Filter by

Roller Chain Trade Number

Shaft Diameter

OD

Hub Diameter

Shaft Type

Material

Component

Chain Type

Overall Width

Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Specifications Met

Sprockets

|

For Double Strand |

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 12 | 42 mm | Plain | 10 mm to 16 mm | 3571N101 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 14 | 48 mm | Plain | 10 mm to 18 mm | 3571N103 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 15 | 51 mm | Plain | 10 mm to 20 mm | 3571N104 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 16 | 54 mm | Plain | 12 mm to 20 mm | 3571N105 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 17 | 57 mm | Plain | 12 mm to 24 mm | 3571N106 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 18 | 60 mm | Plain | 12 mm to 25 mm | 3571N107 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 19 | 63 mm | Plain | 12 mm to 28 mm | 3571N108 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 20 | 66 mm | Plain | 12 mm to 30 mm | 3571N109 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 21 | 69 mm | Plain | 12 mm to 30 mm | 3571N11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 25 | 82 mm | Plain | 12 mm to 40 mm | 3571N114 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 27 | 88 mm | Plain | 12 mm to 45 mm | 3571N116 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 30 | 97 mm | Plain | 12 mm to 52 mm | 3571N119 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 12 | 56 mm | Plain | 12 mm to 23 mm | 3571N136 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 16 | 72 mm | Plain | 14 mm to 33 mm | 3571N14 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 17 | 76 mm | Plain | 14 mm to 36 mm | 3571N141 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 18 | 81 mm | Plain | 14 mm to 38 mm | 3571N142 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 20 | 89 mm | Plain | 14 mm to 40 mm | 3571N144 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 21 | 93 mm | Plain | 16 mm to 45 mm | 3571N145 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 26 | 113 mm | Plain | 20 mm to 56 mm | 3571N15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 30 | 129 mm | Plain | 20 mm to 64 mm | 3571N154 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 36 | 153 mm | Plain | 20 mm to 73 mm | 3571N157 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 38 | 161 mm | Plain | 20 mm to 73 mm | 3571N158 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 42 | 177 mm | Plain | 20 mm to 73 mm | 3571N16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12B-2 | ISO | 3/4" | 15 | 103 mm | Plain | 16 mm to 45 mm | 3571N209 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12B-2 | ISO | 3/4" | 17 | 115 mm | Plain | 20 mm to 54 mm | 3571N211 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12B-2 | ISO | 3/4" | 19 | 127 mm | Plain | 20 mm to 62 mm | 3571N213 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 12 | 1 5/8" | Plain | 1/2" to 9/16" | 2784K1 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 13 | 1 3/4" | Plain | 1/2" to 11/16" | 2784K2 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 14 | 1 7/8" | Plain | 1/2" to 7/8" | 2784K3 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 15 | 2" | Plain | 1/2" to 15/16" | 2784K4 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 16 | 2 1/8" | Plain | 1/2" to 15/16" | 2784K5 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 17 | 2 1/4" | Plain | 1/2" to 1 1/16" | 2784K6 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 18 | 2 3/8" | Plain | 1/2" to 1 3/16" | 2784K7 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 19 | 2 1/2" | Plain | 1/2" to 1 5/16" | 2784K8 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 20 | 2 9/16" | Plain | 3/4" to 1 5/16" | 2784K9 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 11 | 2" | Plain | 1/2" to 3/4" | 2784K16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 12 | 2 3/16" | Plain | 1/2" to 15/16" | 2784K17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 13 | 2 5/16" | Plain | 1/2" to 1" | 2784K18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 14 | 2 1/2" | Plain | 1/2" to 1 1/8" | 2784K19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 15 | 2 5/8" | Plain | 1/2" to 1 1/4" | 2784K21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 16 | 2 13/16" | Plain | 5/8" to 1 3/8" | 2784K22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 17 | 3" | Plain | 5/8" to 1 7/16" | 2784K23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 18 | 3 1/8" | Plain | 5/8" to 1 1/2" | 2784K24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 19 | 3 5/16" | Plain | 5/8" to 1 3/4" | 2784K25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 20 | 3 7/16" | Plain | 5/8" to 1 7/8" | 2784K26 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 11 | 2 1/2" | Plain | 5/8" to 15/16" | 2784K33 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 12 | 2 11/16" | Plain | 5/8" to 1 1/8" | 2784K34 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 13 | 2 15/16" | Plain | 5/8" to 1 5/16" | 2784K35 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 14 | 3 1/8" | Plain | 5/8" to 1 3/8" | 2784K36 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 15 | 3 5/16" | Plain | 3/4" to 1 1/2" | 2784K37 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 16 | 3 1/2" | Plain | 3/4" to 1 3/4" | 2784K38 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 17 | 3 3/4" | Plain | 3/4" to 1 7/8" | 2784K39 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 18 | 3 15/16" | Plain | 3/4" to 1 15/16" | 2784K41 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 19 | 4 1/8" | Plain | 1" to 2 1/8" | 2784K42 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 20 | 4 5/16" | Plain | 1" to 2 1/4" | 2784K43 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 11 | 3" | Plain | 1" to 1 1/4" | 2784K49 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 12 | 3 1/4" | Plain | 1" to 1 7/16" | 2784K51 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 13 | 3 1/2" | Plain | 1" to 1 1/2" | 2784K52 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 14 | 3 3/4" | Plain | 1" to 1 3/4" | 2784K53 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 15 | 4" | Plain | 1" to 1 7/8" | 2784K54 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 16 | 4 1/4" | Plain | 1" to 2" | 2784K55 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 17 | 4 7/16" | Plain | 1" to 2 1/4" | 2784K56 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 18 | 4 11/16" | Plain | 1" to 2 3/8" | 2784K57 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 19 | 4 15/16" | Plain | 1" to 2 1/2" | 2784K58 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 20 | 5 3/16" | Plain | 1" to 2 1/2" | 2784K59 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Taper-Lock Bushing-Bore Sprockets

|  |

Sprocket Shown with Bushing (Sold Separately) | For Double Strand |

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD | For Bushing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 30 | 5 1/16" | 2012 | 5507N19 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 36 | 6" | 2012 | 5507N21 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 30 | 6 5/16" | 2517 | 5507N32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 36 | 7 1/2" | 2517 | 5507N33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 30 | 7 9/16" | 2517 | 5507N45 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 36 | 9" | 2517 | 5507N46 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 15 | 2 5/8" | 1008 | 5507N11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 16 | 2 13/16" | 1008 | 5507N12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 17 | 3" | 1008 | 5507N13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 18 | 3 1/8" | 1210 | 5507N14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 19 | 3 5/16" | 1210 | 5507N15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 20 | 3 7/16" | 1610 | 5507N16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 21 | 3 11/16" | 1610 | 5507N17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 25 | 4 1/4" | 2012 | 5507N18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 14 | 3 1/8" | 1008 | 5507N22 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 15 | 3 5/16" | 1210 | 5507N23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 16 | 3 1/2" | 1210 | 5507N24 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 17 | 3 3/4" | 1610 | 5507N25 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 18 | 3 15/16" | 1610 | 5507N26 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 19 | 4 1/8" | 1610 | 5507N27 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 20 | 4 5/16" | 2012 | 5507N28 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 21 | 4 1/2" | 2012 | 5507N29 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 25 | 5 5/16" | 2012 | 5507N31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 13 | 3 1/2" | 1215 | 5507N34 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 14 | 3 3/4" | 1215 | 5507N35 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 15 | 4" | 1615 | 5507N36 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 16 | 4 1/4" | 1615 | 5507N37 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 17 | 4 7/16" | 1615 | 5507N38 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 18 | 4 11/16" | 2012 | 5507N39 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 19 | 4 15/16" | 2012 | 5507N41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 20 | 5 3/16" | 2517 | 5507N42 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 21 | 5 7/16" | 2517 | 5507N43 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 25 | 6 3/8" | 2517 | 5507N44 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Idler Sprockets

For Double Strand

|

Ball Bearing |

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | For Shaft Dia. | OD | Bearing Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 19 | 1/2" | 2 1/2" | Steel | 6260K1 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 19 | 5/8" | 2 1/2" | Steel | 6260K2 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 18 | 1/2" | 3 1/8" | Steel | 6260K3 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 18 | 5/8" | 3 1/8" | Steel | 6260K4 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 17 | 1/2" | 3 3/4" | Steel | 6260K5 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 17 | 5/8" | 3 3/4" | Steel | 6260K6 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 15 | 1/2" | 4" | Steel | 6260K7 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 15 | 5/8" | 4" | Steel | 6260K8 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80-2 | ANSI | 1" | 12 | 3/4" | 4 5/16" | Steel | 6260K9 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Roller Chain and Links

Chain | Connecting Links | Adding Links | Adding-and-Connecting Links | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

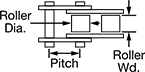

Trade No. | Std. | Pitch | Roller Dia. | Roller Wd. | Working Load, lb. | Per Ft. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35-2 | ANSI | 3/8" | 0.200" | 3/16" | 810 | 6261K711 | 000000 | 6261K221 | 00000 | 6261K103 | 00000 | 6261K841 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 0.312" | 5/16" | 1,350 | 6261K712 | 00000 | 6261K223 | 0000 | 6261K104 | 0000 | 6261K842 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 0.400" | 3/8" | 2,350 | 6261K713 | 00000 | 6261K224 | 0000 | 6261K109 | 0000 | 6261K843 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 0.469" | 1/2" | 3,300 | 6261K714 | 00000 | 6261K225 | 0000 | 6261K116 | 0000 | 6261K844 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80-2 | ANSI | 1" | 0.625" | 5/8" | 5,600 | 6261K715 | 00000 | 6261K226 | 00000 | 6261K117 | 00000 | 6261K845 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100-2 | ANSI | 1 1/4" | 0.750" | 3/4" | 8,600 | 6261K91 | 00000 | 6261K922 | 00000 | 6261K118 | 00000 | 6261K923 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120-2 | ANSI | 1 1/2" | 0.875" | 1" | 11,500 | 6261K81 | 00000 | 6261K706 | 00000 | ——— | 0 | 6261K92 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140-2 | ANSI | 1 3/4" | 1.000" | 1" | 15,300 | 6261K82 | 000000 | 6261K707 | 00000 | ——— | 0 | 6261K709 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160-2 | ANSI | 2" | 1.125" | 1 1/4" | 20,200 | 6261K83 | 000000 | 6261K708 | 00000 | ——— | 0 | 6261K94 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B-2 | ISO | 3/8" | 0.250" | 0.225" | 650 | 6027K11 | 00000 | 6027K1 | 0000 | ——— | 0 | 6027K5 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 0.335" | 0.305" | 1,200 | 6027K12 | 00000 | 6027K2 | 0000 | ——— | 0 | 6027K6 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10B-2 | ISO | 5/8" | 0.400" | 0.380" | 1,800 | 6027K13 | 00000 | 6027K3 | 0000 | ——— | 0 | 6027K7 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12B-2 | ISO | 3/4" | 0.475" | 0.460" | 2,600 | 6027K31 | 00000 | 6027K4 | 0000 | ——— | 0 | 6027K8 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 0.312" | 5/16" | 1,350 | 2331K1 | 00000 | 2331K11 | 0000 | ——— | 0 | 2331K12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 0.400" | 3/8" | 2,350 | 2331K2 | 00000 | 2331K13 | 0000 | ——— | 0 | 2331K14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 0.469" | 1/2" | 3,300 | 2331K3 | 00000 | 2331K15 | 0000 | ——— | 0 | 2331K16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80-2 | ANSI | 1" | 0.625" | 5/8" | 5,600 | 2331K4 | 00000 | 2331K17 | 00000 | ——— | 0 | 2331K18 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 0.335" | 0.305" | 1,200 | 1222N5 | 00000 | 1222N951 | 0000 | ——— | 0 | 1222N953 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10B-2 | ISO | 5/8" | 0.400" | 0.380" | 1,800 | 1222N6 | 00000 | 1222N961 | 0000 | ——— | 0 | 1222N963 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12B-2 | ISO | 3/4" | 0.475" | 0.460" | 2,600 | 1222N7 | 00000 | 1222N971 | 0000 | ——— | 0 | 1222N973 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16B-2 | ISO | 1" | 0.625" | 0.670" | 4,800 | 1222N8 | 00000 | 1222N981 | 00000 | ——— | 0 | 1222N983 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 0.312" | 5/16" | 190 | 2327K1 | 00000 | 2327K11 | 00000 | ——— | 0 | 2327K12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 0.400" | 3/8" | 300 | 2327K2 | 00000 | 2327K21 | 00000 | ——— | 0 | 2327K22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 0.469" | 1/2" | 460 | 2327K3 | 00000 | 2327K31 | 00000 | ——— | 0 | 2327K32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ANSI Roller Chain Spring Clips

Heavy Duty Roller Chain and Links

Chain | Connecting Links | Adding-and-Connecting Links | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trade No. | Std. | Pitch | Roller Dia. | Roller Wd. | Working Load, lb. | Per Ft. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50H-2 | ANSI | 5/8" | 0.400" | 3/8" | 2,400 | 5871K3 | 000000 | 5871K13 | 00000 | 5871K33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60H-2 | ANSI | 3/4" | 0.469" | 1/2" | 3,400 | 5871K4 | 00000 | 5871K14 | 0000 | 5871K34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80H-2 | ANSI | 1" | 0.625" | 5/8" | 5,800 | 5871K5 | 00000 | 5871K15 | 0000 | 5871K35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||