Filter by

Strand Type

Roller Chain Trade Number

Pitch

Bore Type

Specifications Met

Chain Standard

Shaft Type

Chain Type

Material

Sprocket Type

Export Control Classification Number (ECCN)

RoHS

DFARS Specialty Metals

Chain Pitch Type

Chain Style

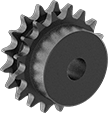

Sprockets

|

For Double Strand |

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD, mm | Bore Type | For Shaft Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 12 | 56 | Plain | 12 mm to 23 mm | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 16 | 72 | Plain | 14 mm to 33 mm | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 17 | 76 | Plain | 14 mm to 36 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 18 | 81 | Plain | 14 mm to 38 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 20 | 89 | Plain | 14 mm to 40 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 21 | 93 | Plain | 16 mm to 45 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 26 | 113 | Plain | 20 mm to 56 mm | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 30 | 129 | Plain | 20 mm to 64 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 36 | 153 | Plain | 20 mm to 73 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 38 | 161 | Plain | 20 mm to 73 mm | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 42 | 177 | Plain | 20 mm to 73 mm | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Roller Chain and Links

Roller Chain | Chain | Connecting Links | Adding-and-Connecting Links | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

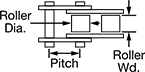

Trade No. | Std. | Pitch | Roller Dia. | Roller Wd. | Working Load, lb. | Per Ft. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 0.335" | 0.305" | 1,200 | 0000000 | 000000 | 000000 | 00000 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B-2 | ISO | 1/2" | 0.335" | 0.305" | 1,200 | 000000 | 00000 | 00000000 | 0000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||