Filter by

Tip Style

Component

For Joining

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Use With

Cooling Capacity

Maximum Flow Rate @ Pressure

Temperature Control

Cooling Method

Stud Welders

Threaded Studs

Copper-Plated Steel | 18-8 Stainless Steel | Aluminum | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | For Collet Thread Size | Head Dia. | Lg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | |||||

| 4-40 | 4-40 | 3/16" | 1/2" | 100 | 0000000 | 000000 | — | ——— | 0 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 3/8" | 100 | 00000000 | 00000 | 100 | 00000000 | 000000 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 1/2" | 100 | 0000000 | 0000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 3/4" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 1 1/2" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 3/8" | 100 | 00000000 | 00000 | — | ——— | 0 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 1/2" | 100 | 0000000 | 0000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 5/8" | 100 | 00000000 | 00000 | — | ——— | 0 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 3/4" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 10-24 | 10-24 | 1/4" | 1/2" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 10-24 | 10-24 | 1/4" | 3/4" | — | ——— | 0 | — | ——— | 0 | 100 | 00000000 | 000000 | ||

| 10-24 | 10-24 | 1/4" | 1" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 10-32 | 10-32 | 1/4" | 3/8" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 10-32 | 10-32 | 1/4" | 1/2" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 10-32 | 10-32 | 1/4" | 3/4" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 1/2" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | 100 | 00000000 | 00000 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 5/8" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 3/4" | 100 | 00000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 1" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | 100 | 00000000 | 00000 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 1 1/2" | — | ——— | 0 | 100 | 00000000 | 000000 | — | ——— | 0 | ||

Spot Welding Electrodes

Shank Taper No. | Dia. | Lg. | For Joining | Tip Dia. | Material | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pointed with Offset Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 31/64" | 3" | Steel, Stainless Steel | 3/16" | 182 Copper | RWMA Bulletin 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 3" | Steel, Stainless Steel | 1/4" | 182 Copper | RWMA Bulletin 16 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pointed with Straight Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 31/64" | 3" | Steel, Stainless Steel | 3/16" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 3" | Steel, Stainless Steel | 1/4" | 182 Copper | RWMA Bulletin 16 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pointed with Double-Bent Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 3" | Steel, Stainless Steel | 1/4" | 182 Copper | RWMA Bulletin 16 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat with Straight Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 31/64" | 3" | Steel, Stainless Steel | 31/64" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 3" | Steel, Stainless Steel | 5/8" | 182 Copper | RWMA Bulletin 16 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat with Swivel Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 1" | 2 1/64" | Steel, Stainless Steel | 1" | 182 Copper | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 1" | 2 1/64" | Steel, Stainless Steel | 1" | 182 Copper | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Convex with Straight Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 3" | Aluminum, Brass, Bronze | 1/4" | 150 Copper | RWMA Bulletin 16 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spot Welding Electrode Cleaners

For Electrode Type | Lg. | Wd. | Head Wd. | Each | ||

|---|---|---|---|---|---|---|

| RWMA Shank Taper No. 4, RWMA Shank Taper No. 5, Dome Nose | 8" | 3/4" | 1 1/4" | 0000000 | 0000000 |

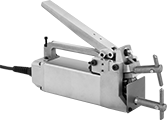

Spot Welders

Spot Welders | Replacement Spot Welding Arms | Replacement Spot Welding Electrodes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Input (Single Phase) | Arm | Overall | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Max. Material Thk. | Duty Cycle | Voltage, V AC | Frequency, Hz | Output Power, kVA | Ht. | Dp. | Ht. | Wd. | Dp. | Wt., lb. | Connection | No. of Blades | Cord Lg., ft. | Each | Pair | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5 Seconds On, 5 Seconds Off | 220 | 60 | 2.5 | 3 3/4" | 4 15/16" | 9" | 3 1/2" | 14 1/2" | 25 | Straight Blade | 3 | 12 | 0000000 | 000000000 | 0000000 | 0000000 | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Water Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 5 Seconds On, 5 Seconds Off | 220 | 60 | 6 | 3 11/16" | 5 7/8" | 9" | 3 1/2" | 14 1/2" | 25 | Straight Blade | 3 | 12 | 000000 | 00000000 | 0000000 | 000000 | 2 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap-Style Spot Welding Electrodes

Spot Welding Electrodes | Spot Welding Electrode Shanks | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Shank Taper No. | Dia. | Lg. | For Joining | Tip Dia. | Material | Specs. Met | Each | Lg. | For Gender | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pointed Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 31/64" | 1 1/8" | Steel, Stainless Steel | 3/16" | 182 Copper | RWMA Bulletin 16 | 0000000 | 00000 | 2 1/4" | Male | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 1 1/4" | Steel, Stainless Steel | 1/4" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | 2 1/4" | Male | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 31/64" | 27/32" | Steel, Stainless Steel | 3/16" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | 2 1/4" | Female | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 7/8" | Steel, Stainless Steel | 3/16" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | 2 1/4" | Female | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 4 | 31/64" | 1 1/8" | Steel, Stainless Steel | 31/64" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | 2 1/4" | Male | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RWMA 5 | 5/8" | 1 1/4" | Steel, Stainless Steel | 5/8" | 182 Copper | RWMA Bulletin 16 | 0000000 | 0000 | 2 1/4" | Male | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Band Saw Blade Welders

For Blade | Input | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Welding Process | Material | Wd. | Thk. | Duty Cycle | Voltage, V AC | Freq., Hz | Electrical Phase | Output Power, kVA | Ht. | Wd. | Dp. | Wt., lb. | Cord Lg., ft. | Each | ||

| Spot | Carbon Steel, Bi-Metal | 1/16" to 1" | 0.025" to 0.035" | 3 Seconds On, 57 Seconds Off | 240 | 60 | Single | 3.5 | 12" | 8" | 10" | 78 | 3 1/2 | 000000 | 000000000 | |

Low-Temperature Liquid Chillers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Voltage (Electrical Phase) | Current, amp | Compressor Power, hp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Temp. Control Range, ° F | Ht. | Wd. | Dp. | Tank Cap., gal. | Refrigerant No. | Features | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Closed-Loop Fluid Cooling Systems | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13,600 | 460V AC (Three Phase) | 22 | 2 | 10 gpm @ 28 psi | 150 | 0 to 40 | 54 3/8" | 31 5/8" | 31 5/8" | 12 | R-448A | Liquid-Level Sight Glass | Canada | 0000000 | 0000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rack-Mount Liquid Chillers

|

Temp. Control | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rack Wd. | Cooling Cap., BTU/hr | Voltage (Electrical Phase) | Current, amp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Range, ° F | Method | Ht. | Wd. | Dp. | Tank Cap., gal. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Closed-Loop Fluid Cooling Systems | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thermoelectric Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19" | 600 | 100V AC-240V AC (Single Phase) | 2.5 | 0.8 gpm @ 5 psi | 10 | 50 to 140 | External Controller, Keypad | 7" | 19" | 13 1/2" | 0.3 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Liquid Chillers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Current, amp | Compressor Power, hp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Temp. Control Range, ° F | Temp. Tolerance, ° F | Ht. | Wd. | Dp. | Electrical Connection Type | Tank Cap., gal. | Refrigerant No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC (Single Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,900 | 13.7 | 1/4 | 3.5 gpm @ 90 psi | 90 | 15 to 155 | -18 to 18 | 21 7/8" | 15" | 26" | Plug In | 1.1 | R-513A | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5,940 | 17.4 | 1/2 | 3.5 gpm @ 90 psi | 90 | 15 to 155 | -18 to 18 | 21 7/8" | 15" | 26" | Plug In | 1.1 | R-513A | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC (Single Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10,920 | 15.5 | 1 1/4 | 6 gpm @ 45 psi | 45 | 50 to 80 | -0.09 to 0.09 | 30 9/16" | 14 1/8" | 31 13/16" | Plug In | 1.5 | R-513A | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24,000 | 33.4 | 3 | 10 gpm @ 45 psi | 45 | 50 to 80 | -0.09 to 0.09 | 34 7/8" | 18" | 33 13/16" | Hardwire | 2.5 | R-513A | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36,000 | 45.3 | 4 1/4 | 10 gpm @ 45 psi | 45 | 50 to 80 | -0.09 to 0.09 | 49 3/8" | 18" | 31 13/16" | Hardwire | 2.5 | R-513A | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bench-Top Liquid Chillers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Wire Connection | Voltage (Electrical Phase) | Current, amp | Compressor Power, hp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Temp. Control Range, ° F | Ht. | Wd. | Dp. | Accuracy | Tank Cap., fl. oz. | Refrigerant No. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Closed-Loop Fluid Cooling Systems | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thermoelectric Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | Wire Leads | 24V DC | 12.5 | — | 1 gpm @ 10 psi | 20 | 50 to 140 | 9 1/16" | 5 1/8" | 6 5/16" | ±0.4% | 4 | — | Semi-Clear Tank Inlet | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Refrigerant Cooled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,400 | — | 120V AC (Single Phase) | 3.3 | 1/6 | 6 gpm @ 16 psi | 16 | 0 to 80 | 18 7/16" | 9 1/8" | 18 3/16" | ±1.8% | 51 | R-513A | UV Light System | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Liquid Chillers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Current, amp | Compressor Power, hp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Temp. Control Range, ° F | Ht. | Wd. | Dp. | Electrical Connection Type | Connection End Type | Tank Cap., gal. | Refrigerant No. | Features | Cannot Be Sold To | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC (Single Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,100 | 13 | 1/4 | 2 gpm @ 50 psi | 50 | 50 to 80 | 28 5/8" | 22" | 21 1/8" | Plug In | — | 5 | R-513A | Bypass Valve, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,300 | 15.5 | 1/2 | 4 gpm @ 50 psi | 50 | 50 to 80 | 28 5/8" | 22" | 21 1/8" | Plug In | — | 5 | R-513A | Bypass Valve, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC (Single Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11,300 | 17 | 1 | 4 gpm @ 50 psi | 50 | 50 to 80 | 33 3/8" | 31 1/8" | 25 1/8" | Plug In | — | 10 | R-513A | Bypass Valve, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC (Three Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 11 | 1 1/2 | 4 gpm @ 50 psi | 50 | 50 to 80 | 33 3/8" | 31 1/8" | 25 1/8" | Hardwire | — | 10 | R-513A | Bypass Valve, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24,000 | 22 | 2 | 10 gpm @ 35 psi | 35 | 50 to 80 | 35 7/8" | 34 1/8" | 31 5/8" | Hardwire | — | 10 | R-513A | Bypass Valve, Cleanable Air-Intake Filter, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

460V AC (Three Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 6 | 1 | 4 gpm @ 50 psi | 50 | 50 to 80 | 33 3/8" | 24 3/8" | 34 3/8" | Plug In | Male Receptacle | 12 | R-513A | Bypass Valve, Electrical Cords with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24,000 | 10 | 3 | 10 gpm @ 35 psi | 35 | 50 to 80 | 35 5/8" | 33 1/8" | 31 5/8" | Hardwire | — | 10 | R-513A | Bypass Valve, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36,000 | 11 | 3 | 10 gpm @ 45 psi | 45 | 50 to 80 | 65" | 37" | 34 1/2" | Hardwire | — | 36 | R-407C | Bypass Valve, Cleanable Air-Intake Filter, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | California, Canada | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 54,000 | 16 | 5 | 15 gpm @ 45 psi | 45 | 50 to 80 | 68 1/2" | 37" | 34 1/2" | Hardwire | — | 36 | R-513A | Bypass Valve, Cleanable Air-Intake Filter, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 78,400 | 26 | 10 | 30 gpm @ 40 psi | 40 | 50 to 80 | 65 1/2" | 37" | 57" | Hardwire | — | 50 | R-513A | Bypass Valve, Cleanable Air-Intake Filter, Electrical Controls with Shut-Off Switch, Liquid-Level Sight Glass | — | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||