Filter by

Diameter

Pin Type

End Type

Head Diameter

Material

Performance

Finish

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Nose Material

Body Material

Minimum Hardness

Plunger Locking Type

Steel Grade

Hardness

Handle Material

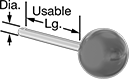

Fully Grooved Dowel Pins with Rounded Head

The domed head creates a finished appearance, so these pins are often used to attach brackets, knobs, and machine plates. The grooves pinch shut when you press pins into a hole, creating tension to lock them in place.

For the best fit, drill your hole slightly larger than the nominal diameter shown.

Steel

Zinc-Plated Carbon Steel—These pins withstand occasional exposure to moisture. However, since friction from moving parts can wear away the finish, they're not ideal for wet environments. While not nearly as corrosion resistant as stainless steel, they are stronger and won’t deform under stress.

Parallel Groove—Fit tighter than pins with tapered grooves to stay in place under severe vibration. However, they require more force to insert.

Nominal | Max. | Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Dia. | Dia. Tolerance | Dia. | Dia. Tolerance | Groove Type | Double Shear Breaking Strength | Min. Hardness | Dia. | Ht. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.086" | -0.002" to 0" | 0.096" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.154" | 0.065" | ASME B18.8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.104" | -0.002" to 0" | 0.113" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.202" | 0.08" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.086" | -0.002" to 0" | 0.096" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.154" | 0.065" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.104" | -0.002" to 0" | 0.113" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.202" | 0.08" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.12" | -0.002" to 0" | 0.13" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.25" | 0.097" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.144" | -0.002" to 0" | 0.153" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.298" | 0.113" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.086" | -0.002" to 0" | 0.096" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.154" | 0.065" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.104" | -0.002" to 0" | 0.113" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.202" | 0.08" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.12" | -0.002" to 0" | 0.13" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.25" | 0.097" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.144" | -0.002" to 0" | 0.155" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.298" | 0.113" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.161" | -0.002" to 0" | 0.171" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.347" | 0.13" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.196" | -0.002" to 0" | 0.206" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.395" | 0.146" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.12" | -0.002" to 0" | 0.13" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.25" | 0.097" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.144" | -0.002" to 0" | 0.155" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.298" | 0.113" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.161" | -0.002" to 0" | 0.171" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.347" | 0.13" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.196" | -0.002" to 0" | 0.201" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.395" | 0.146" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.161" | -0.002" to 0" | 0.171" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.347" | 0.13" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.196" | -0.002" to 0" | 0.201" | -0.002" to 0.002" | Parallel | Not Rated | Not Rated | 0.395" | 0.146" | ASME B18.8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

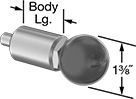

Ball-Grip Quick-Release Pins

The smooth, round head is comfortable to grip and won't catch on other parts. These pins have a retaining ball that holds them in place until you pull to remove.

Steel

|

Zinc-Plated Carbon Steel—These pins withstand occasional exposure to moisture. However, since friction from moving parts can wear away the finish, they're not ideal for wet environments. While not nearly as corrosion resistant as stainless steel, they are stronger and won’t deform under stress.

Usable Lg. | Dia. at Extended Ball Ht. | Single Shear Breaking Strength, lbf | Min. Hardness | Handle Color | Handle Material | Ball Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.286" | 1,900 | Rockwell C26 | Black | Plastic | Stainless Steel | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.286" | 1,900 | Rockwell C26 | Black | Plastic | Stainless Steel | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.286" | 1,900 | Rockwell C26 | Black | Plastic | Stainless Steel | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 0.426" | 4,300 | Rockwell C26 | Black | Plastic | Stainless Steel | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" | 0.426" | 4,300 | Rockwell C26 | Black | Plastic | Stainless Steel | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 0.57" | 7,700 | Rockwell C26 | Black | Plastic | Stainless Steel | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed Dowel Pins with Rounded Head

Often used in place of rivets, these pins create a finished look while securing plastics and soft metals such as aluminum. The sharp points bite into parts for a permanent hold. Also known as Barb-Lok™ pins.

Steel

Zinc-Plated Carbon Steel—These pins withstand occasional exposure to moisture. However, since friction from moving parts can wear away the finish, they're not ideal for wet environments. While not nearly as corrosion resistant as stainless steel, they are stronger and won’t deform under stress.

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Double Shear Breaking Strength | Min. Hardness | Dia. | Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/64" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | Not Rated | Not Rated | 0.211" | 0.087" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Not Rated | Not Rated | 0.211" | 0.087" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Not Rated | Not Rated | 0.211" | 0.087" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Not Rated | Not Rated | 0.26" | 0.103" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Not Rated | Not Rated | 0.26" | 0.103" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Not Rated | Not Rated | 0.26" | 0.103" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9/64" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Not Rated | Not Rated | 0.309" | 0.119" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Not Rated | Not Rated | 0.309" | 0.119" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Not Rated | Not Rated | 0.309" | 0.119" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11/64" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Not Rated | Not Rated | 0.359" | 0.136" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Not Rated | Not Rated | 0.359" | 0.136" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Not Rated | Not Rated | 0.359" | 0.136" | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball-Grip Weld-On Retractable Spring Plungers

|

The smooth ball handle is easy to grip and won't catch on other parts. Pull it back to manually retract the nose and make adjustments whenever you need. Since they weld in place, these spring plungers have the strongest hold for aligning, securing, and positioning components on heavy machinery. They can do everything from locking attachments on forklifts and holding dies in place on industrial presses. To change your setup, unthread the spring plunger from the old welded-on barrel and thread it into a new one.

Zinc-Plated Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. They withstand occasional exposure to moisture.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Twist-to-Lock—Free up both hands to adjust your workpiece or switch out parts without the plunger springing back and getting in the way. Pull back the handle and twist to lock the nose in its retracted position.

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle | Nonlocking | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Material | Lg. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.25" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 4.5" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 3" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.688" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

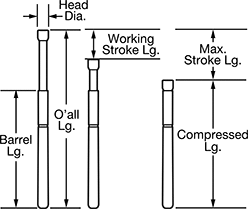

Spring Test Probes

Round Tip |

|

Create an automated system to test continuity in circuit boards. Combine these spring-loaded test probes with Spring Test Probe Sockets that are permanently attached to testing fixtures. Select a socket that has the same minimum spacing between probe centers and is for the probe's barrel length. Test probes and sockets are sold separately.

Probes with flat and rounded tips are nonmarring, while probes with pointier tips may leave light marks on surfaces. Sharper probes, however, will be more effective at penetrating corroded or finished surfaces.

When installing test probes and sockets, adhere to the "minimum spacing between probe centers" to maximize testing points while preventing probes from interfering with each other. Spring test probes will produce optimal results when your system is set up to achieve the working stroke length. Initial spring force is the force required to start compressing the probe; maximum spring force is the force applied at the working stroke length.

Round Tip—Round probes test flat surfaces.

Spring Force, ozf | Stroke Lg. | Barrel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. Spacing Between Probe Centers | Current, amp | Initial | Max. | Overall Lg. | Compressed Lg. | Working | Max. | Lg. | Dia. | Head Dia. | Finish | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 4.3 | 2.2 | 5.4 | 1.435" | 1.27" | 0.167" | 1/4" | 1.435" | 0.024" | 0.016" | Gold Plated | 5 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 1.7 | 7 | 1.865" | 1.548" | 0.317" | 0.35" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 2.4 | 5.6 | 1.36" | 1.12" | 0.167" | 1/4" | 1.09" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5.9 | 1.2 | 4.8 | 1.527" | 1.21" | 0.317" | 0.4" | 1.09" | 0.031" | 0.021" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 10 | 1.7 | 7 | 1.45" | 1.13" | 0.317" | 0.35" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 5 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.059" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 27 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.059" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 32 | 4 | 10 | 1.33" | 1.07" | 0.17" | 1/4" | 0.97" | 0.09" | 0.068" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||