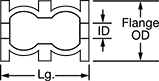

Flanged Compression Springs

Flanges on the ends of these springs provide a flat mounting surface. Springs are a polyester/rubber blend that is wear, oil, and fuel resistant.

As you squeeze a compression spring, it pushes back to return to its original length. Spring rate is the amount of force required for every inch of compression. The higher the spring rate, the harder it is to compress the spring.

Flange | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | OD | ID | OD | Thick. | Compressed Lg. @ Max. Load | Max. Load, lbs. | Spring Rate, lbs./in. | Material | Hardness | Temperature Range, °F | Each | |

| 3.438" | 1.5" | 1" | 1.9" | 0.2" | 1.85" | 200 | 103 | Polyester/Rubber Blend | Durometer 55D | -40° to 120° | 000000 | 000000 |

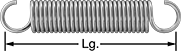

Extension Springs with Hook Ends

As you stretch an extension spring, it gets harder to pull. Minimum load is the amount of force required to start to extend the spring. Maximum load is the amount of force required to fully extend the spring. Spring rate is the amount of force required for every inch or mm of extension.

Load, lbs. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wire Dia. | Extended Lg. @ Max. Load | Min. | Max. | Spring Rate, lbs./in. | Material | Pkg. Qty. | Pkg. | |

3.438" Lg. | |||||||||

| 0.75" | 0.105" | 4.454" | 12.8 | 44.3 | 31 | Galvanized Spring-Tempered Steel | 6 | 0000000 | 00000 |