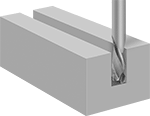

Spiral Router Bits for Steel and Stainless Steel

The aluminum-titanium-nitride (AlTiN) coating on these bits resists heat and wear when cutting steel and stainless steel. They have a square cut style for creating slots, pockets, and edges. They're made of solid carbide for longer tool life and faster cutting speeds than high-speed steel. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the bit from breaking. With spiral flutes, they leave a smoother finish than straight-flute bits and are good for making plunge cuts. The flutes lift chips up from the workpiece for applications that require a smooth finish on the bottom edge of the cut. Securely clamp your material before routing to prevent lifting. Bits with more flutes produce a smoother finish.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | Each | |

Aluminum Titanium Nitride (AlTiN) Coated Carbide | |||||||

|---|---|---|---|---|---|---|---|

Spiral Flutes with Upward Chip Removal | |||||||

| 1/32" | 1/16" | 1/8" | 1 1/2" | 4 | CNC Machine | 00000000 | 000000 |

| 1/16" | 3/16" | 1/8" | 1 1/2" | 2 | CNC Machine | 00000000 | 00000 |

| 1/16" | 3/16" | 1/8" | 1 1/2" | 4 | CNC Machine | 00000000 | 00000 |

| 1/8" | 1/4" | 1/8" | 2" | 2 | CNC Machine | 0000000 | 00000 |

| 1/8" | 3/8" | 1/4" | 1 1/2" | 3 | CNC Machine | 00000000 | 00000 |

| 1/8" | 3/8" | 1/4" | 1 1/2" | 4 | CNC Machine | 00000000 | 00000 |

| 3/16" | 3/8" | 3/16" | 2 1/2" | 2 | CNC Machine | 0000000 | 00000 |

| 3/16" | 7/16" | 1/4" | 1 7/8" | 3 | CNC Machine | 00000000 | 00000 |

| 1/4" | 3/8" | 1/4" | 2 1/2" | 2 | CNC Machine | 0000000 | 00000 |

| 1/4" | 5/8" | 1/4" | 2 3/8" | 3 | CNC Machine | 00000000 | 00000 |

| 1/4" | 5/8" | 1/4" | 2 3/8" | 4 | CNC Machine | 00000000 | 00000 |

| 1/4" | 1 1/8" | 1/4" | 3" | 4 | CNC Machine | 00000000 | 00000 |

| 5/16" | 1 1/8" | 5/16" | 3" | 2 | CNC Machine | 00000000 | 00000 |

| 3/8" | 1/2" | 3/8" | 3" | 2 | CNC Machine | 0000000 | 00000 |

| 1/2" | 3/4" | 1/2" | 3" | 2 | CNC Machine | 00000000 | 00000 |

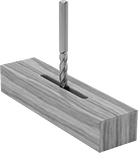

Drill/Rout Router Bits

Drill, rout, and trim with the same bit. The unique shape on these bits was originally used for aircraft panels. They have a pointed end and spiral flutes, like a drill bit, making downward plunge cuts easier than with square-cut and straight-flute bits. The spiral flutes also leave a smoother finish. The flutes lift chips up from the workpiece for applications that require a clean finish on the bottom edge of the cut. Securely clamp your material before routing to prevent lifting.

These bits are made of high-speed steel for general purpose use. They can be used with hand tools, router tables, and CNC machines. These bits do not have a pilot, so guide your router along a straight edge when hand routing to make accurate cuts.

Bits with four flutes produce a smoother finish than three-flute bits.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | For Use On | Each | |

Uncoated High-Speed Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

Spiral Flutes with Upward Chip Removal | ||||||||

| 3/32" | 13/16" | 3/32" | 2" | 3 | Hand Router, Router Table, CNC Machine | Cast Iron, Copper, Stainless Steel, Steel, Titanium | 00000000 | 000000 |

| 1/8" | 7/8" | 1/8" | 2 1/4" | 3 | Hand Router, Router Table, CNC Machine | Cast Iron, Copper, Stainless Steel, Steel, Titanium | 00000000 | 00000 |

| 5/32" | 1 1/16" | 3/16" | 2 1/2" | 3 | Hand Router, Router Table, CNC Machine | Cast Iron, Copper, Stainless Steel, Steel, Titanium | 00000000 | 00000 |

| 7/32" | 1 1/4" | 1/4" | 2 3/4" | 4 | Hand Router, Router Table, CNC Machine | Cast Iron, Copper, Stainless Steel, Steel, Titanium | 00000000 | 00000 |