers.

Split Lock Washers for Socket Head Screws

|

Stop socket head screws from loosening due to mild vibration. These washers have a small diameter to fit under screws with narrow heads, but are still thick enough to keep fasteners secure. While they're not as vibration resistant as other lock washers, they are a great fit for electrical panels, light fixtures, and other light duty assemblies. Split lock washers are not reusable, and they only work with fasteners that have right-hand threads. Also known as high-collar lock washers.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 35.9 | 4.8 to 5.2 | DIN 7980 | 5 | 91111A151 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 35.9 | 4.8 to 5.2 | DIN 7980 | 1 | 94241A640 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 35.9 | 4.8 to 5.2 | DIN 7980 | 10 | 93837A190 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.5 | 35.9 | 4.8 to 5.2 | DIN 7980 | 10 | 91190A630 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||