Filter by

System of Measurement

Seal ID

Seal OD

Cylinder Seal Type

Groove Diameter

For Use With

For Shaft Motion

For Cylinder Type

Spring Material

RoHS

REACH

Maximum Speed

DFARS Specialty Metals

Export Control Classification Number (ECCN)

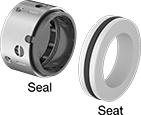

Spring-Loaded Seals

|  | |

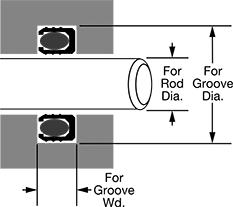

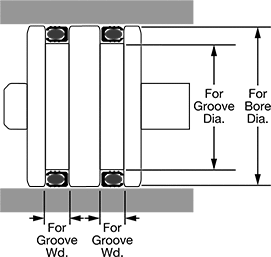

Side 1 | Side 2 | Profile |

|  |

Rod Installation | Piston Installation |

For Rod Sealing | For Piston Sealing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | For Groove Dia. | For Bore Dia. | For Groove Dia. | Max. Speed, ft/sec | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UHMW Polyethylene with 302 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.101" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.250" | 1/4" | 0.125" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.313" | 5/16" | 0.188" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 3/8" | 0.250" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 1/2" | 0.375" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.149" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.375" | 3/8" | 0.188" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.438" | 7/16" | 0.250" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.563" | 9/16" | 0.375" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.688" | 11/16" | 0.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.938" | 15/16" | 0.750" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.188" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.268" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.875" | 1 7/8" | 1.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.875" | 2 7/8" | 2.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UHMW Polyethylene with 316 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.056" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.188" | 3/16" | 0.125" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE with 302 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.056" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.188" | 3/16" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.101" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.250" | 1/4" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.313" | 5/16" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 3/8" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 1/2" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.149" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.375" | 3/8" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.438" | 7/16" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.563" | 9/16" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.688" | 11/16" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.938" | 15/16" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.188" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.268" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.875" | 1 7/8" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.875" | 2 7/8" | 2.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Graphite-Filled PTFE with 302 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.056" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.188" | 3/16" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.101" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.250" | 1/4" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.313" | 5/16" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 3/8" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 1/2" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.149" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.375" | 3/8" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.438" | 7/16" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.563" | 9/16" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.688" | 11/16" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.938" | 15/16" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.188" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.268" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.875" | 1 7/8" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.875" | 2 7/8" | 2.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty Mechanical Pump Shaft Seals

Seal | Seat | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Mfr./Brand Equiv. | ID | OD | Wd. | ID | OD | Wd. | Washer | Seat | Max. Pressure, psi | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Case and 316 Stainless Steel Spring with Viton® Fluoroelastomer Diaphragm and Viton® Fluoroelastomer Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | John Crane Type 8T Pac-Seal Type 8T | 0.625" | 1.062" | 0.937" | 0.661" | 1.250" | 0.406" | Carbon | Ceramic | 300 | Outside North America | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | John Crane Type 8T Pac-Seal Type 8T | 0.750" | 1.187" | 0.937" | 0.781" | 1.375" | 0.406" | Carbon | Ceramic | 300 | Outside North America | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | John Crane Type 8T Pac-Seal Type 8T | 1.000" | 1.437" | 1.000" | 1.064" | 1.625" | 0.437" | Carbon | Ceramic | 300 | Outside North America | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | John Crane Type 8T Pac-Seal Type 8T | 1.250" | 1.687" | 1.000" | 1.281" | 1.875" | 0.437" | Carbon | Ceramic | 300 | Outside North America | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | John Crane Type 8T Pac-Seal Type 8T | 1.500" | 1.937" | 1.125" | 1.546" | 2.125" | 0.437" | Carbon | Silicon Carbide | 300 | Outside North America | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||