How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Stainless Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a

Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides. Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting. Cap flanges are also known as blind flanges.

Forged flanges have better strength than cast flanges. Cast flanges are also called MSS flanges.

304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met: ASTM A182, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

Flanges | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bolt Hole | Thin-Wall Straight Adapters | Standard-Wall Straight Adapters | ||||||||||

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | Each | Each | |||

304/304L Stainless Steel | ||||||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| 8 | 13 1/2" | 3/4" | 7/8" | 8 | 11 3/4" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| 10 | 16" | 7/8" | 1" | 12 | 14 1/4" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000 | 00 |

| 12 | 19" | 7/8" | 1" | 12 | 17" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000 | 00 |

316/316L Stainless Steel | ||||||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| 8 | 13 1/2" | 3/4" | 7/8" | 8 | 11 3/4" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| 12 | 19" | 7/8" | 1" | 12 | 17" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000 | 00 |

- For Use With: Air, Water, Natural Gas, Oil

- Pressure Class: 150

- Specifications Met: MSS SP-51, ASTM A351

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

Bolt Hole | 304 Stainless Steel | 316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | Each | ||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 000000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 000000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

- For Use With: Air, Water, Natural Gas, Oil

- Pressure Class: 150

- Specifications Met: MSS SP-42, ASTM A351

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

Bolt Hole | 304 Stainless Steel | 316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | Each | ||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 000000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 |

High-Pressure Stainless Steel Unthreaded Pipe Flanges

Use these heavy duty forged flanges for high-pressure applications. Bolt two flat-surface flanges or two raised-surface flanges of same size together with a gasket (sold separately) to create an access point in a pipe line.

304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met:

Pressure Class 300: ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6

Pressure Class 600: ASME B16.5, ASTM A182 - Certification:: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

Flanges | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bolt Hole | Straight Adapters | |||||||||||

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | Each | ||

304/304L Stainless Steel | ||||||||||||

Pressure Class 300 | ||||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 00000000 | 000000 | 000000000 | 000000 |

| 1 | 16 | 600 psi @ 72° F | 300 psi @ 360° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | 00000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 24 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/8" | 3/4" | 0.875" | 4 | 4 1/2" | 00000000 | 000000 | 000000000 | 00000 |

| 2 | 32 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/2" | 5/8" | 0.75" | 8 | 5" | 00000000 | 000000 | 000000000 | 00000 |

| 2 1/2 | 40 | 600 psi @ 72° F | 300 psi @ 360° F | 7 1/2" | 3/4" | 0.875" | 8 | 5 7/8" | 00000000 | 000000 | 000000000 | 00000 |

| 3 | 48 | 600 psi @ 72° F | 300 psi @ 360° F | 8 1/4" | 3/4" | 0.875" | 8 | 6 5/8" | 00000000 | 000000 | 000000000 | 00000 |

| 4 | 64 | 600 psi @ 72° F | 300 psi @ 360° F | 10" | 3/4" | 0.875" | 8 | 7 7/8" | 00000000 | 000000 | 000000000 | 00000 |

| 6 | 96 | 600 psi @ 72° F | 300 psi @ 360° F | 12 1/2" | 3/4" | 0.875" | 12 | 10 5/8" | 00000000 | 000000 | 000000000 | 000000 |

Pressure Class 600 | ||||||||||||

| 1 | 16 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 64 | 1,200 psi @ 72° F | 840 psi @ 400° F | 10 3/4" | 7/8" | 1" | 8 | 8 1/2" | 0000000 | 000000 | 000000000 | 00000 |

316/316L Stainless Steel | ||||||||||||

Pressure Class 300 | ||||||||||||

| 1 | 16 | 600 psi @ 72° F | 300 psi @ 360° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | 00000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 24 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/8" | 3/4" | 0.875" | 4 | 4 1/2" | 00000000 | 000000 | 000000000 | 00000 |

| 2 | 32 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/2" | 5/8" | 0.75" | 8 | 5" | 00000000 | 000000 | 000000000 | 00000 |

| 2 1/2 | 40 | 600 psi @ 72° F | 300 psi @ 360° F | 7 1/2" | 3/4" | 0.875" | 8 | 5 7/8" | 00000000 | 000000 | 000000000 | 00000 |

| 3 | 48 | 600 psi @ 72° F | 300 psi @ 360° F | 8 1/4" | 3/4" | 0.875" | 8 | 6 5/8" | 00000000 | 000000 | 000000000 | 00000 |

High-Pressure Stainless Steel Unthreaded SAE Pipe Flanges

Create an access point in a high-pressure hydraulic fluid line with these flanges. They are also known as Code 61 SAE hydraulic flanges. To connect, bolt a flange with an O-ring groove surface to a flange with a flat surface of the same size. Flanges are 316 stainless steel for excellent corrosion resistance.

Socket-connect flanges weld to pipe for a strong, permanent connection. Cap flanges are also known as blind flanges.

- For Use With: Hydraulic Fluid

- Specifications Met: SAE J518, ISO 6162

Flange | Bolt Hole | 316/316L Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | SAE Flange Size | Dash Size | Max. Pressure | Ht. | Wd. | Dp. | Mounting Hardware Included | For Bolt Dia. | Dia. | No. of | Ctr.-to-Ctr. | Each | |

| 3/4 | 3/4 | 12 | 5,000 psi @ 72° F | 2 5/8" | 1 3/4" | 15/16" | No | 3/8" | 0.406" | 4 | 7/8", 1 7/8" | 0000000 | 0000000 |

| 1 | 1 | 16 | 5,000 psi @ 72° F | 2 53/64" | 2" | 15/16" | No | 3/8" | 0.406" | 4 | 1.031", 2.062" | 00000000 | 000000 |

| 1 1/2 | 1 1/2 | 24 | 3,000 psi @ 72° F | 3 3/4" | 2 3/4" | 1 3/16" | No | 1/2" | 0.531" | 4 | 1.406", 2 3/4" | 00000000 | 000000 |

| 2 | 2 | 32 | 3,000 psi @ 72° F | 4" | 3 1/4" | 1 7/16" | No | 1/2" | 0.531" | 4 | 1.688", 3.062" | 00000000 | 000000 |

- For Use With: Hydraulic Fluid

- Specifications Met: SAE J518, ISO 6162

Flange | Bolt Hole | 316/316L Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SAE Flange Size | Dash Size | Max. Pressure | Ht. | Wd. | Dp. | Mounting Hardware Included | For Bolt Dia. | Dia. | No. of | Ctr.-to-Ctr. | Each | |

| 2 | 32 | 3,000 psi @ 72° F | 4" | 3 1/4" | 1 45/64" | No | 1/2" | 0.531" | 4 | 1.688", 3.063" | 00000000 | 0000000 |

Low-Pressure Stainless Steel Threaded Pipe Flanges

Also known as Pressure Class 150 flanges, these are designed for low-pressure pipe applications. Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point within a line.

304 stainless steel flanges have very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance. Cast flanges are also called MSS flanges.

- For Use With: Natural Gas, Steam, Oil, Water, Air

- Pressure Class: 150

- Specifications Met: MSS SP-51, ASTM A351, MSS SP-42

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Class 150 stainless steel

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

304 Stainless Steel | |||||||||

NPT | |||||||||

| 1/2 | 3 1/2" | 1/2" | 0.625" | 4 | 2 3/8" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 0.625" | 4 | 2 3/4" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 0.625" | 4 | 3 1/8" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 0.625" | 4 | 3 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 0.625" | 4 | 3 7/8" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 2 | 6" | 5/8" | 0.75" | 4 | 4 3/4" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 2 1/2 | 7" | 5/8" | 0.75" | 4 | 5 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 0.75" | 4 | 6" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 4 | 9" | 5/8" | 0.75" | 8 | 7 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

316 Stainless Steel | |||||||||

NPT | |||||||||

| 1/2 | 3 1/2" | 1/2" | 0.625" | 4 | 2 3/8" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 3/4 | 3 7/8" | 1/2" | 0.625" | 4 | 2 3/4" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 0.625" | 4 | 3 1/8" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 0.625" | 4 | 3 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 0.625" | 4 | 3 7/8" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 2 | 6" | 5/8" | 0.75" | 4 | 4 3/4" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 2 1/2 | 7" | 5/8" | 0.75" | 4 | 5 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 0.75" | 4 | 6" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

| 4 | 9" | 5/8" | 0.75" | 8 | 7 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

High-Pressure Stainless Steel Threaded SAE Pipe Flanges

Also known as Code 61 SAE hydraulic flanges, these let you create an access point in a high-pressure hydraulic line. To connect, bolt flanges to equipment, or bolt a flange with an O-ring groove surface to a flange with a flat surface of the same size. Flanges are 316 stainless steel for excellent corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

- Specifications Met: SAE J518, ISO 6162

- For Use With: Hydraulic Fluid

Flange | Bolt Hole | 316/316L Stainless Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | SAE Flange Size | Dash Size | Max. Pressure | Ht. | Wd. | Dp. | Mounting Hardware Included | For Bolt Dia. | Dia. | No. of | Ctr.-to-Ctr. | Each | |

NPTF | ||||||||||||||

| 1 | __ | 1 | 16 | 2,000 psi @ 72° F | 2 53/64" | 2" | 1 29/64" | No | 3/8" | 0.312" | 4 | 1.031", 2.062" | 0000000 | 0000000 |

| 1 1/2 | __ | 1 1/2 | 24 | 1,000 psi @ 72° F | 3 3/4" | 2 3/4" | 1 45/64" | No | 1/2" | 0.422" | 4 | 1.406", 2.75" | 0000000 | 000000 |

| 2 | __ | 2 | 32 | 1,000 psi @ 72° F | 4" | 3 1/4" | 1 45/64" | No | 1/2" | 0.422" | 4 | 1.688", 3.062" | 0000000 | 000000 |

UN/UNF (SAE Straight) | ||||||||||||||

| __ | 2 1/2"-12 | 2 | 32 | 3,000 psi @ 72° F | 4" | 3 1/4" | 1 45/64" | No | 1/2" | 0.531" | 4 | 1.688", 3.062" | 0000000 | 000000 |

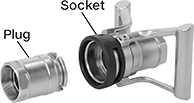

Minimal-Spill Push-and-Turn Hose Couplings for Chemicals

Quickly connect and disconnect hose lines used with a variety of chemicals, from adhesives to isopropyl alcohol and ink. Any part of these couplings that contacts fluid is made from 316 stainless steel, C-276 Hastelloy, PTFE, or fluoroelastomer to withstand the chemicals in your line. Tough enough to handle frequent use, these couplings are designed to be virtually spill free. Also known as dry disconnects and double-shut off couplings, both the plug and the socket have a shut-off valve that stops the flow of liquids when they’re separated. To connect, push the plug into the socket and lock with a quarter turn. The socket swivels, so you won’t have to twist your hose to attach the plug. It also has a rubber lip and large handles to prevent damage if it’s dropped.

A complete coupling consists of a plug and a socket (both sold separately). They’re compatible with MannTek, Avery Hardoll, Todo-matic, and other dry-disconnect couplings that meet NATO standard STANAG 3756.

Aluminum couplings are lighter in weight than stainless steel and have good corrosion resistance.

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F