Filter by

Measures

Barrel Diameter

Head Diameter

Weight Measuring Increments

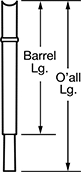

Overall Length

Weight Capacity

Barrel Length

Current

Length

Wire Connection Method

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Compressed Length

Maximum Spring Force

Spring Testers

Cap. | Accuracy | Measuring Increments | Ht. | Wd. | Dp. | Disc Dia. | Data Connection | Voltage, V AC | Cord Lg., ft. | Includes | Display Type | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Measures Compression and Tension | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 lb. 1 kg 10 N | ±0.01 kg ±0.02 lb. ±0.1 N | 0.0001 lb. 0.0001 kg 0.001 N | 23 5/8" | 9 5/16" | 11 13/16" | 1 3/16" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 lb. 2 kg 20 N | ±0.04 lb. ±0.02 kg ±0.2 N | 0.0002 lb. 0.0002 kg 0.002 N | 23 5/8" | 9 5/16" | 11 13/16" | 1 3/16" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 lb. 3 kg 30 N | ±0.06 lb. ±0.03 kg ±0.3 N | 0.001 lb. 0.001 kg 0.01 N | 23 5/8" | 9 5/16" | 11 13/16" | 1 3/16" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 lb. 5 kg 50 N | ±0.05 kg ±0.1 lb. ±0.5 N | 0.001 lb. 0.001 kg 0.01 N | 24 3/8" | 9 5/16" | 11 13/16" | 1 7/8" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 lb. 10 kg 100 N | ±0.1 kg ±0.2 lb. ±1 N | 0.002 lb. 0.002 kg 0.02 N | 24 3/8" | 9 5/16" | 11 13/16" | 1 7/8" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 lb. 20 kg 200 N | ±0.4 lb. ±0.2 kg ±2 N | 0.005 lb. 0.005 kg 0.05 N | 24 3/8" | 9 5/16" | 11 13/16" | 1 7/8" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 lb. 30 kg 300 N | ±0.65 lb. ±0.3 kg ±3 N | 0.01 lb. 0.01 kg 0.1 N | 24 3/8" | 9 5/16" | 11 13/16" | 1 7/8" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 lb. 50 kg 500 N | ±1 lb. ±0.5 kg ±5 N | 0.01 lb. 0.01 kg 0.1 N | 24 3/8" | 9 5/16" | 11 13/16" | 1 7/8" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 lb. 100 kg 1,000 N | ±2 lb. ±1 kg ±10 N | 0.02 lb. 0.02 kg 0.2 N | 36 3/16" | 9 5/16" | 11 13/16" | 4 3/16" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 450 lb. 200 kg 2,000 N | ±2 kg ±20 N ±4.5 lb. | 0.05 lb. 0.05 kg 0.5 N | 36 3/16" | 9 5/16" | 11 13/16" | 4 3/16" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 lb. 500 kg 5,000 N | ±10 lb. ±5 kg ±50 N | 0.1 lb. 0.1 kg 1 N | 36 3/16" | 9 5/16" | 11 13/16" | 4 3/16" | DB9 | 120 | 5 | One Roll of Printer Paper | Digital | Peak-Hold Setting Displacement Measurement Automatic Release Printer Automatic Shutoff | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring Test Probes

| ||

Round Tip | 90° Cup Tip | |

| ||

Flat Tip | Waffle Tip | Crown Tip |

| ||

30° Spear Tip | Chisel Tip | 90° Razor Tip |

| ||

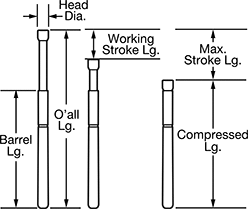

Spring Force, ozf | Stroke Lg. | Barrel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. Spacing Between Probe Centers | Current, amp | Initial | Max. | Overall Lg. | Compressed Lg. | Working | Max. | Lg. | Dia. | Head Dia. | Finish | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

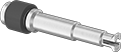

Round Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 4.3 | 2.2 | 5.4 | 1.435" | 1.27" | 0.167" | 1/4" | 1.435" | 0.024" | 0.016" | Gold Plated | 5 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 1.7 | 7 | 1.865" | 1.548" | 0.317" | 0.35" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 2.4 | 5.6 | 1.36" | 1.12" | 0.167" | 1/4" | 1.09" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5.9 | 1.2 | 4.8 | 1.527" | 1.21" | 0.317" | 0.4" | 1.09" | 0.031" | 0.021" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 10 | 1.7 | 7 | 1.45" | 1.13" | 0.317" | 0.35" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 5 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.059" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 27 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.059" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 32 | 4 | 10 | 1.33" | 1.07" | 0.17" | 1/4" | 0.97" | 0.09" | 0.068" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90° Cup Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 0.6 | 2.5 | 0.66" | 0.56" | 0.07" | 0.1" | 0.52" | 0.03" | 0.04" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.035" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 2.4 | 5.6 | 1.36" | 1.12" | 0.167" | 1/4" | 1.09" | 0.031" | 0.035" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 3 | 1.5 | 3.8 | 0.67" | 0.55" | 0.07" | 0.1" | 0.49" | 0.04" | 0.06" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.046" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 12 | 2.2 | 5.5 | 0.97" | 0.89" | 0.107" | 0.16" | 0.73" | 0.054" | 0.075" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.062" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.062" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 23 | 2.2 | 7 | 1.3" | 1.22" | 0.167" | 1/4" | 0.97" | 0.08" | 0.1" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 41 | 2.2 | 7 | 1.3" | 1.22" | 0.167" | 1/4" | 0.97" | 0.08" | 0.1" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 5 | 2.8 | 7 | 1.33" | 1.08" | 0.17" | 1/4" | 0.97" | 0.09" | 0.16" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 5 | 2.8 | 16.4 | 1.42" | 1.17" | 0.17" | 1/4" | 1.07" | 0.13" | 0.16" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 32 | 4 | 10 | 1.33" | 1.07" | 0.17" | 1/4" | 0.97" | 0.09" | 0.16" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 43 | 2.2 | 6 | 1.32" | 1.07" | 0.167" | 1/4" | 0.97" | 0.093" | 0.155" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 55 | 7 | 18 | 1.42" | 1.17" | 0.167" | 1/4" | 1.07" | 0.125" | 0.155" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.035" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 2.4 | 5.6 | 1.36" | 1.12" | 0.167" | 1/4" | 1.09" | 0.031" | 0.035" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 10 | 1.7 | 7 | 1.45" | 1.13" | 0.317" | 0.35" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.046" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.062" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.062" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 5 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.1" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 32 | 4 | 10 | 1.33" | 1.07" | 0.17" | 1/4" | 0.97" | 0.09" | 0.16" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 39 | 7.2 | 18.7 | 1.42" | 1.17" | 0.17" | 1/4" | 1.07" | 0.13" | 0.16" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Waffle Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 0.6 | 2.5 | 0.66" | 0.56" | 0.07" | 0.1" | 0.52" | 0.03" | 0.04" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.035" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 2.4 | 5.6 | 1.36" | 1.12" | 0.167" | 1/4" | 1.09" | 0.031" | 0.035" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 3 | 1.5 | 3.8 | 0.67" | 0.55" | 0.07" | 0.1" | 0.49" | 0.04" | 0.06" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 10 | 1.7 | 7 | 1.45" | 1.13" | 0.317" | 0.35" | 1" | 0.04" | 0.046" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.046" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 12 | 2.2 | 5.5 | 0.97" | 0.89" | 0.107" | 0.16" | 0.73" | 0.054" | 0.075" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.062" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.062" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 23 | 2.2 | 7 | 1.3" | 1.22" | 0.167" | 1/4" | 0.97" | 0.08" | 0.1" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 41 | 2.2 | 7 | 1.3" | 1.22" | 0.167" | 1/4" | 0.97" | 0.08" | 0.1" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 5 | 2.8 | 7 | 1.33" | 1.08" | 0.17" | 1/4" | 0.97" | 0.09" | 0.16" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 5 | 2.8 | 16.4 | 1.42" | 1.17" | 0.17" | 1/4" | 1.07" | 0.13" | 0.16" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 43 | 2.2 | 6 | 1.32" | 1.07" | 0.167" | 1/4" | 0.97" | 0.093" | 0.155" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 55 | 7 | 18 | 1.42" | 1.17" | 0.167" | 1/4" | 1.07" | 0.125" | 0.155" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Crown Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 4.3 | 2.2 | 5.4 | 1.435" | 1.27" | 0.167" | 1/4" | 1.135" | 0.024" | 0.016" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 1.7 | 7 | 1.865" | 1.548" | 0.317" | 0.35" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 5 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.066" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30° Spear Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.025" | 2 | 0.5 | 1.6 | 1.17" | 1.01" | 0.107" | 0.16" | 1" | 0.016" | 0.009" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 0.6 | 2.5 | 0.66" | 0.56" | 0.07" | 0.1" | 0.52" | 0.03" | 0.02" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 5 | 2.4 | 5.6 | 1.36" | 1.12" | 0.167" | 1/4" | 1.09" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 3 | 1.5 | 3.8 | 0.67" | 0.55" | 0.07" | 0.1" | 0.49" | 0.04" | 0.03" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 10 | 1.7 | 7 | 1.45" | 1.13" | 0.317" | 0.35" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 12 | 2.2 | 5.5 | 0.97" | 0.89" | 0.107" | 0.16" | 0.73" | 0.054" | 0.04" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 23 | 2.2 | 7 | 1.3" | 1.22" | 0.167" | 1/4" | 0.97" | 0.08" | 0.059" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.156" | 5 | 2.8 | 7 | 1.33" | 1.07" | 0.17" | 1/4" | 0.97" | 0.09" | 0.08" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 5 | 2.8 | 16.4 | 1.42" | 1.17" | 0.17" | 1/4" | 1.07" | 0.13" | 0.094" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chisel Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 5 | 2.9 | 7 | 1.3" | 1.05" | 0.17" | 1/4" | 0.97" | 0.08" | 0.1" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90° Razor Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 4 | 1.8 | 6 | 1.585" | 1.268" | 0.317" | 0.4" | 1.135" | 0.024" | 0.016" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 4.3 | 2.2 | 5.4 | 1.435" | 1.27" | 0.167" | 1/4" | 1.135" | 0.024" | 0.016" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 3 | 2.4 | 7 | 1.7" | 1.45" | 0.167" | 1/4" | 1.43" | 0.031" | 0.021" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 11 | 2.7 | 7 | 1.3" | 1.05" | 0.167" | 1/4" | 1" | 0.04" | 0.026" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 14 | 2 | 7 | 1.46" | 1.14" | 0.317" | 0.35" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 17 | 2.6 | 6.5 | 1.31" | 1.06" | 0.167" | 1/4" | 1" | 0.054" | 0.036" | Gold Plated | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring Test Probe Sockets

Barrel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Min. Spacing Between Probe Ctr. | For Probe Barrel Lg. | For Mounting Hole Dia. | For Wire Ga. | Overall Lg. | Lg. | Dia. | Finish | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Disconnect-Terminal Jack | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" | 1.135" | 0.031" | 30, 28 | 1.235" | 1.235" | 0.032" | Gold Plated | 5 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 1.09" | 0.038" | 30, 28 | 1.262" | 1.095" | 0.038" | Nickel Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 1.43" | 0.038" | 30, 28 | 1.6" | 1.433" | 0.038" | Nickel Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Disconnect-Terminal Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 1.09" | 0.038" | 30, 28 | 1.262" | 1.095" | 0.038" | Nickel Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 1.43" | 0.038" | 30, 28 | 1.6" | 1.433" | 0.038" | Nickel Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Post-Terminal Wraparound Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 1.09" | 0.038" | 36, 32, 30 | 1.345" | 1.095" | 0.038" | Nickel Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 1.43" | 0.038" | 36, 32, 30 | 1.683" | 1.433" | 0.038" | Nickel Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 1" | 0.053" | 32, 30, 28, 26 | 1.499" | 1.07" | 0.052" | — | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 1" | 0.067" | 32, 30, 28, 26 | 1.509" | 1.08" | 0.066" | — | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.97" | 0.094" | 32, 30, 28, 26 | 1.509" | 1.08" | 0.093" | — | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Solder Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05" | 0.52" | 0.036" | 30, 29, 28 | 0.7" | 0.5" | 0.03" | Gold Plated | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 0.49" | 0.056" | 28, 27, 26, 25, 24 | 0.7" | 0.49" | 0.05" | Gold Plated | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | 1" | 0.053" | 28, 26, 24, 20 | 1.17" | 0.99" | 0.052" | — | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1" | 0.73" | 0.069" | 26, 25, 24, 23, 22 | 0.9" | 0.72" | 0.07" | — | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.97" | 0.095" | 26, 25, 24, 22 | 1.2" | 0.97" | 0.09" | — | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 0.97" | 0.095" | 20, 19, 18, 17, 16 | 1.2" | 0.97" | 0.09" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.156", 0.187" | 0.97" | 0.109" | 26, 25, 24, 22 | 1.22" | 1" | 0.11" | Gold Plated | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 0.97" | 0.109" | 20, 19, 18, 17, 16 | 1.2" | 0.97" | 0.11" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 1.07" | 0.142" | 26, 25, 24, 23, 22 | 1.3" | 1.1" | 0.14" | Gold Plated | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.187" | 1.07" | 0.142" | 20, 19, 18, 17, 16 | 1.31" | 1.06" | 0.14" | Gold Plated | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||