How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

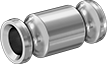

Selecting and Measuring Expansion Joints

For information about selecting pipe size, see Selecting and Measuring Pipe & Fittings.

More

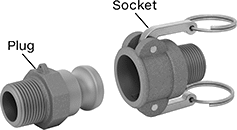

Metal Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of metal, these couplings have better durability than plastic cam-and-groove couplings. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Couplings are compatible with Andrews, Dixon, Ever-Tite, and PT cam-and-groove couplings.

Aluminum fittings are lighter in weight than 316 stainless steel fittings. They have good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: Fed. Spec. A-A-59326

Plug connectors are also known as SA spool adapters.

| Coupling Size | Plug OD | Max. Pressure | Each | |

Aluminum | ||||

|---|---|---|---|---|

| 1 | 1 7/16" | 250 psi @ 72° F | 000000000 | 000000 |

| 1 1/2 | 2 1/8" | 250 psi @ 72° F | 000000000 | 00000 |

| 2 | 2 1/2" | 250 psi @ 72° F | 00000000 | 00000 |

| 3 | 3 5/8" | 200 psi @ 72° F | 00000000 | 00000 |

| 4 | 4 3/4" | 150 psi @ 72° F | 00000000 | 00000 |

316 Stainless Steel | ||||

| 1 | 1 7/16" | 250 psi @ 72° F | 000000000 | 000000 |

| 1 1/2 | 2 1/8" | 250 psi @ 72° F | 000000000 | 000000 |

| 2 | 2 1/2" | 250 psi @ 72° F | 0000000 | 000000 |

| 3 | 3 5/8" | 200 psi @ 72° F | 0000000 | 000000 |

| 4 | 4 3/4" | 150 psi @ 72° F | 0000000 | 000000 |

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: Fed. Spec. A-A-59326

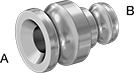

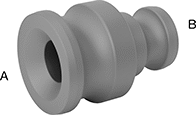

Plug reducers are also known as SA spool adapters.

Coupling Size | Plug OD | |||||

|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Max. Pressure | Each | |

Aluminum | ||||||

| 1 1/2 | 1 | 2 1/8" | 1 7/16" | 250 psi @ 72° F | 000000000 | 000000 |

| 2 1/2 | 2 | 3" | 2 1/2" | 200 psi @ 72° F | 000000000 | 00000 |

| 3 | 2 | 3 5/8" | 2 1/2" | 200 psi @ 72° F | 00000000 | 00000 |

| 4 | 3 | 4 3/4" | 3 5/8" | 150 psi @ 72° F | 00000000 | 00000 |

316 Stainless Steel | ||||||

| 3 | 2 | 3 5/8" | 2 1/2" | 200 psi @ 72° F | 0000000 | 000000 |

| 4 | 3 | 4 3/4" | 3 5/8" | 150 psi @ 72° F | 0000000 | 000000 |

Cam-and-Groove Hose Couplings for Vapor Recovery

Connect your hose to a cam-and-groove vapor recovery valve. The probe inside these couplings opens the valve when connected to start recovery. They’re often used when offloading fuel.

Socket connectors are also known as C×C couplers.

- Maximum Pressure: 100 psi @ 72° F

- Temperature Range: -40° to 250° F

- Compatible With: Dixon Vapor Valves, PT Coupling Vapor Valves, OPW Vapor Valves

Levers | ||||||

|---|---|---|---|---|---|---|

| Coupling Size | Socket ID | No. of | Material | Pull Ring Material | Each | |

Aluminum | ||||||

| 4 | 4 3/4" | 4 | Bronze | Steel | 0000000 | 0000000 |

Metal Cam-and-Groove Hose Couplings for Water

A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Aluminum couplings are lighter in weight than brass plugs and sockets. They have good abrasion and corrosion resistance thanks to their anodized finish. Brass couplings are softer than aluminum plugs and sockets, so they’re easier to thread together. They have good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Plug connectors and reducers are also known as SA spool adapters.

| Coupling Size | Plug OD | Max. Pressure | Each | |

Anodized Aluminum | ||||

|---|---|---|---|---|

| 1 | 1 7/16" | 250 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 2 1/8" | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 2 1/2" | 250 psi @ 72° F | 00000000 | 00000 |

| 3 | 3 5/8" | 200 psi @ 72° F | 00000000 | 00000 |

| 4 | 4 3/4" | 150 psi @ 72° F | 00000000 | 000000 |

Brass | ||||

| 1 | 1 7/16" | 250 psi @ 72° F | 000000000 | 00000 |

| 2 | 2 1/2" | 250 psi @ 72° F | 000000000 | 000000 |

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Plug connectors and reducers are also known as SA spool adapters.

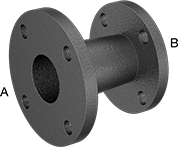

FM-Approved Iron Pipe Fittings with Flanged Ends

FM approved, these fittings are suitable for use in fire-protection systems. All have flat-surface flanged ends that only mate to another same-size flat-surface flange, pump, or valve with a gasket (sold separately) to create an access point in a pipeline. Use them in noncorrosive areas.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASTM B307, Fed. Spec. WW-F-406, ASME B16.1, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 steel

Pipe Size | Flange OD | Bolt Hole | Bolt Circle Dia. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | For Bolt Dia. | Dia. | No. of | (A) | (B) | Max. Pressure | Max. Steam Pressure | Material | Each | |

| 2 1/2 | 2 | 7" | 6" | 5/8" | 3/4" | 4 | 5 1/2" | 4 3/4" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 0000000 |

| 3 | 2 | 7 1/2" | 6" | 5/8" | 3/4" | 4 | 6" | 4 3/4" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 000000 |

| 3 | 2 1/2 | 7 1/2" | 7" | 5/8" | 3/4" | 4 | 6" | 5 1/2" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 000000 |

| 4 | 3 | 9" | 7 1/2" | 5/8" | 3/4" | 8 | 7 1/2" | 6" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 000000 |

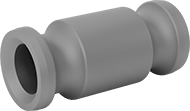

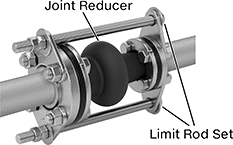

Expansion Joint Reducers with Flanged Ends

Connect different pipe sizes in your line while adding a point of flexibility between them. These expansion joints absorb movement between two connected pipes to reduce stress, vibration, and noise. Their flanged ends mate with same-size Class 150 flanges without the need for a gasket. Each flange is supported by a zinc-plated steel plate. The body of these expansion joints is reinforced with cord for added strength.

Your pipe system must be rigidly anchored on both sides of the expansion joint to control expansion or contraction of the line. When proper anchoring cannot be provided, limit rods (sold separately) are required.

- For Use With: Air, Alcohol, Calcium Chloride, Coolant, Grain Alcohol, Grease, Hydraulic Fluid, Sodium Carbonate (20% in Water), Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: See Table

- Maximum Vacuum: 26 in. of Hg @ 72° F

Unthreaded Bolt Holes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flange OD | Pipe Size | No. of Bolt Holes | Distance | Bolt Hole Size | ||||||||||||

(A) | (B) | (A) | (B) | Lg. | (A) | (B) | Compression | Expansion | Offset | Max. Pressure | Expansion Joint Type | Flange Material | (A) | (B) | Each | |

EPDM Rubber | ||||||||||||||||

| 6" | 4 1/4" | 2 | 1 | 8" | 4 | 4 | 1" | 1/2" | 1/2" | 200 psi @ 72° F | Single Bulb | EPDM Rubber | 3/4" | 5/8" | 0000000 | 0000000 |

| 6" | 5" | 2 | 1 1/2 | 8" | 4 | 4 | 1" | 1/2" | 1/2" | 200 psi @ 72° F | Single Bulb | EPDM Rubber | 3/4" | 5/8" | 0000000 | 000000 |

| 7 1/2" | 6" | 3 | 2 | 8" | 4 | 4 | 1 3/8" | 11/16" | 1/2" | 200 psi @ 72° F | Single Bulb | EPDM Rubber | 3/4" | 3/4" | 0000000 | 000000 |

| 9" | 6" | 4 | 2 | 8" | 8 | 4 | 1 3/8" | 11/16" | 1/2" | 200 psi @ 72° F | Single Bulb | EPDM Rubber | 3/4" | 3/4" | 0000000 | 000000 |

| 9" | 7 1/2" | 4 | 3 | 8" | 8 | 4 | 1 3/8" | 11/16" | 1/2" | 200 psi @ 72° F | Single Bulb | EPDM Rubber | 3/4" | 3/4" | 0000000 | 000000 |

| 11" | 9" | 6 | 4 | 8" | 8 | 8 | 1 9/16" | 3/4" | 1/2" | 190 psi @ 72° F | Single Bulb | EPDM Rubber | 7/8" | 3/4" | 0000000 | 00000000 |

| 13 1/2" | 11" | 8 | 6 | 8" | 8 | 8 | 1 9/16" | 3/4" | 1/2" | 190 psi @ 72° F | Single Bulb | EPDM Rubber | 7/8" | 7/8" | 0000000 | 00000000 |

For Pipe Size | |||||

|---|---|---|---|---|---|

| (A) | (B) | Rod Lg. | Includes | Pkg. | |

| 2 | 1 | 14" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 0000000 |

| 2 | 1 1/2 | 14" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 000000 |

| 3 | 2 | 14" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 000000 |

| 4 | 2 | 14" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 000000 |

| 4 | 3 | 14" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 000000 |

| 6 | 4 | 14" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 000000 |

| 8 | 6 | 17" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 000000 |

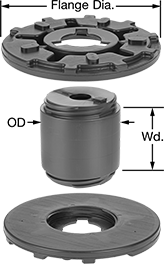

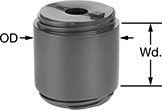

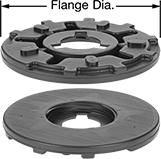

Build-Your-Own Spools

Select the core and flanges you need to create a custom spool for storing twine, wire, rope, and chain. Flanges are threaded and have tabs for nonslip stacking.

Note: For each spool, order one core plus one pair of flanges.

| Wd. | Core OD | Core ID | Color | Material | Each | |

| 4 1/2" | 6" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| 6" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 7" | 6" | 2 1/4" | Black | Plastic | 00000000 | 0000 |

| 7" | 8" | 2" | Black | Plastic | 00000000 | 0000 |

| 9" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 10" | 8" | 2" | Black | Plastic | 00000000 | 0000 |

| 10" | 11" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| 11" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 12" | 11" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| 13" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 13" | 8" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 16" | 8" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| 17" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 17" | 6" | 2 1/4" | Black | Plastic | 00000000 | 0000 |

| 19" | 8" | 2 1/4" | Black | Plastic | 00000000 | 00000 |

| 19" | 11" | 3" | Black | Plastic | 00000000 | 00000 |

| 20" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 23" | 6" | 1 1/2" | Black | Plastic | 00000000 | 0000 |

| 25" | 8" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| 28" | 6" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| 28" | 11" | 1 1/2" | Black | Plastic | 00000000 | 00000 |

| Flange Dia. | Color | Material | Features | Pair | |

| 12" | Black | Plastic | Nonslip Tabs | 00000000 | 000000 |

| 14" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |

| 16" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |

| 18" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |

| 20" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |

| 22" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |

| 24" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |

| 28" | Black | Plastic | Nonslip Tabs | 00000000 | 00000 |