Filter by

System of Measurement

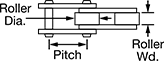

Pitch

Roller Chain Trade Number

Shaft Type

Bore Type

Material

Sprocket Type

DFARS Specialty Metals

Chain Type

Strand Type

Export Control Classification Number (ECCN)

Chain Style

Roller Width

Roller Diameter

Sprockets for Clog-Resistant Flat-Edge Roller Chain

|

Prevent jams with sprockets sized to grip our Clog-Resistant Flat-Edge Roller Chain. Their short teeth stay below the chain to avoid snagging conveyed items.

Sprocket teeth mesh with your roller chain to smoothly transmit power. These U.S.-made sprockets have machined teeth for a more precise fit than flame-cut or punched teeth, allowing them to glide in and out of the chain to reduce wear and extend chain life.

Steel—Steel is strong, but best for dry environments since moisture will cause it to rust.

Plain Bore—Plain bore sprockets give you options—machine a custom bore, weld, or press-fit them in place. They're sized to the minimum shaft diameter listed and are machinable up to the maximum.

For Roller Chain Trade No. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 8 | 7.3" | Plain | 15/16" to 3 1/4" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 9 | 8.18" | Plain | 1 1/4" to 3 7/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 10 | 9.03" | Plain | 1 1/4" to 3 7/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 11 | 9.9" | Plain | 1 1/4" to 3 7/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 12 | 10.75" | Plain | 1 1/4" to 3 7/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 13 | 11.63" | Plain | 1 1/4" to 3 3/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 14 | 12.43" | Plain | 1 1/4" to 3 3/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 15 | 13.25" | Plain | 1 1/2" to 3 3/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 17 | 14.96" | Plain | 1 1/2" to 3 3/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 19 | 16.64" | Plain | 1 1/2" to 4 1/2" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 21 | 18.31" | Plain | 1 1/2" to 4 1/2" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

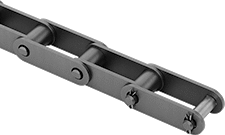

Clog-Resistant Flat-Edge Roller Chain and Links

|

Chain |

|

Connecting Links |

|

Adding Links |

|

Adding-and-Connecting Links |

|

Debris falls through this chain, so it doesn’t jam the rollers and bring everything to a halt. Originally designed to move lumber while letting splinters and sawdust drop to the floor, this chain has the largest roller spacing in our offering. Flat, oblong side plates create a level surface that keeps items moving along conveyor lines with no hang-ups. Unlike standard roller chain, there are no divots to snag products. Pair this chain with sprockets to transmit power between rotating shafts.

Lubrication is key to smooth operation and long chain life. Routinely apply oil by hand or install an oil dispenser for continuous lubrication.

Steel—The go-to for roller chain, steel is strong and economical. While proper lubrication helps prevent rusting, it’s not as corrosion resistant as coated or stainless steel.

Connecting Link—Use a single link to join both ends of your chain. Start by removing the spring clip from the link’s side plate. Then, slide the link pins into the mating rollers at each end of your chain and snap the clip back on. Also known as master links.

Adding Link—Attach with a connecting link to extend the length of your chain. Each link adds a length equal to the chain’s pitch. Also known as roller

links.

Adding-and-Connecting Link—An all-in-one link for adding and connecting. It adds a half-pitch length at the roller end, allowing finer length adjustments than full-pitch links. The pin end connects to your chain. Remove the side plate to install. Also known as half links and offset links.