About Gears

More

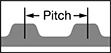

About Roller Chain and Sprockets

More

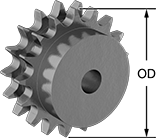

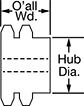

Sprockets for Double-Strand Metric Roller Chain

The double row of teeth on these sprockets are designed to fit into metric ISO double-strand roller chain. They have an unfinished bore that’s machined to the shaft diameter size listed. Machine them to fit any shaft up to the maximum shaft diameter size. The extended hub makes these sprockets more stable and more durable than flat sprockets. They meet ISO 606 (formerly DIN 8187), which is an international standard for sprocket and roller chain dimensions and materials.

For technical drawings and 3-D models, click on a part number.

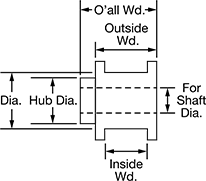

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 08B-2 Roller Chain (12.7 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 26 | 20 | 56 | 112.73 | 40 | 85 | Steel | DIN 8187, ISO 606 | 0000000 | 0000000 |

| 30 | 20 | 64 | 128.86 | 40 | 100 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 36 | 20 | 73 | 153.08 | 40 | 110 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 38 | 20 | 73 | 161.16 | 45 | 110 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 42 | 20 | 73 | 177.31 | 45 | 110 | Steel | DIN 8187, ISO 606 | 0000000 | 000000 |

For ISO 12B-2 Roller Chain (19.05 mm Pitch) | |||||||||

| 17 | 20 | 54 | 115.42 | 50 | 83 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

| 19 | 20 | 62 | 127.49 | 50 | 95 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

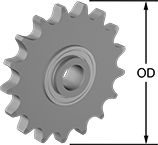

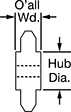

Idler Sprockets for Metric Roller Chain

Keep constant tension on your drive with these sprockets that press against your metric ISO roller chain to take up slack and reduce wear and vibration. They rotate freely on built-in ball bearings, which are double sealed to keep dirt out, and are for use with roller chain tensioners. All come with a finished bore that fits directly onto your shaft—no need for machining. These sprockets meet ISO 606, which is an international standard for dimensions and materials.

For technical drawings and 3-D models, click on a part number.

Bearing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Teeth | For Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Type | Material | Specifications Met | Each | |

For ISO 16B Roller Chain (25.4 mm Pitch) | ||||||||||

| 12 | 20 | 109 | 18 | 47 | Steel | Ball | Steel | ISO 606 | 000000 | 000000 |

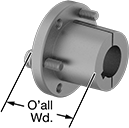

Taper-Lock Bushings

Mount these hubless bushings flush into your sprocket or pulley for a slim profile with no protruding screws. They are for use with taper-lock sprockets of the same bushing style. As you tighten the included set screws, the bushing grips the shaft and pulls it into your sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

1008 Style Bushing | |||||||||

| 20mm | 22mm | 6mm | 2.8mm | 8° | 55 | Steel | Set Screws | 000000000 | 000000 |

1108 Style Bushing | |||||||||

| 20mm | 22mm | 6mm | 2.8mm | 8° | 55 | Steel | Set Screws | 000000000 | 00000 |

1210 Style Bushing | |||||||||

| 20mm | 25mm | 6mm | 2.8mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

1610 Style Bushing | |||||||||

| 20mm | 25mm | 6mm | 2.8mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

1615 Style Bushing | |||||||||

| 20mm | 38mm | 6mm | 2.8mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

2012 Style Bushing | |||||||||

| 20mm | 32mm | 6mm | 2.8mm | 8° | 280 | Steel | Set Screws | 000000000 | 00000 |

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Steel | |||||||

H Style Bushing | |||||||

| 20mm | 1 1/4" | 6mm | 3mm | 3° | 95 | 00000000 | 000000 |

Quick-Grip Screw-Clamp Bushings

Also known as Trantorque bushings, these tighten with a twist of the collar nut—no screws needed. As you tighten the collar nut, the inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear.

For technical drawings and 3-D models, click on a part number.

Flanged Screw-Clamp Bushings

A mounting flange prevents movement during tightening. These bushings are good for shock loads. When you tighten the included screws, the bushing's inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. They can be mounted on shafts with or without keyways.

For technical drawings and 3-D models, click on a part number.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 20mm | 38mm | 30mm | 1,800 | 90 | Steel | Clamping Screws | 0000000 | 000000 |

Corrosion-Resistant Flanged Screw-Clamp Bushings

Made from stainless steel or plated with nickel, these bushings resist corrosion. A mounting flange prevents movement during tightening. As screw-clamp bushings, they're good for shock loads. When you tighten the clamping screws, the bushing's inner sleeve tightens onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear.

Nickel-plated steel bushings have good corrosion resistance in wet environments. However, the plating may begin to flake with long-term use.

Stainless steel bushings have excellent corrosion resistance and can withstand prolonged exposure to moisture.

For technical drawings and 3-D models, click on a part number.

Quick-Grip Flanged Hydraulic Bushings

Tighten just one set screw to clamp these bushings evenly around your shaft. The screw forces hydraulic fluid in between the double-walled sleeve, expanding the two walls against the shaft and the hub of your sprocket, pulley, or gear for a tight hold. Since you don’t have to tighten multiple screw clamps individually, these bushings are quick to adjust and more likely to stay aligned on your shaft. They’re also good for shock loads. A mounting flange prevents movement during tightening. Use a hex key to tighten.

Note: To avoid deforming the sleeve walls, make sure to fully tighten the screw.

Stainless steel bushings have excellent corrosion resistance in most environments.

For technical drawings and 3-D models, click on a part number.

Timing Belt Idler Pulleys

Add these free-spinning pulleys to your timing belt setup to minimize vibration and keep belts from wearing out. The needle bearing at the center of these pulleys is lined with small, cylindrical rollers that reduce friction as they rotate. This bearing allows both the pulley and the shaft it’s mounted on to spin independently. Made from iron or steel, these pulleys are strong and wear-resistant. The black oxide coating protects the pulleys from corrosion in dry environments.

Curved teeth have more surface contact with belts than traditional trapezoidal teeth, which allows you to apply more torque without damaging belts. These teeth fit together seamlessly to prevent backlash, or unwanted movement of the belt on the pulley, for a smooth, quiet cycle. They are also known as curvilinear belt pulleys.

For technical drawings and 3-D models, click on a part number.

| For Max. Belt Wd., mm | OD, mm | Number of Teeth | Teeth Shape | Pitch, mm | For Shaft Dia., mm | Dia., mm | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Bearing Type | Hub Dia., mm | Each | |

For GT Belt Trade Size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 90 | 32 | Curved | 8 | 20 | 80.12 | Plain | 20 | 31.5 | 46.23 | 81.48 | 2 | Machined | Black-Oxide Iron | Needle Roller | 69.85 | 0000000 | 0000000 |

For GT2 Belt Trade Size | ||||||||||||||||||

| 21 | 90 | 32 | Curved | 8 | 20 | 79.88 | Plain | 21 | 31.5 | 45.97 | 81.48 | 2 | Machined | Black-Oxide Iron | Needle Roller | 69.85 | 0000000 | 000000 |

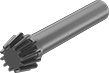

Metal Miter Gears

With straight, conically shaped teeth and a 1:1 speed ratio, miter gears connect two shafts at an angle without changing shaft speed or torque. They're more efficient than spiral miter gears because they create less friction.

For two gears to mesh correctly, they must have the same pressure angle, shaft angle, pitch/module, and number of teeth.

Carbon steel gears have hard, strong, and wear-resistant teeth. They’re best for heavy duty and high-torque applications, such as lifting equipment. However, these gears will rust when exposed to moisture or corrosive chemicals. Some gears have hardened teeth for additional wear resistance; gears with teeth that are not hardened can be hardened to fit your application.

For technical drawings and 3-D models, click on a part number.

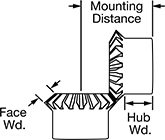

Hub | Keyway | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | For Shaft Angle | Pressure Angle | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Mounting Distance, mm | Teeth Heat Treatment | Dia., mm | Wd., mm | Wd., mm | Dp., mm | Set Screw Thread Size | Each | |

Keyed Bore with Set Screw—1045 Carbon Steel | |||||||||||||||||

| 2 | 30 | 90° | 20° | 60 | 62.8 | 12 | 29.4 | 20 | 50 | Hardened | 45 | 12.5 | 6 | 2.8 | M6 | 000000 | 000000 |

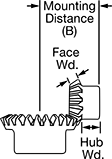

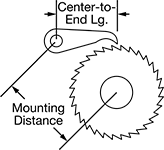

Metal Bevel Gears

A type of miter gear where one gear (sometimes called a pinion) is smaller than the other, bevel gears provide right-angle speed reduction at speed ratios ranging from 2:1 to 5:1. All are carbon steel for strength; they're compatible with plastic bevel gears. Teeth are not hardened so you can harden them to fit your application. Hardening a gear’s teeth increases its wear resistance.

A complete set consists of a gear and pinion (sold separately). For a gear and pinion to mesh correctly, they must have the same pressure angle, pitch/module, and face width. Shaft-mounted pinions come already securely fastened to a shaft.

Speed ratio is the ratio by which shaft speed is reduced when transferring motion from pinion to gear. To increase shaft speed, transfer motion from gear to pinion. Changing shaft speed also changes torque: as speed decreases, torque increases.

For technical drawings and 3-D models, click on a part number.

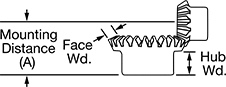

Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd., mm | Module | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Overall Wd., mm | For Shaft Dia., mm | Mounting Distance (A), mm | Dia., mm | Wd., mm | Material | Each | |

Round Bore | ||||||||||||||

| 20 | 2.5 | 20° | 5:1 | 60 | 150 | 150.5 | 40 | 20 | 50 | 70 | 20 | Black-Oxide 1045 Carbon Steel | 00000000 | 0000000 |

Shaft | Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd., mm | Module | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Overall Wd., mm | Dia., mm | Lg., mm | Mounting Distance (B), mm | Dia., mm | Wd., mm | Material | Each | |

| 20 | 2.5 | 20° | 5:1 | 12 | 30 | 37.1 | 143 | 20.2 | 115 | 83 | 25 | 8 | Black-Oxide 1045 Carbon Steel | 00000000 | 000000 |

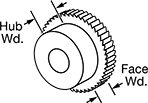

Metal Ratcheting Gears

Compared to plastic gears, these metal ratcheting gears are better for high-load, high-speed, and heavy duty applications. Used to prevent unwanted motion in jacks, tie downs, clutches, and winches, ratchet gears have sloped teeth that allow motion in one direction and prevent it in the other.

Gears with hardened teeth are more wear resistant than gears with teeth that are not hardened.

For technical drawings and 3-D models, click on a part number.

Hub | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd. | Number of Teeth | OD | For Shaft Dia. | Mounting Distance | Material | Teeth Heat Treatment | Overall Wd. | Dia. | Wd. | Each | |

Round Bore | |||||||||||

| 20mm | 40 | 120mm | 20mm | 85.2mm | 1045 Carbon Steel | Hardened | 20 mm | __ | __ | 0000000 | 0000000 |

| 20mm | 50 | 150mm | 20mm | 95.5mm | 1045 Carbon Steel | Hardened | 20 mm | __ | __ | 0000000 | 000000 |

| 25mm | 30 | 120mm | 20mm | 95.7mm | 1045 Carbon Steel | Hardened | 25 mm | __ | __ | 0000000 | 000000 |

| 25mm | 50 | 200mm | 20mm | 122.4mm | 1045 Carbon Steel | Hardened | 43 mm | 100 mm | 18 mm | 00000000 | 000000 |