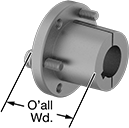

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

Bushings with a machine key fit into a matching keyway on a sprocket or pulley for high-torque applications.

304 stainless steel bushings are often used in food-processing plants and other frequently-cleaned areas because washdowns and humidity won’t corrode them. They have a pilot hole instead of a finished keyway, so you can bore them to the exact dimensions of your shaft.

For technical drawings and 3-D models, click on a part number.

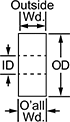

Keyway | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Steel | |||||||

H Style Bushing | |||||||

| 3/8" | 1 1/4" | __ | __ | 3° | 95 | 00000000 | 000000 |

| 1/2" | 1 1/4" | 1/8" | 1/16" | 3° | 95 | 00000000 | 00000 |

| 5/8" | 1 1/4" | 3/16" | 3/32" | 3° | 95 | 00000000 | 00000 |

| 3/4" | 1 1/4" | 3/16" | 3/32" | 3° | 95 | 00000000 | 00000 |

| 7/8" | 1 1/4" | 3/16" | 3/32" | 3° | 95 | 00000000 | 00000 |

| 1" | 1 1/4" | 1/4" | 1/8" | 3° | 95 | 00000000 | 00000 |

| 1 1/8" | 1 1/4" | 1/4" | 1/8" | 3° | 95 | 00000000 | 00000 |

| 1 3/16" | 1 1/4" | 1/4" | 1/8" | 3° | 95 | 00000000 | 00000 |

| 1 1/4" | 1 1/4" | 1/4" | 1/8" | 3° | 95 | 00000000 | 00000 |

| 1 3/8" | 1 1/4" | 5/16" | 1/16" | 3° | 95 | 00000000 | 00000 |

| 1 7/16" | 1 1/4" | 3/8" | 7/64" | 3° | 95 | 00000000 | 00000 |

| 1 1/2" | 1 1/4" | 3/8" | 5/64" | 3° | 95 | 00000000 | 00000 |

| 10mm | 1 1/4" | __ | __ | 3° | 95 | 00000000 | 00000 |

| 12mm | 1 1/4" | __ | __ | 3° | 95 | 00000000 | 00000 |

| 14mm | 1 1/4" | 5mm | 2mm | 3° | 95 | 00000000 | 00000 |

| 16mm | 1 1/4" | 5mm | 2mm | 3° | 95 | 00000000 | 00000 |

| 18mm | 1 1/4" | 6mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 19mm | 1 1/4" | 6mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 20mm | 1 1/4" | 6mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 22mm | 1 1/4" | 6mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 24mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 25mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 28mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 30mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 00000 |

H Style Bushing with Machine Key | |||||||

| 32mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 00000 |

| 35mm | 1 1/4" | __ | __ | 3° | 95 | 00000000 | 00000 |

| 38mm | 1 1/4" | __ | __ | 3° | 95 | 00000000 | 00000 |

304 Stainless Steel | |||||||

H Style Bushing | |||||||

| 3/8"-1 1/2" | 1 1/4" | __ | __ | 3° | 95 | 00000000 | 000000 |

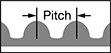

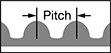

High-Strength HTD Timing Belt Pulleys

These HTD (high torque drive) pulleys have a curved tooth shape that provides higher strength than trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

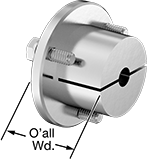

Bushing-mount pulleys grip the shaft more securely than pulleys that press fit. Quick-disconnect (QD) bushings and split-tapered bushings sold separately.

For technical drawings and 3-D models, click on a part number.

| For Belt Trade Size | OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Each | |

For 20 mm Max. Belt Wd. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H8M | 74.93 | 26 | 8 | 1.375" | Finished | Quick Disconnect Style JA | 22.23 | 28.58 | 28.58 | 66.217 | 2 | Machined | Black-Oxide Iron | 00000000 | 000000 |

| H8M | 80.01 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 22.23 | 28.58 | 28.58 | 71.297 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 85.09 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 22.23 | 28.58 | 28.58 | 76.403 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 97.03 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.7 | 28.7 | 86.588 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 109.99 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.7 | 28.7 | 101.854 | 2 | Machined | Black-Oxide Iron | 0000000 | 00000 |

| H8M | 120.91 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.7 | 28.7 | 112.039 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 131.07 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.7 | 28.7 | 122.224 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 151.13 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.7 | 28.7 | 142.595 | 2 | Machined | Black-Oxide Iron | 00000000 | 000000 |

For 30 mm Max. Belt Wd. | |||||||||||||||

| H8M | 80.01 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 71.297 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 85.09 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 76.403 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 89.92 | 32 | 8 | 1.625" | Finished | Split Tapered Style H | 31.88 | 38.23 | 38.23 | 81.483 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 97.03 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.88 | 38.23 | 38.23 | 86.588 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 109.99 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.88 | 38.23 | 38.23 | 101.854 | 2 | Machined | Black-Oxide Iron | 0000000 | 00000 |

| H8M | 120.91 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.88 | 38.23 | 38.23 | 112.039 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 131.07 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.88 | 38.23 | 38.23 | 122.224 | 2 | Machined | Black-Oxide Iron | 00000000 | 00000 |

| H8M | 151.13 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.88 | 38.23 | 38.23 | 142.595 | 2 | Machined | Black-Oxide Iron | 00000000 | 000000 |

High-Strength Corrosion-Resistant HTD Timing Belt Pulleys

Move belts forward and backward or stop and start them in precise positions, especially in areas where rust is a concern. The curved teeth on these high-torque drive (HTD) pulleys have more surface contact with belts than traditional trapezoidal teeth, which allows you to apply more torque without damaging belts. These teeth fit together seamlessly to prevent backlash, or unwanted movement of the belt on the pulley, for a smooth, quiet cycle. These pulleys are often used in 3D printing, machine tool drives, robotics, and other applications where precision is essential. They are also known as curvilinear belt pulleys.

Pair pulleys with an HTD timing belt that has the same pitch. The width of your belt should not be larger than the maximum belt width listed.

Stainless steel pulleys can be wetted repeatedly without rusting or staining.

Bushing-mount pulleys grip the shaft more securely than press-fit pulleys, but require a quick-disconnect (QD) bushing or a split-tapered bushing (not included).

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Each | |

For 20 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 70 | 26 | 8 | 1.374" | Finished | Quick Disconnect Style JA | 22.35 | 28.58 | 28.58 | 62.22 | 2 | Machined | 0000000 | 0000000 |

| 80.17 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 22.35 | 28.58 | 28.58 | 71.3 | 2 | Machined | 0000000 | 000000 |

| 84.94 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 22.35 | 28.58 | 28.58 | 76.4 | 2 | Machined | 0000000 | 000000 |

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.58 | 28.58 | 86.59 | 2 | Machined | 0000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.58 | 28.58 | 101.854 | 2 | Machined | 000000 | 000000 |

| 120.65 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 112.04 | 2 | Machined | 0000000 | 000000 |

| 130.99 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 122.22 | 2 | Machined | 0000000 | 000000 |

| 150.8 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 141.224 | 2 | Machined | 0000000 | 000000 |

For 30 mm Max. Belt Wd. | |||||||||||||

| 78.49 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 33.32 | 38.1 | 38.1 | 71.3 | 2 | Machined | 0000000 | 000000 |

| 84.94 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 76.4 | 2 | Machined | 0000000 | 000000 |

| 90.48 | 32 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 81.48 | 2 | Machined | 0000000 | 000000 |

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.75 | 38.1 | 38.1 | 86.59 | 2 | Machined | 000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.75 | 38.1 | 38.1 | 101.854 | 2 | Machined | 0000000 | 000000 |

| 120.65 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 112.04 | 2 | Machined | 0000000 | 000000 |

| 130.99 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 122.22 | 2 | Machined | 0000000 | 000000 |

| 150.8 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 142.6 | 2 | Machined | 0000000 | 000000 |

High-Strength Ultra-Quiet Timing Belt Pulleys

Teeth are curved and set in an offset pattern for high strength with 25% less operating noise than pulleys and belts with trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

Bushing-mount pulleys grip the shaft more securely than pulleys that press fit. Quick-disconnect (QD) bushings and split-tapered bushings sold separately.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Fabrication | Material | Each | |

For 16 mm Max. Belt Wd. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 69.85 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 17 | 17 | 71 | Cast | Magnesium-Phosphate-Coated Iron | 0000000 | 0000000 |

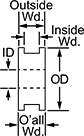

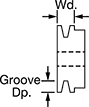

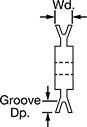

Split-Tapered Bushing-Bore V-Belt Pulleys

These pulleys have the same sizing versatility as quick-disconnect pulleys, but they create a tighter grip on bushings for use in high-torque applications. The same pulley can be used with different shaft diameters; choose a Style H split-tapered bushing with the bore size you need.

For technical drawings and 3-D models, click on a part number.

| OD | Pitch Dia. (For Belt Trade Size) | Wd. | O'all Wd. | Groove Dp. | Material | Body Type | Each | |

| 3.15" | 2.4" (4L, A), 2.8" (5L, B) | 7/8" | 1 5/16" | 0.625" | Cast Iron | Solid | 0000000 | 000000 |

| 3.55" | 2.8" (4L, A), 3.2" (5L, B) | 7/8" | 1 21/64" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 3.75" | 3" (4L, A), 3.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 3.95" | 3.2" (4L, A), 3.6" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 4.25" | 3.5" (4L, A), 3.9" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 4.75" | 4" (4L, A), 4.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 4.95" | 4.2" (4L, A), 4.6" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 5.75" | 5" (4L, A), 5.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 5.95" | 5.2" (4L, A), 5.6" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 6.25" | 5.5" (4L, A), 5.9" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Solid | 0000000 | 00000 |

| 6.75" | 6" (4L, A), 6.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Spoked | 0000000 | 00000 |

| 7.75" | 7" (4L, A), 7.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Spoked | 0000000 | 00000 |

| 8.25" | 7.5" (4L, A), 7.9" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Spoked | 0000000 | 00000 |

| 12.75" | 12" (4L, A), 12.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Spoked | 0000000 | 000000 |

| 15.75" | 15" (4L, A), 15.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Spoked | 0000000 | 000000 |

| 18.75" | 18" (4L, A), 18.4" (5L, B) | 7/8" | 7/8" | 0.625" | Cast Iron | Spoked | 0000000 | 000000 |