Filter by

Roller Chain Trade Number

Shaft Diameter

Number of Teeth

Chain Type

Hub Diameter

Component

Overall Width

Width

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Sprockets

For Roller Chain | Keyway | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Wd. | Dp. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 11 | 1" | Finished | 1/4" | — | — | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 11 | 1" | Finished | 3/8" | 3/32" | 3/64" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 11 | 1" | Plain | 1/4" to 5/16" | — | — | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 3/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Plain | 3/8" to 9/16" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 1" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Plain | 1/2" to 7/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 11 | 2" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 11 | 2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 11 | 2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 11 | 2" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Plain | 5/8" to 1" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Plain | 3/4" to 1 5/16" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 3/8" | 5/16" | 5/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 7/16" | 3/8" | 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 1/2" | 3/8" | 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 5/8" | 3/8" | 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Plain | 1" to 1 5/8" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Finished | 1" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Finished | 1 3/8" | 5/16" | 5/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Finished | 1 1/2" | 3/8" | 3/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Finished | 1 3/4" | 3/8" | 3/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Finished | 2" | 1/2" | 1/4" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 5" | Plain | 1" to 2 1/4" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | ANSI | 1 1/2" | 11 | 6" | Plain | 1 3/8" to 2 3/8" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | ANSI | 1 3/4" | 11 | 7" | Plain | 1 1/2" to 2 3/4" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | ANSI | 2" | 11 | 8" | Plain | 1 1/2" to 3 1/4" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 04B | ISO | 6 mm | 11 | 24 mm | Plain | 6 mm to 8 mm | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 05B | ISO | 8 mm | 11 | 32 mm | Plain | 8 mm to 11 mm | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B | ISO | 3/8" | 11 | 37 mm | Plain | 8 mm to 14 mm | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B | ISO | 1/2" | 11 | 51 mm | Plain | 10 mm to 22 mm | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10B | ISO | 5/8" | 11 | 66 mm | Plain | 12 mm to 25 mm | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12B | ISO | 3/4" | 11 | 79 mm | Plain | 12 mm to 32 mm | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 3/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 11 | 2 1/2" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 11 | 3" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 3/8" | 5/16" | 5/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 7/16" | 3/8" | 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 1/2" | 3/8" | 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 11 | 4" | Finished | 1 5/8" | 3/8" | 3/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 3/8" | 3/32" | 3/64" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 1/2" | 1/8" | 1/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 11 | 1 1/2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 1/2" | 1/8" | 1/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 11 | 2" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-2 | ANSI | 1/2" | 11 | 2" | Plain | 1/2" to 3/4" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-2 | ANSI | 5/8" | 11 | 2 1/2" | Plain | 5/8" to 15/16" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-2 | ANSI | 3/4" | 11 | 3" | Plain | 1" to 1 1/4" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Triple Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40-3 | ANSI | 1/2" | 11 | 2" | Plain | 1/2" to 3/4" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50-3 | ANSI | 5/8" | 11 | 2 1/2" | Plain | 5/8" to 15/16" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60-3 | ANSI | 3/4" | 11 | 3" | Plain | 1" to 1 1/4" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80-3 | ANSI | 1" | 11 | 4" | Plain | 1" to 1 3/4" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Idler Sprockets

For Single Strand

|

Ball Bearing |

|

Needle-Roller Bearing |

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | For Shaft Dia. | OD | Bearing Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 3/4" | 5" | Steel | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Needle-Roller Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 11 | 1 1/2" | 5" | Bronze | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | ANSI | 1 1/2" | 11 | 1 1/2" | 6" | Bronze | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | ANSI | 1 3/4" | 11 | 1 1/2" | 7" | Bronze | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Sprockets

Sprockets for Clog-Resistant Flat-Edge Roller Chain

|

For Roller Chain Trade No. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 11 | 9 7/8" | Plain | 1 1/4" to 3 7/16" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Spur Gears

Gears

Hub | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Pitch | No. of Teeth | Gear Pitch Dia. | OD | Face Wd. | Dia. | Wd. | Bore Type | For Shaft Dia. | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 1/2° Pressure Angle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 11 | 0.55" | 0.65" | 3/8" | 0.406" | 0.375" | Round/Plain Bore | 1/4" to 5/16" | White | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

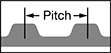

Gear Racks

|

14 1/2° Pressure Angle—Rectangular |

Gear Pitch | Lg., ft. | Pitch Ht. | Ht. | Face Wd. | Fabrication | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

14 1/2° Pressure Angle—Rectangular | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 4 | 0.325" | 3/8" | 3/8" | Machined | Green | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Timing Belt Pulleys

For Max. Belt Wd. | Pitch | No. of Teeth | Bore Type | For Shaft Dia. | Pitch Dia. | No. of Flanges | Hub Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For MXL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.080" | 11 | Finished | 1/8" | 0.28" | 1 | Standard | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.080" | 11 | Finished | 1/8" | 0.28" | 1 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 mm | 0.080" | 11 | Finished | 3 mm | 7.1 mm | 1 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For XL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 11 | Finished | 3/16" | 0.7" | 2 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 11 | Finished | 3/16" | 0.7" | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 11 | Finished | 1/4" | 0.7" | 2 | Flush | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 11 | Finished | 6 mm | 0.7" | 2 | Flush | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 11 | Finished | 6 mm | 0.7" | 2 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||