Extension Springs with Loop Ends

As you stretch an extension spring, it gets harder to pull. Minimum load is the amount of force required to start to extend the spring. Maximum load is the amount of force required to fully extend the spring. Spring rate is the amount of force required for every inch or millimeter of extension.

Load, lbs. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Wire Dia., mm | Extended Lg. @ Max. Load, mm | Min. | Max. | Spring Rate, lbs./mm | Material | Pkg. Qty. | Pkg. | |

38 mm Lg. | |||||||||

| 14 | 2 | 52.7 | 7.35 | 36.87 | 2.118 | Music-Wire Steel | 1 | 00000000 | 00000 |

Corrosion-Resistant Extension Springs with Hook Ends

Made of stainless steel, these springs are more corrosion resistant than steel springs. They're also easier to extend than steel springs. As you stretch an extension spring, it gets harder to pull. Minimum load is the amount of force required to start to extend the spring. Maximum load is the amount of force required to fully extend the spring. Spring rate is the amount of force required for every inch or millimeter of extension.

302 stainless steel springs have good corrosion resistance.

Load, lbs. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Wire Dia., mm | Extended Lg. @ Max. Load, mm | Min. | Max. | Spring Rate, lbs./mm | Material | Pkg. Qty. | Pkg. | |

38 mm Lg. | |||||||||

| 14 | 2 | 52.7 | 7.35 | 30.71 | 1.76 | 302 Stainless Steel | 1 | 00000000 | 000000 |

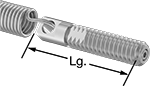

Extension Spring Stud Anchors

A black-oxide finish provides these steel anchors with mild corrosion resistance. Attach an extension spring to a stud and then thread the stud into your part for a secure connection.

Thread | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Min. Lg., mm | Lg., mm | Dia., mm | Hole Dia., mm | Material | Each | |

| M8 | 1.25 | 25 | 38 | 8 | 5 | Black-Oxide Steel | 0000000 | 00000 |

Corrosion-Resistant Extension Spring Stud Anchors

These stainless steel anchor studs offer excellent corrosion resistance. Attach an extension spring to a stud and then thread the stud into your part for a secure connection.

Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Min. Lg., mm | Lg., mm | Dia., mm | Hole Dia., mm | Material | Anchor Type | Each | |

| M8 | 1.25 | 25 | 38 | 8 | 5 | 18-8 Stainless Steel | Stud | 000000000 | 000000 |

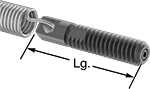

Swiveling Extension Spring Stud Anchors

A black-oxide finish provides these steel anchors with mild corrosion resistance. The head swivels 360° so the spring stays straight and properly coiled. Attach an extension spring to a stud and then thread the stud into your part for a secure connection. To make tightening easier, anchors have a hex socket on the bottom and wrench flats at the top of the threads.

Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Min. Lg., mm | Lg., mm | Dia., mm | Hole Dia., mm | Hex Size, mm | Material | Each | |

| M8 | 1.25 | 25 | 38 | 8 | 5 | 2.5 | Black-Oxide Steel | 000000000 | 000000 |

Corrosion-Resistant Swiveling Extension Spring Stud Anchors

These stainless steel anchor studs offer excellent corrosion resistance. The head swivels 360° so the spring stays straight and properly coiled. Attach an extension spring to a stud and then thread the stud into your part for a secure connection. To make tightening easier, anchors have a hex socket on the bottom and wrench flats at the top of the threads.

Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Min. Lg., mm | Lg., mm | Dia., mm | Hole Dia., mm | Hex Size, mm | Material | Each | |

| M8 | 1.25 | 25 | 38 | 8 | 5 | 2.5 | 18-8 Stainless Steel | 000000000 | 000000 |

Metric Color-Coded Die Springs

The colors and sizes of these springs follow ISO 10243 for metric die springs. Made of chrome-silicon steel, they have high tensile strength for reliable, long-lasting operation in repetitive applications, such as punching and stamping. All have closed and ground ends, which provide a flat mounting surface for even movement and distribution of loads.

Deflection is the distance the spring compresses, expressed as a percentage of its length.

As you squeeze a die spring, it gets harder to push. Spring rate is the amount of force required for every millimeter of compression. The higher the spring rate, the harder it is to compress the spring.

Wire | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., mm | Thick., mm | Wd., mm | Compressed Lg. @ Max. Load, mm | Deflection @ Max. Load | Max. Load, lbs. | Spring Rate, lbs./mm | Material | End Type | Each | |

Green (Light Load Rating) | ||||||||||

For 10 mm Hole Dia. (For 5 mm Shaft Dia.) | ||||||||||

| 38 | 0.99 | 1.78 | 24.7 | 35% | 20 | 1.5 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 00000 |

For 12.5 mm Hole Dia. (For 6 mm Shaft Dia.) | ||||||||||

| 38 | 1.32 | 2.36 | 24.7 | 35% | 40 | 3 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 16 mm Hole Dia. (For 8 mm Shaft Dia.) | ||||||||||

| 38 | 1.75 | 2.77 | 24.7 | 35% | 57 | 4.3 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 20 mm Hole Dia. (For 10 mm Shaft Dia.) | ||||||||||

| 38 | 1.91 | 4.19 | 24.7 | 35% | 99 | 7.4 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 25 mm Hole Dia. (For 12.5 mm Shaft Dia.) | ||||||||||

| 38 | 2.54 | 5.46 | 24.7 | 35% | 185 | 13.9 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 32 mm Hole Dia. (For 16 mm Shaft Dia.) | ||||||||||

| 38 | 2.92 | 7.24 | 24.7 | 35% | 281 | 21 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

Blue (Medium Load Rating) | ||||||||||

For 10 mm Hole Dia. (For 5 mm Shaft Dia.) | ||||||||||

| 38 | 1.17 | 1.85 | 26.6 | 30% | 30 | 2.6 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 12.5 mm Hole Dia. (For 6 mm Shaft Dia.) | ||||||||||

| 38 | 1.55 | 2.39 | 26.6 | 30% | 54 | 4.8 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 16 mm Hole Dia. (For 8 mm Shaft Dia.) | ||||||||||

| 38 | 2.06 | 3.12 | 26.6 | 30% | 86 | 7.6 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 20 mm Hole Dia. (For 10 mm Shaft Dia.) | ||||||||||

| 38 | 2.36 | 3.96 | 26.6 | 30% | 143 | 12.5 | Chrome-Silicon Steel | Closed and Ground | 0000000 | 0000 |

For 25 mm Hole Dia. (For 12.5 mm Shaft Dia.) | ||||||||||

| 38 | 2.92 | 5.54 | 26.6 | 30% | 238 | 20 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 32 mm Hole Dia. (For 16 mm Shaft Dia.) | ||||||||||

| 38 | 3.96 | 7.14 | 26.6 | 30% | 474 | 41 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 00000 |

Red (Heavy Load Rating) | ||||||||||

For 10 mm Hole Dia. (For 5 mm Shaft Dia.) | ||||||||||

| 38 | 1.37 | 1.83 | 28.5 | 25% | 36 | 3.8 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 20 mm Hole Dia. (For 10 mm Shaft Dia.) | ||||||||||

| 38 | 3.18 | 4.19 | 28.5 | 25% | 275 | 29 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 25 mm Hole Dia. (For 12.5 mm Shaft Dia.) | ||||||||||

| 38 | 4.01 | 5.61 | 28.5 | 25% | 467 | 49 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 32 mm Hole Dia. (For 16 mm Shaft Dia.) | ||||||||||

| 38 | 5.08 | 7.26 | 28.5 | 25% | 828 | 87 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 00000 |

Yellow (Extra Heavy Load Rating) | ||||||||||

For 10 mm Hole Dia. (For 5 mm Shaft Dia.) | ||||||||||

| 38 | 1.50 | 2.03 | 30.4 | 20% | 40 | 5.3 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 12.5 mm Hole Dia. (For 6 mm Shaft Dia.) | ||||||||||

| 38 | 2.13 | 2.46 | 30.4 | 20% | 61 | 8 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 16 mm Hole Dia. (For 8 mm Shaft Dia.) | ||||||||||

| 38 | 2.79 | 3.20 | 30.4 | 20% | 123 | 16.2 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 20 mm Hole Dia. (For 10 mm Shaft Dia.) | ||||||||||

| 38 | 4.09 | 4.06 | 30.4 | 20% | 302 | 39 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 0000 |

For 25 mm Hole Dia. (For 12.5 mm Shaft Dia.) | ||||||||||

| 38 | 4.95 | 5.49 | 30.4 | 20% | 591 | 77 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 00000 |

For 32 mm Hole Dia. (For 16 mm Shaft Dia.) | ||||||||||

| 38 | 6.20 | 7.32 | 30.4 | 20% | 902 | 118 | Chrome-Silicon Steel | Closed and Ground | 00000000 | 00000 |