Colorimeters

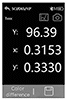

Ensure consistent coloring on products such as labels and packaging. The sensor on these colorimeters translates the light an object reflects to an exact color reading. Use them for quality control to prevent slight variation that you might miss with your eyes alone. Calibrate your colorimeter using the included white calibration block. The machine measures all other colors according to their variance from true white.

Color calibration plates (sold separately) test and calibrate your colorimeter. They include five colors across the color spectrum to give the device a reference point for exact color readings. Precisely manufactured to ISO/IEC 17025, these plates meet standards for testing and calibration equipment.

Colorimeters | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Illumination | Color Calibration Plates | ||||||||||||||

| Repeatability | Field of View | Ht. | Wd. | Dp. | Distribution | Angle | Color Space | Color Distance Formula | Batteries Included | Features | Includes | Each | Each | ||

LED with Visible Light Spectrum | |||||||||||||||

USB-C Connection | |||||||||||||||

| ΔE*ab ≤ 0.03 | 10° | 6 1/2" | 2 1/2" | 3 1/2" | Diffuse | 8° | CIE Lab, CIE LCh, CIE Luv, CMYK, Hex, RGB, Yxy | ΔE*ab, ΔE*uv, ΔE*94, ΔE*cmc (2:1), ΔE*cmc (1:1), ΔE*00 | Yes | Storage for up to 1,000 Colors, Storage for up to 1,000 Comparisons | 3 ft. Long USB Cord, AC Adapter, Microfiber Cloth, White Calibration Block | 0000000 | 0000000 | 0000000 | 000000000 |

Light Spectrum Meters

Screen

Display

Evaluate how dyes, pharmaceuticals, food products, and raw materials respond to light to determine their purity and quality. Also known as spectrophotometers, these are often used to measure how a sample’s concentration changes when exposed to light. They measure absorbance and transmittance to check how much light is absorbed or passes through a sample. They also take reflectance measurements to help you test paint and coatings by checking how much light bounces off them. To use these meters, point the light toward your sample.

Fields of view represent how the human eye sees color. The 2° field of view mimics viewing color up close. The 10° field of view mimics viewing color as you’d see it from a few feet away.

Aperture sizes control the amount of light you expose your sample to. Use the 11 mm aperture to measure textured samples and average color over a larger area. The 6 mm aperture is best for general purpose measurements. The 3 mm × 1 mm aperture measures small samples.

Diffuse illumination distribution means these meters scatter light around your sample for even coverage. This gives you accurate readings on rough and uneven surfaces. The 8° illumination angle reduces light reflections when measuring glossy materials.

Color spaces give numbered color values for standard colors in different industries. These meters support standard color spaces for printing, textiles, digital displays, food and pharmaceuticals, and lighting design.

Color distance formulas measure how different two colors are from each other. ΔE76 is used for comparison in general purpose, non-critical applications. ΔECMC is often used to measure textiles, ceramics, and uneven or glossy surfaces. ΔE94 is often used to measure paints and coatings for vehicles. ΔE2000 is the most accurate and precise measurement formula. It is the standard adopted by ISO. You’ll see it used in applications where color measurements are more critical, such as laboratories or pharmaceutical manufacturing facilities.

Illumination | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wavelength Measurement Range | Measuring Increments | Accuracy | Repeatability | Field of View | Aperture Size | Distribution | Angle | Color Space | Color Distance Formula | Each | |

LED with Visible Light Spectrum | |||||||||||

Bluetooth and USB-C Connection | |||||||||||

| 400-700 nm | 10 nm | ΔE*ab ≤ 0.25 | ΔE*ab ≤ 0.025 | 2°, 10° | 11 mm Dia. (Medium) 6 mm Dia. (Small) 3 mm Lg. × 1 mm Wd. (Extra Small) | Diffuse | 8° | CIE Lab, CIE LCh, CIE Luv, CMYK, HunterLab, RGB, Yxy | ΔE*ab, ΔE*94, ΔE*cmc, ΔE*00 | 0000000 | 000000000 |

Photoelectric Color-Measuring Transmitters

Monitor the color of products as they pass by on your line. These transmitters don’t just detect if color is in mint condition—they also turn equipment on or off, all with a single device. They’re often used for quality control in printing and packaging lines. For instance, if ink runs low and causes a color’s hue to fade, they can send a signal to pause production. The photoelectric sensor uses a highly accurate LED beam that combines red, green, and blue (RGB), which detects the slightest shifts in color at high speeds. It can even sense gradual color changes on glossy and mirrored surfaces. Rated IP67, these transmitters are protected against dust and temporary submersion.

Transmitters with IO Link translate and send readings to control systems, such as computers, programmable logic controllers (PLCs), and human-machine interfaces (HMIs). This also lets you send commands from your control system to these transmitters. Since they have a PNP/NPN signal output, they automatically produce the type of signal output needed based on the device they’re connected to.

Cables with a socket (sold separately) connect transmitters to your control system or directly to compatible machinery.

For technical drawings and 3-D models, click on a part number.

Transmitters | Cables with Socket | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sensing Distance, mm | Input Voltage | Current Output | Signal Output Type | Communication Protocol | Lg. | Wd. | Ht. | Housing Material | Each | Each | ||

With 4-Pole Micro M12 Plug | ||||||||||||

Direct Sensing Transmitter with Visible LED Light Beam | ||||||||||||

| 10 | 10-30V DC | 100mA | PNP, NPN | IO Link | 3 13/16" | 1 3/16" | 2 1/8" | Zinc | 0000000 | 0000000 | 0000000 | 000000 |