About Roller Chain and Sprockets

More

About Gears

More

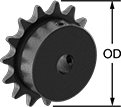

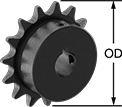

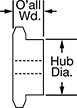

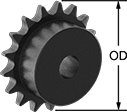

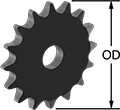

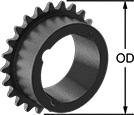

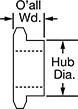

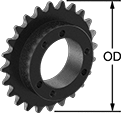

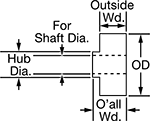

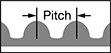

Sprockets for ANSI Roller Chain

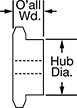

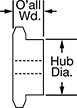

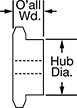

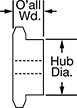

Mount these sprockets onto your shaft and secure with a set screw—no machining necessary.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

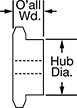

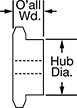

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 45 | 1/2" | 3.73" | 3/4" | 2" | __ | __ | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 5/8" | 3.73" | 3/4" | 2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 3/4" | 3.73" | 3/4" | 2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 7/8" | 3.73" | 3/4" | 2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1" | 3.73" | 3/4" | 2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/4" | 3.73" | 3/4" | 2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 3/8" | 3.73" | 3/4" | 2" | 5/16" | 5/32" | Steel | Two Set Screws | 00000000 | 00000 |

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 45 | 3/4" | 5.59" | 1" | 2 1/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 7/8" | 5.59" | 1" | 2 1/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/8" | 5.59" | 1" | 2 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 3/16" | 5.59" | 1" | 2 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/4" | 5.59" | 1" | 2 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 45 | 5/8" | 7.45" | 1 1/8" | 3 1/2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 3/4" | 7.45" | 1 1/8" | 3 1/2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 7/8" | 7.45" | 1 1/8" | 3 1/2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1" | 7.45" | 1 1/8" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/8" | 7.45" | 1 1/8" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 3/16" | 7.45" | 1 1/8" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/4" | 7.45" | 1 1/8" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 3/8" | 7.45" | 1 1/8" | 3 1/2" | 5/16" | 5/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 7/16" | 7.45" | 1 1/8" | 3 1/2" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/2" | 7.45" | 1 1/8" | 3 1/2" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 00000 |

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 45 | 3/4" | 7.45" | 1 1/16" | 3 1/2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1" | 7.45" | 1 1/16" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/4" | 7.45" | 1 1/16" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

| 45 | 1 1/2" | 7.45" | 1 1/16" | 3 1/2" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 00000 |

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 45 | 3/4" | 9.31" | 1 1/4" | 3 3/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 0000000 |

| 45 | 7/8" | 9.31" | 1 1/4" | 3 3/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1" | 9.31" | 1 1/4" | 3 3/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 1/8" | 9.31" | 1 1/4" | 3 3/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 3/16" | 9.31" | 1 1/4" | 3 3/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 1/4" | 9.31" | 1 1/4" | 3 3/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 3/8" | 9.31" | 1 1/4" | 3 3/4" | 5/16" | 5/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 7/16" | 9.31" | 1 1/4" | 3 3/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 1/2" | 9.31" | 1 1/4" | 3 3/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 5/8" | 9.31" | 1 1/4" | 3 3/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 3/4" | 9.31" | 1 1/4" | 3 3/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 15/16" | 9.31" | 1 1/4" | 3 3/4" | 1/2" | 1/4" | Steel | Two Set Screws | 00000000 | 000000 |

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 45 | 1" | 11.18" | 1 1/4" | 4 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 0000000 |

| 45 | 1 1/8" | 11.18" | 1 1/4" | 4 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 3/16" | 11.18" | 1 1/4" | 4 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 1/4" | 11.18" | 1 1/4" | 4 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 3/8" | 11.18" | 1 1/4" | 4 1/4" | 5/16" | 5/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 7/16" | 11.18" | 1 1/4" | 4 1/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 1/2" | 11.18" | 1 1/4" | 4 1/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 5/8" | 11.18" | 1 1/4" | 4 1/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 3/4" | 11.18" | 1 1/4" | 4 1/4" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 1 15/16" | 11.18" | 1 1/4" | 4 1/4" | 1/2" | 1/4" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 2" | 11.18" | 1 1/4" | 4 1/4" | 1/2" | 1/4" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 2 3/16" | 11.18" | 1 1/4" | 4 1/4" | 1/2" | 1/4" | Steel | Two Set Screws | 00000000 | 000000 |

| 45 | 2 7/16" | 11.18" | 1 1/4" | 4 1/4" | 5/8" | 5/16" | Steel | Two Set Screws | 00000000 | 000000 |

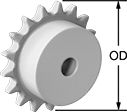

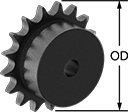

Machinable-Bore Sprockets for ANSI Roller Chain

For a custom fit on your shaft, these sprockets can be machined to your exact specifications. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

For technical drawings and 3-D models, click on a part number.

| Number of Teeth | For Shaft Dia. | For Max. Shaft Dia. | OD | Overall Wd. | Hub Dia. | Material | Each | |

For ANSI 25 Roller Chain (1/4" Pitch) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 45 | 1/2" | 1 3/8" | 3.73" | 3/4" | 2" | Steel | 0000000 | 000000 |

For ANSI 35 Roller Chain (3/8" Pitch) | ||||||||

| 45 | 5/8" | 1 1/2" | 5.59" | 1" | 2 1/4" | Steel | 00000000 | 00000 |

For ANSI 40 Roller Chain (1/2" Pitch) | ||||||||

| 45 | 3/4" | 2 3/8" | 7.45" | 1 1/8" | 3 1/2" | Steel | 00000000 | 00000 |

For ANSI 50 Roller Chain (5/8" Pitch) | ||||||||

| 45 | 3/4" | 2 1/2" | 9.31" | 1 1/4" | 3 3/4" | Steel | 00000000 | 00000 |

Lightweight Sprockets for ANSI Roller Chain

Made of nylon, these sprockets are lightweight, quiet, and corrosion resistant. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

| Number of Teeth | For Shaft Dia. | For Max. Shaft Dia. | OD | Overall Wd. | Hub Dia. | Material | Each | |

For ANSI 25 Roller Chain (1/4" Pitch) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 45 | 1/2" | 1" | 3.73" | 45/64" | 2" | Nylon Plastic | 00000000 | 000000 |

For ANSI 35 Roller Chain (3/8" Pitch) | ||||||||

| 45 | 1/2" | 1 3/4" | 5.59" | 1" | 2 3/8" | Nylon Plastic | 000000000 | 00000 |

For ANSI 40 Roller Chain (1/2" Pitch) | ||||||||

| 45 | 1" | 1 3/4" | 7.45" | 1 1/8" | 3 1/2" | Nylon Plastic | 00000000 | 000000 |

Flat Sprockets for ANSI Roller Chain

Also known as A-plate and weld sprockets, these have a slim profile that fits in narrow spaces and are often welded directly to a shaft.They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

| Number of Teeth | For Shaft Dia. | For Max. Shaft Dia. | OD | Overall Wd. | Material | Each | |

For ANSI 35 Roller Chain (3/8" Pitch) | |||||||

|---|---|---|---|---|---|---|---|

| 45 | 19/32" | 4 61/64" | 5.59" | 11/64" | Steel | 00000000 | 000000 |

For ANSI 40 Roller Chain (1/2" Pitch) | |||||||

| 45 | 23/32" | 6 39/64" | 7.45" | 9/32" | Steel | 0000000 | 00000 |

For ANSI 50 Roller Chain (5/8" Pitch) | |||||||

| 45 | 23/32" | 8 9/32" | 9.31" | 11/32" | Steel | 0000000 | 00000 |

For ANSI 60 Roller Chain (3/4" Pitch) | |||||||

| 45 | 15/16" | 9 15/16" | 11.18" | 15/32" | Steel | 0000000 | 000000 |

For ANSI 80 Roller Chain (1" Pitch) | |||||||

| 45 | 1 1/4" | 13 9/32" | 14.9" | 37/64" | Steel | 00000000 | 000000 |

Sprockets for Metric Roller Chain

Designed to meet ISO 606 and DIN 8187 international dimensional standards, these sprockets are for use with compatible ISO and DIN roller chain. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 06B Roller Chain (9.53 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 45 | 16 | 45 | 142.1 | 30 | 75 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

Taper-Lock Bushing-Bore Sprockets for ANSI Roller Chain

Get the same sizing versatility as quick-disconnect sprockets while using less space. The bushings for these sprockets mount flush inside the sprocket hub for a slim profile. The same sprocket can be used with different shaft diameters; choose a compatible taper-lock bushing with the bore size you need.

| Number of Teeth | For Bushing Style | OD | Overall Wd. | Hub Dia. | Material | Each | |

For ANSI 35 Roller Chain (3/8" Pitch) | |||||||

|---|---|---|---|---|---|---|---|

| 45 | 1610 | 5.588" | 1" | 3 1/4" | Steel | 0000000 | 000000 |

For ANSI 40 Roller Chain (1/2" Pitch) | |||||||

| 45 | 1610 | 7.451" | 1" | 3" | Steel | 0000000 | 000000 |

For ANSI 50 Roller Chain (5/8" Pitch) | |||||||

| 45 | 2012 | 9.313" | 1 1/4" | 3 9/16" | Steel | 0000000 | 000000 |

For ANSI 60 Roller Chain (3/4" Pitch) | |||||||

| 45 | 2012 | 11.175" | 1 1/4" | 3 9/16" | Steel | 00000000 | 000000 |

Quick-Disconnect (QD) Bushing-Bore Sprockets for ANSI Roller Chain

The same sprocket can be used with different shaft diameters; choose a compatible quick-disconnect bushing with the bore size you need.

| Number of Teeth | For Bushing Style | OD | Overall Wd. | Hub Dia. | Material | Each | |

For ANSI 35 Roller Chain (3/8" Pitch) | |||||||

|---|---|---|---|---|---|---|---|

| 45 | SH | 5.59" | 13/16" | 2 11/16" | Steel | 00000000 | 000000 |

For ANSI 40 Roller Chain (1/2" Pitch) | |||||||

| 45 | SDS | 7.45" | 3/4" | 3 3/16" | Steel | 00000000 | 00000 |

For ANSI 50 Roller Chain (5/8" Pitch) | |||||||

| 45 | SDS | 9.31" | 3/4" | 3 3/16" | Steel | 00000000 | 000000 |

For ANSI 60 Roller Chain (3/4" Pitch) | |||||||

| 45 | SF | 11.18" | 1 1/4" | 4 5/8" | Steel | 000000000 | 000000 |

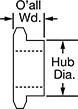

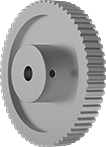

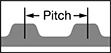

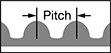

XL Series Corrosion-Resistant Timing Belt Pulleys

Pulleys are anodized aluminum, which is more corrosion resistant than steel. They are XL series (extra light) and have trapezoidal teeth. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Outside Wd. | Overall Wd. | Pitch Dia. | Fabrication | Material | Hub Dia. | Each | |

For 3/8" Max. Belt Wd. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

With Hub | ||||||||||||

| 2.845" | 45 | 0.200" | 3/8" | Finished | 0.563" | 1" | 2.865" | Machined | Anodized Aluminum | 1.5" | 0000000 | 000000 |

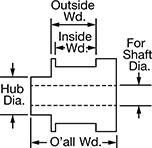

High-Strength GT Timing Belt Pulleys

For higher speed or higher torque applications, these GT series timing belt pulleys provide a more precise fit than HTD pulleys. Use them where accuracy is critical, such as in storage and retrieval systems or in robotics. Similar to HTD timing belt pulleys, their teeth are curved for high strength. The curved teeth create positive grip engagement with timing belts, so these pulleys do not require re-tensioning—unlike drives using V-belts or sheaves. And unlike chain drives, there’s no metal-on-metal contact, so these pulleys don’t require lubrication.

Anodized aluminum pulleys are lightweight and resist corrosion. They have a finished bore and come with set screws for mounting on shafts.

| Number of Teeth | Pitch, mm | For Shaft Diameter | Bore Type | Inside Width, mm | Outside Width, mm | Overall Width, mm | Pitch Diameter, mm | Number of Flanges | Fabrication | Material | Hub Diameter, mm | Each | |

For 9 mm Maximum Belt Width | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 45 | 3 | 1/4" | Finished | 10.16 | 13.46 | 21.16 | 42.977 | 2 | Machined | Anodized Aluminum | 31.75 | 00000000 | 000000 |

Ultra-High-Strength Poly Chain Timing Belt Pulleys

Curved teeth with a high pitch provide superior load distribution and reduce wear. They mount with a bushing for a more secure grip on the shaft than set screws. Bushing is not included. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Each | |

For 12 mm Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 124.46 | 45 | 8 | 2.75" | Finished | Taper-Lock Style 2012 | 14.48 | 21.59 | 31.75 | 115 | 2 | Machined | Black-Oxide Iron | 0000000 | 0000000 |

For 21 mm Max. Belt Wd. | ||||||||||||||

| 124.46 | 45 | 8 | 2.75" | Finished | Taper-Lock Style 2012 | 24.64 | 31.75 | 31.75 | 115 | 2 | Machined | Black-Oxide Iron | 0000000 | 000000 |

For 36 mm Max. Belt Wd. | ||||||||||||||

| 127.13 | 45 | 8 | 2.75" | Finished | Taper-Lock Style 2012 | 40.89 | 42.24 | 47.2 | 114.58 | 2 | Cast | Black-Oxide Iron | 00000000 | 000000 |

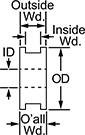

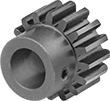

Metal Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Compared to plastic gears and racks, they’re better for high-load, high-speed, and heavy duty applications. Also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion. To minimize your footprint, mount one or more standard gears inside of an internal gear.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Carbon steel components have hard, strong, and wear-resistant teeth, although they will rust when exposed to moisture and corrosive chemicals. They're best for high-torque machines, like lifting equipment, and heavy duty applications, such as rock crushing. Gears with teeth that are not hardened can be hardened to fit your application.

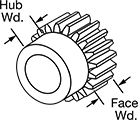

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Material | Teeth Heat Treatment | Dia., mm | Wd., mm | Set Screw Thread Size | Each | |

Round Bore | |||||||||||||

| 2 | 45 | 90 | 94 | 20 | 30 | 15 | Black-Oxide 1045 Carbon Steel | Not Hardened | 55 | 10 | __ | 00000000 | 000000 |

Round Bore with Set Screw | |||||||||||||

| 0.5 | 45 | 22.5 | 23.5 | 5 | 12 | 5 | Black-Oxide 1045 Carbon Steel | Not Hardened | 20 | 7 | M4 | 00000000 | 00000 |

| 0.8 | 45 | 36 | 37.6 | 8 | 16 | 6 | Black-Oxide 1045 Carbon Steel | Not Hardened | 28 | 8 | M4 | 00000000 | 00000 |

| 1 | 45 | 45 | 47 | 10 | 20 | 8 | Black-Oxide 1045 Carbon Steel | Not Hardened | 35 | 10 | M5 | 0000000 | 00000 |

| 1 | 45 | 45 | 47 | 10 | 20 | 8 | Black-Oxide 1045 Carbon Steel | Not Hardened | 35 | 10 | M5 | 00000000 | 00000 |

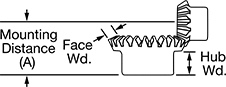

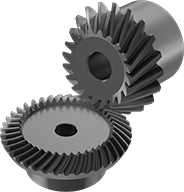

Metal Bevel Gears

A type of miter gear where one gear (sometimes called a pinion) is smaller than the other, bevel gears provide right-angle speed reduction at speed ratios ranging from 2:1 to 5:1. All are carbon steel for strength; they're compatible with plastic bevel gears. Teeth are not hardened so you can harden them to fit your application. Hardening a gear’s teeth increases its wear resistance.

A complete set consists of a gear and pinion (sold separately). For a gear and pinion to mesh correctly, they must have the same pressure angle, pitch/module, and face width. Speed ratio is the ratio by which shaft speed is reduced when transferring motion from pinion to gear. To increase shaft speed, transfer motion from gear to pinion. Changing shaft speed also changes torque: as speed decreases, torque increases.

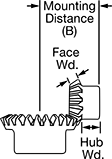

Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd., mm | Module | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Overall Wd., mm | For Shaft Dia., mm | Mounting Distance (A), mm | Dia., mm | Wd., mm | Material | Each | |

Round Bore | ||||||||||||||

| 6 | 1 | 20° | 3:1 | 45 | 45 | 45.4 | 12 | 8 | 17 | 30 | 5 | Black-Oxide 1045 Carbon Steel | 00000000 | 000000 |

| 10 | 1.5 | 20° | 3:1 | 45 | 68 | 68.1 | 20 | 10 | 28 | 36 | 11 | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 |

| 11 | 1.5 | 20° | 5:2 | 45 | 68 | 68.2 | 21 | 10 | 30 | 36 | 10 | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 |

Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd., mm | Module | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Overall Wd., mm | For Shaft Dia., mm | Mounting Distance (B), mm | Dia., mm | Wd., mm | Material | Each | |

Round Bore | ||||||||||||||

| 6 | 1 | 20° | 3:1 | 15 | 15 | 17.7 | 13 | 6 | 29 | 12 | 6 | Black-Oxide 1045 Carbon Steel | 00000000 | 000000 |

| 10 | 1.5 | 20° | 3:1 | 15 | 23 | 26.5 | 23 | 8 | 47 | 18 | 13 | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 |

| 11 | 1.5 | 20° | 5:2 | 18 | 27 | 30.9 | 22 | 8 | 45 | 23 | 10 | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 |

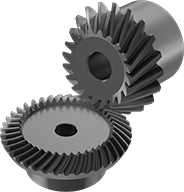

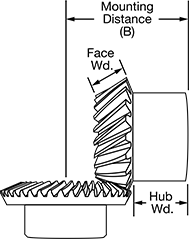

High-Power Metal Bevel Gears

Made from carbon steel with spiral teeth, these gears handle heavier loads at higher speeds than bevel gears with straight teeth because their teeth stay in contact longer. Their teeth engage gradually, which reduces vibration and noise, and they’re hardened for extra wear resistance. Use these gears to transmit motion at a right angle while changing shaft speed and torque. They reduce speeds at ratios of 2:1, 3:1, or 4:1. Customize their machinable bore to fit them on a variety of shafts. They’re also known as spiral bevel gears.

A complete set consists of a gear and pinion (sold separately). The gear is larger than the pinion, but for them to mesh correctly, they must have the same pressure angle, module, and face width.

Speed ratio is the ratio by which shaft speed is reduced when transferring motion from pinion to gear. To increase shaft speed, transfer motion from gear to pinion. Changing shaft speed also changes torque: as speed decreases, torque increases.

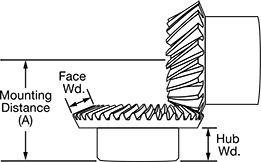

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Width, mm | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Overall Width, mm | For Shaft Diameter, mm | Mounting Distance (A), mm | Material | Diameter, mm | Width, mm | Each | |

Machinable Round Bore | |||||||||||||

| 15 | 20° | 3:1 | 45 | 90 | 90.67 | 30.3 | 12-30 | 40 | Black-Oxide 1045 Carbon Steel | 40 | 17 | 0000000 | 0000000 |

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Width, mm | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Overall Width, mm | For Shaft Diameter, mm | Mounting Distance (B), mm | Material | Diameter, mm | Width, mm | Each | |

Machinable Round Bore | |||||||||||||

| 15 | 20° | 3:1 | 15 | 30 | 34.78 | 29.7 | 10-14 | 60 | Black-Oxide 1045 Carbon Steel | 24 | 14 | 0000000 | 000000 |

Plastic Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Acetal gears are best suited for use in light duty machines or for prototyping.