Filter by

Shell Material

Tube Material

For Use With

System of Measurement

Flow Capacity

Heating/Cooling Capacity

Maximum Temperature

Maximum Pressure

Heat Exchanger Type

Overall Height

Overall Width

Overall Length

Surface Area

Minimum Temperature

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Plate Material

Heat Sink Material

High-Efficiency Heat Exchangers

Overall | Mounting Hole | Mounting Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Heating/Cooling Cap., BTU/hr | Surface Area, ft² | Temp. Range, ° F | Pipe Size | Thread Type | Gender | Flow Cap., gpm | Max. Pressure, psi | Ht. | Wd. | Dp. | No. of | Dia. | No. of | Thread Size | Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat Exchangers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Brazed 316 Stainless Steel Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16,000 | 3.1 | -320 to 390 | 1 | NPT | Male | 4 | 360 | 13 3/16" | 4 7/8" | 2 3/16" | — | — | 4 | M10 | 13/16" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37,000 | 6.8 | -320 to 390 | 1 | NPT | Male | 9 | 360 | 13 3/16" | 4 7/8" | 3 1/16" | — | — | 4 | M10 | 13/16" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 56,000 | 10.6 | -320 to 390 | 1 | NPT | Male | 13 | 360 | 13 3/16" | 4 7/8" | 4" | — | — | 4 | M10 | 13/16" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 74,000 | 14.3 | -320 to 390 | 1 | NPT | Male | 18 | 360 | 13 3/16" | 4 7/8" | 4 7/8" | — | — | 4 | M10 | 13/16" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120,000 | 40.7 | -320 to 390 | 2 | NPT | Male | 30 | 390 | 20 15/16" | 10 11/16" | 4 1/16" | — | — | 4 | M12 | 1 3/16" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UL Listed Heat Exchangers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper-Brazed 316 Stainless Steel Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 69,000 | 2.2 | -320 to 350 | 3/4 | NPT | Male | 7 | 450 | 9 1/8" | 3 1/2" | 2 5/8" | — | — | 2 | M8 | 20 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80,000 | 3 | -320 to 350 | 1 | NPT | Male | 8 | 450 | 13 3/16" | 5" | 1 1/4" | — | — | 4 | M10 | 20 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 185,000 | 6.8 | -320 to 350 | 1 | NPT | Male | 19 | 450 | 13 3/16" | 5" | 2" | — | — | 4 | M8 | 20 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 390,000 | 14.3 | -320 to 350 | 1 | NPT | Male | 40 | 450 | 13 3/16" | 5" | 4" | — | — | 4 | M10 | 20 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 570,000 | 21.9 | -320 to 350 | 1 1/4 | NPT | Male | 58 | 450 | 13 3/16" | 5" | 5 3/4" | — | — | 4 | M8 | 20 mm | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 998,000 | 41 | -320 to 390 | 2 | NPT | Male | 120 | 450 | 20 15/16" | 10 11/16" | 3 1/8" | — | — | 4 | M12 | 30 mm | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,710,000 | 68.3 | -320 to 390 | 2 | NPT | Male | 120 | 450 | 20 15/16" | 10 11/16" | 4 15/16" | — | — | 4 | M12 | 30 mm | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ASME BPVC.VIII.1 Certified Heat Exchangers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper-Brazed 316 Stainless Steel Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5,000 | 4.8 | -310 to 450 | 3/4 | NPT | Male | 27 | 435 | 8 7/16" | 3 3/16" | 4 7/16" | 2 | 9/32" | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 7.9 | -310 to 450 | 1 | NPT | Male | 29 | 435 | 12 3/16" | 4 3/8" | 4 1/4" | 2 | 13/32" | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17,000 | 10.7 | -310 to 450 | 1 | NPT | Male | 37 | 435 | 12 3/16" | 4 3/8" | 5 1/4" | 2 | 13/32" | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50,000 | 15.6 | -310 to 450 | 1 | NPT | Male | 22 | 435 | 20 11/16" | 4 3/8" | 4 1/4" | 2 | 13/32" | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75,000 | 26.8 | -310 to 450 | 1 | NPT | Male | 34 | 435 | 20 11/16" | 4 3/8" | 6 3/16" | 2 | 13/32" | — | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125,000 | 29.7 | -310 to 450 | 2 | NPT | Male | 57 | 435 | 24 5/16" | 7 1/2" | 5 3/4" | 4 | 1/2" | — | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 380,000 | 82.8 | -310 to 450 | 2 | NPT | Male | 141 | 435 | 24 5/16" | 7 1/2" | 11 1/2" | 4 | 1/2" | — | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat Exchangers

NPT Female Threaded Shell-Side and Tube-Side Connections

Temp., ° F | Shell-Side | Tube Side | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Heating/Cooling Cap., BTU/hr | Surface Area, ft² | No. of Passes | Min. | Max. | Pipe Size | Flow Cap., gpm | Max. Pressure, psi | Pipe Size | Flow Cap., gpm | Max. Pressure, psi | Lg. | Head Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Shell and Baffled 316 Stainless Steel Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 130,000 | 2.4 | 4 | -20 | 450 | 1 | 32 | 225 | 3/4 | 12 | 150 | 10 3/8" | 4 3/16" | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 195,000 | 4.3 | 4 | -20 | 450 | 1 | 32 | 225 | 3/4 | 12 | 150 | 16 3/8" | 4 3/16" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 280,000 | 7.4 | 4 | -20 | 450 | 1 | 32 | 225 | 3/4 | 12 | 150 | 26 3/8" | 4 3/16" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350,000 | 9.1 | 4 | -20 | 450 | 1 1/2 | 76 | 225 | 1 | 30 | 150 | 17 13/16" | 6 1/2" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 560,000 | 15.7 | 4 | -20 | 450 | 1 1/2 | 76 | 225 | 1 | 30 | 150 | 27 13/16" | 6 1/2" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 890,000 | 23 | 4 | -20 | 450 | 2 | 126 | 225 | 1 1/2 | 57 | 150 | 28 1/8" | 7 1/2" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,115,000 | 34 | 4 | -20 | 450 | 2 | 126 | 225 | 1 1/2 | 57 | 150 | 40 1/8" | 7 1/2" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,585,000 | 41 | 4 | -20 | 450 | 3 | 220 | 225 | 2 | 104 | 150 | 28" | 9 3/4" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,000,000 | 62 | 4 | -20 | 450 | 3 | 220 | 225 | 2 | 105 | 150 | 40" | 9 3/4" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Heat Exchangers

NPT Female Threaded Shell-Side and Tube-Side Connections

Temp., ° F | Shell-Side | Tube Side | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Heating/Cooling Cap., BTU/hr | Surface Area, ft² | Max. Pressure for Steam, psi | Min. | Max. | Pipe Size | Flow Cap., gpm | Max. Pressure, psi | Pipe Size | Flow Cap., gpm | Max. Pressure, psi | Lg. | Head Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Shell and 316 Stainless Steel Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 59,000 | 0.4 | 125 | -320 | 800 | 1/4 | 4.8 | 1,000 | 3/8 | 10.9 | 1,500 | 9 3/4" | 1 1/8" | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65,500 | 0.61 | 125 | -320 | 800 | 1/4 | 4.4 | 1,000 | 3/8 | 9.3 | 1,500 | 13 3/4" | 1 1/8" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 76,500 | 0.58 | 125 | -320 | 800 | 1/4 | 4.8 | 1,000 | 3/8 | 10.1 | 1,500 | 9 3/4" | 1 1/8" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90,000 | 0.89 | 125 | -320 | 800 | 1/4 | 4.4 | 1,000 | 3/8 | 8.4 | 1,500 | 13 3/4" | 1 1/8" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 98,000 | 1.19 | 125 | -320 | 800 | 1/4 | 4.2 | 1,000 | 3/8 | 7.3 | 1,500 | 17 3/4" | 1 1/8" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

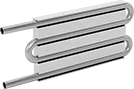

Cold Plates

|  |  |  |

4 Passes | 6 Passes | 316 Stainless Steel Fitting, 4 Passes | 316 Stainless Steel Fitting, 6 Passes |

Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Material | Tube OD | Pipe Size | Thread Type | Max. Pressure, psi | Max. Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Tubes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Passes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3 1/2" | 1/2" | Aluminum | 3/8" | — | — | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 3 1/2" | 1/2" | Aluminum | 3/8" | — | — | 1,000 | 450 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 Passes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 5 1/2" | 1/2" | Aluminum | 3/8" | — | — | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 5 1/2" | 1/2" | Aluminum | 3/8" | — | — | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Tubes and 316 Stainless Steel Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Passes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3 1/2" | 1/2" | Aluminum | 3/8" | 1/4 | NPT | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 3 1/2" | 1/2" | Aluminum | 3/8" | 1/4 | NPT | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 Passes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 5 1/2" | 1/2" | Aluminum | 3/8" | 1/4 | NPT | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 5 1/2" | 1/2" | Aluminum | 3/8" | 1/4 | NPT | 1,000 | 450 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

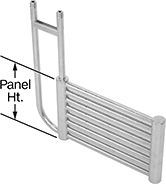

Open-Tank Heat Exchangers

Temp. | Inlet | Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Surface Area, ft² | Flow Cap., gpm | Max. Pressure, psi | Min. | Max. | Heat Exchanger Type | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Overall Ht. | Wd. | Panel Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.8 | 9 | 100 | Not Rated | Not Rated | Coil Panel | 3/4 | NPT | Male | 3/4 | NPT | Male | 24" | 24" | 12" | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.8 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 24" | 24" | 12" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.8 | 9 | 100 | Not Rated | Not Rated | Coil Panel | 3/4 | NPT | Male | 3/4 | NPT | Male | 24" | 30" | 12" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.6 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 30" | 24" | 18" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.8 | 9 | 100 | Not Rated | Not Rated | Coil Panel | 3/4 | NPT | Male | 3/4 | NPT | Male | 24" | 36" | 12" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.8 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 24" | 36" | 12" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.5 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 36" | 24" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.6 | 9 | 100 | Not Rated | Not Rated | Coil Panel | 3/4 | NPT | Male | 3/4 | NPT | Male | 36" | 30" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.6 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 36" | 30" | 24" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11.7 | 9 | 100 | Not Rated | Not Rated | Coil Panel | 3/4 | NPT | Male | 3/4 | NPT | Male | 36" | 36" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11.7 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 36" | 36" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15.9 | 9 | 100 | Not Rated | Not Rated | Coil Panel | 3/4 | NPT | Male | 3/4 | NPT | Male | 36" | 48" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15.9 | 24 | 100 | Not Rated | Not Rated | Coil Panel | 1 | NPT | Male | 3/4 | NPT | Male | 36" | 48" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20.1 | 41 | 100 | Not Rated | Not Rated | Coil Panel | 1 1/2 | NPT | Male | 3/4 | NPT | Male | 36" | 60" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24.3 | 41 | 100 | Not Rated | Not Rated | Coil Panel | 1 1/2 | NPT | Male | 3/4 | NPT | Male | 36" | 72" | 24" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat Exchangers for Sampling

NPT Female Threaded Shell-Side and Tube-Side Connections

| |

1.3 ft² Surface Area | 3.8 ft² Surface Area |

Shell-Side | Tube Side | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Heating/Cooling Cap. | Surface Area, ft² | Pipe Size | Flow Cap., gpm | Max. Pressure, psi | Max. Temp., ° F | Pipe Size | Flow Cap., gpm | Max. Pressure, psi | Max. Temp., ° F | Lg. | Head Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Shell and 316 Stainless Steel Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not Rated | 1.3 | 1/4 | 2 | 150 | 450 | 1/4 | 4 | 3,000 | 750 | 17 1/4" | 3 1/2" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not Rated | 3.8 | 3/8 | 2 | 150 | 450 | 1/4 | 4 | 4,900 | 750 | 32 5/8" | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Threaded Shell-Side and Male Threaded Tube-Side Connections

Shell-Side | Tube Side | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Surface Area, ft² | Pipe Size | Flow Cap. | Max. Pressure, psi | Max. Temp., ° F | Pipe Size | Flow Cap. | Max. Pressure, psi | Max. Temp., ° F | Lg. | Head Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Shell and 304 Stainless Steel Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.64 | 1/2 | Not Rated | 250 | 650 | 1/4 | Not Rated | 900 | 750 | 19" | 7" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

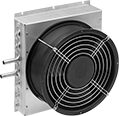

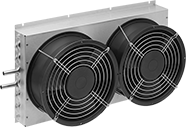

Heat Sinks for Water

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Gender | Ht. | Wd. | Dp. | Heat Sink Material | No. of Fans | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., ° F | Voltage (Electrical Phase) | Current, amp | Cord Lg., ft. | Mounting Slot Wd. | Tube OD | Choose a Fitting Connection | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Tube—For Corrosive Liquids and Deionized Water | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,300 | Male | 6 9/16" | 7" | 2 13/16" | Stainless Steel | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,500 | Male | 5 13/16" | 6 1/8" | 3 11/16" | Stainless Steel | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,200 | Male | 5 13/16" | 10 7/8" | 3 11/16" | Stainless Steel | 2 | 150 | 2 | 400 | 120V AC (Single) | 0.16 | 2 | 3/16" | 3/8" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,200 | Male | 9" | 9 3/16" | 4 13/16" | Stainless Steel | 1 | 150 | 2 | 400 | 120V AC (Single) | 0.25 | 2 | 3/16" | 3/8" | 37° Flared , Tube Stem | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,400 | Male | 12" | 11 3/16" | 6 1/16" | Stainless Steel | 1 | 150 | 4 | 400 | 120V AC (Single) | 0.29 | 2 | 3/16" | 1/2" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7,100 | Male | 9" | 17 3/16" | 4 1/2" | Stainless Steel | 2 | 150 | 2 | 400 | 120V AC (Single) | 0.25 | 2 | 3/16" | 3/8" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8,800 | Male | 12" | 21 3/16" | 6 1/16" | Stainless Steel | 2 | 150 | 4 | 400 | 120V AC (Single) | 0.29 | 2 | 3/16" | 1/2" | Tube Stem | 000000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Enclosure-Cooling Heat Exchangers

Overall | For Opening | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Airflow, ft³/min | Wattage, W | Current, amp | Ht. | Wd. | Dp. | Ht. | Wd. | Material | Thermostat Included | For Use Outdoors | Mounting Fasteners Included | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 4X, IP56 Enclosure Rating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase, 50 Hz/60 Hz—3 Straight Blade Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,400 | Not Rated | 80 | 0.7 | 12" | 12" | 8" | 11" | 11" | Stainless Steel | No | Yes | Yes | UL Listed C-UL Listed CE Marked | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,000 | Not Rated | 160 | 1.4 | 23" | 12" | 8" | 21 3/4" | 11" | Stainless Steel | No | Yes | Yes | UL Listed C-UL Listed CE Marked | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase, 60 Hz—Screw Terminal Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,400 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6,800 | 180 | 75 | 0.9 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,200 | 560 | 345 | 2.8 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

230V AC, Single Phase, 50 Hz/60 Hz—Screw Terminal Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,400 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6,800 | 180 | 75 | 0.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,200 | 560 | 245 | 1.4 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

460V AC, Single Phase, 50 Hz/60 Hz—Screw Terminal Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,400 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6,800 | 180 | 75 | 0.2 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,200 | 560 | 245 | 0.7 | 35" | 12" | 11" | 17" | 10" | Stainless Steel | Yes | Yes | Yes | UL Listed C-UL Listed | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Temperature Liquid Chillers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Voltage (Electrical Phase) | Current, amp | Compressor Power, hp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Temp. Control Range, ° F | Ht. | Wd. | Dp. | Tank Cap., gal. | Refrigerant No. | Features | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Closed-Loop Fluid Cooling Systems | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13,600 | 460V AC (Three Phase) | 22 | 2 | 10 gpm @ 28 psi | 150 | 0 to 40 | 54 3/8" | 31 5/8" | 31 5/8" | 12 | R-448A | Liquid-Level Sight Glass | Canada | 0000000 | 0000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Liquid Chillers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling Cap., BTU/hr | Current, amp | Compressor Power, hp | Max. Flow Rate @ Pressure | Max. Pressure, psi | Temp. Control Range, ° F | Ht. | Wd. | Dp. | Electrical Connection Type | Connection End Type | Tank Cap., gal. | Refrigerant No. | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

460V AC (Three Phase) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 6 | 1 | 4 gpm @ 50 psi | 50 | 50 to 80 | 33 3/8" | 24 3/8" | 34 3/8" | Plug In | Male Receptacle | 12 | R-513A | Bypass Valve, Electrical Cords with Shut-Off Switch, Liquid-Level Sight Glass | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||