Filter by

Thread Size

Movement

Thread Length

Body Style

Inside Width

Overall Height

Shank Length

Eye Diameter

Weight Capacity

Installation Torque

Threading

Safety Factor

Specifications Met

Height

Overall Length

Export Control Classification Number (ECCN)

REACH

DFARS Specialty Metals

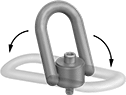

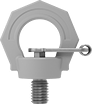

Hoist Rings—For Lifting

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Inside Wd. | Overall Ht. | Vert. Cap., lb. | Movement | Specs. Met | Certification | Mil. Spec. | 1-9 | 10-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged 17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/2" | 4 1/8" | 800 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T71 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 9/16" | 1 1/2" | 4 1/8" | 1,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T72 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 11/16" | 3" | 7 1/8" | 2,500 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T73 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1" | 3" | 7 3/8" | 2,500 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T81 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 1/4" | 3" | 7 5/8" | 4,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T82 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/8" | 3" | 7 1/2" | 5,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T75 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12 mm | 38 mm | 103 mm | 875 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T76 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 38 mm | 106 mm | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T77 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 18 mm | 76 mm | 179 mm | 2,300 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T78 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 24 mm | 76 mm | 185 mm | 4,175 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 3046T79 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machined 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 9/16" | 15/16" | 3 1/4" | 300 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T24 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 5/16" | 15/16" | 3" | 400 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T25 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 9/16" | 15/16" | 3 1/4" | 400 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T31 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 9/16" | 15/16" | 3 1/4" | 500 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T32 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3/4" | 1 7/8" | 5 3/4" | 1,250 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T34 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1" | 1 7/8" | 5 31/32" | 1,250 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T26 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 1/16" | 1 7/16" | 4 7/8" | 1,250 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T33 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 5/16" | 1 7/8" | 6 1/4" | 1,250 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T35 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 1/16" | 1 7/8" | 6" | 2,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T36 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 5/16" | 1 7/8" | 6 1/4" | 2,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T37 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/16" | 1 7/8" | 6" | 2,500 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T38 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 9/16" | 1 7/8" | 6 1/2" | 2,500 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T39 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/16" | 2 7/8" | 7 5/8" | 4,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T29 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 5/16" | 2 7/8" | 8 7/8" | 5,000 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T46 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 22 mm | 81 mm | 425 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T61 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 18 mm | 22 mm | 86 mm | 550 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T62 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 19 mm | 44 mm | 140 mm | 1,150 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T63 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 29 mm | 44 mm | 150 mm | 2,075 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T64 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 34 mm | 44 mm | 155 mm | 2,350 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T65 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 37 mm | 72 mm | 203 mm | 4,600 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 2949T66 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Eye Nuts—For Lifting

|  |  |

Style A | Style B | Style C |

Fully Threaded

|

Style A |

|

Style B |

|

Style C |

Style | Thread Size | Overall Lg. | Eye Dia. | Vert. Cap., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M6 × 1 mm | 36 mm | 20 mm | 150 | 3155T21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M8 × 1.25 mm | 36 mm | 20 mm | 300 | 3155T11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M10 × 1.5 mm | 45 mm | 25 mm | 500 | 3155T12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M12 × 1.75 mm | 53 mm | 30 mm | 725 | 3155T13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M16 × 2 mm | 62 mm | 35 mm | 1,525 | 3155T14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M24 × 3 mm | 90 mm | 50 mm | 3,950 | 3155T17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M36 × 4 mm | 128 mm | 70 mm | 10,125 | 3155T19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-16 | 2 1/4" | 7/8" | 1,800 | 3061T43 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/2"-13 | 3" | 1 1/8" | 3,600 | 3061T44 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8"-11 | 3 3/4" | 1 3/8" | 5,800 | 3061T45 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/4"-10 | 3 7/8" | 1 1/2" | 10,600 | 3061T46 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/4"-20 | 1 5/8" | 3/4" | 500 | 3061T14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/16"-18 | 1 5/8" | 3/4" | 825 | 3061T15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3/8"-16 | 2 1/2" | 1 1/4" | 1,225 | 3061T25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/2"-13 | 2 1/2" | 1 1/4" | 2,225 | 3061T18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8"-11 | 3 1/8" | 1 1/2" | 3,600 | 3061T21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3/4"-10 | 3 7/8" | 1 3/4" | 5,200 | 3061T23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M6 × 1 mm | 43 mm | 19 mm | 475 | 3061T26 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M8 × 1.25 mm | 43 mm | 19 mm | 775 | 3061T27 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M10 × 1.5 mm | 64 mm | 32 mm | 1,150 | 3061T28 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M12 × 1.75 mm | 64 mm | 32 mm | 2,150 | 3061T29 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M16 × 2 mm | 84 mm | 38 mm | 3,425 | 3061T31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M18 × 2.5 mm | 99 mm | 42 mm | 4,700 | 3061T32 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M6 × 1 mm | 36 mm | 20 mm | 150 | 3174T19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M8 × 1.25 mm | 36 mm | 20 mm | 300 | 3174T11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M10 × 1.5 mm | 45 mm | 25 mm | 500 | 3174T12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M12 × 1.75 mm | 53 mm | 30 mm | 750 | 3174T13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M16 × 2 mm | 62 mm | 35 mm | 1,525 | 3174T14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M24 × 3 mm | 90 mm | 50 mm | 3,950 | 3174T16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

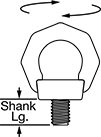

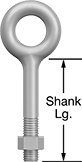

Eyebolts—For Lifting

304 Stainless Steel

|  |

Closed Eye With Shoulder | Closed Eye, Without Shoulder |

Thread | With Shoulder | Without Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Shank Lg. | Eye Dia. | Vert. Cap., lb. | Fastener Strength Grade/Class | Specs. Met | Threading | Overall Lg. | Each | Overall Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 1" | 3/4" | 450 | — | — | Fully Threaded | 2 3/8" | 33045T77 | 000000 | 2 3/8" | 33045T71 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/2" | 1 1/2" | 3/4" | 500 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 2 7/8" | 33045T33 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2" | 2" | 3/4" | 500 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 3 3/8" | 33045T32 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3" | 3" | 3/4" | 500 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 4 3/8" | 33045T31 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 4" | 4" | 3/4" | 500 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5 3/8" | 33045T29 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/8" | 1 1/8" | 7/8" | 775 | — | — | Fully Threaded | 2 3/4" | 33045T78 | 00000 | 2 3/4" | 33045T72 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/2" | 1 1/2" | 7/8" | 900 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 3 1/8" | 33045T28 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2" | 2" | 7/8" | 900 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 3 5/8" | 33045T27 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 3" | 3" | 7/8" | 900 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 4 5/8" | 33045T51 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 1 1/4" | 1" | 1,300 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 3 1/4" | 33045T81 | 00000 | 2 7/8" | 33045T79 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3" | 3" | 1" | 1,300 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5" | 33045T52 | 00000 | 4 5/8" | 33045T35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 4" | 4" | 1" | 1,300 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 6" | 33045T91 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 6" | 6" | 1" | 1,300 | ASTM Grade B8 | ASTM A193 | Fully Threaded | — | ——— | 0 | 7 3/4" | 33045T24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 1/2" | 1 1/2" | 1 3/16" | 2,150 | — | — | Fully Threaded | — | ——— | 0 | 3 5/8" | 33045T73 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 1/2" | 1 1/2" | 1 3/16" | 2,400 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 3 7/8" | 33045T82 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2 1/2" | 2 1/2" | 1 3/16" | 2,400 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5" | 33045T92 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3" | 3" | 1 3/16" | 2,400 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5 3/8" | 33045T53 | 00000 | 5" | 33045T34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 4" | 4" | 1 3/16" | 2,400 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 6 1/2" | 33045T93 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 6" | 6" | 1 3/16" | 2,400 | ASTM Grade B8 | ASTM A193 | Fully Threaded | — | ——— | 0 | 8" | 33045T25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 3/4" | 1 3/4" | 1 3/8" | 3,425 | — | — | Fully Threaded | — | ——— | 0 | 4 3/8" | 33045T74 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 3/4" | 1 3/4" | 1 3/8" | 4,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 4 5/8" | 33045T83 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 1/2" | 2 1/2" | 1 3/8" | 4,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5 1/2" | 33045T94 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 3" | 1 3/8" | 4,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5 7/8" | 33045T37 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4" | 4" | 1 3/8" | 4,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 7" | 33045T95 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 2" | 1 1/2" | 5,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 5 1/4" | 33045T84 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 2" | 1 1/2" | 5,125 | — | — | Fully Threaded | — | ——— | 0 | 4 7/8" | 33045T75 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3" | 3" | 1 1/2" | 5,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 6 1/4" | 33045T54 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4" | 4" | 1 1/2" | 5,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 7 1/4" | 33045T96 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 1/2" | 2 1/2" | 1 13/16" | 9,000 | — | — | Fully Threaded | 6 5/8" | 33045T85 | 000000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 1/2" | 2 1/2" | 1 13/16" | 9,350 | — | — | Fully Threaded | — | ——— | 0 | 6 1/8" | 33045T76 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 3" | 3" | 2 3/16" | 15,000 | ASTM Grade B8 | ASTM A193 | Fully Threaded | 8 1/4" | 33045T86 | 000000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 13 mm | 20 mm | 300 | — | DIN 580 | Fully Threaded | 49 mm | 3100T11 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 mm | 17 mm | 25 mm | 500 | — | DIN 580 | Fully Threaded | 62 mm | 3100T12 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 21 mm | 21 mm | 30 mm | 725 | — | DIN 580 | Fully Threaded | 73 mm | 3100T13 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 27 mm | 27 mm | 35 mm | 1,525 | — | DIN 580 | Fully Threaded | 89 mm | 3100T14 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 30 mm | 30 mm | 40 mm | 2,625 | — | DIN 580 | Fully Threaded | 101 mm | 3100T15 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 36 mm | 36 mm | 50 mm | 3,950 | — | DIN 580 | Fully Threaded | 126 mm | 3100T16 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 45 mm | 45 mm | 60 mm | 7,050 | — | DIN 580 | Fully Threaded | 154 mm | 3100T17 | 000000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel

|  |

Closed Eye With Shoulder | Closed Eye, Without Shoulder |

Thread | With Shoulder | Without Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Shank Lg. | Eye Dia. | Vert. Cap., lb. | Specs. Met | Threading | Overall Lg. | Each | Overall Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 1" | 3/4" | 500 | — | Fully Threaded | 2 3/8" | 8891T72 | 000000 | 2 1/4" | 8891T32 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3" | 3" | 3/4" | 500 | — | Fully Threaded | 4 3/8" | 8891T55 | 00000 | 4 1/4" | 8891T61 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/8" | 1 1/8" | 7/8" | 900 | — | Fully Threaded | — | ——— | 0 | 2 5/8" | 8891T35 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 3" | 3" | 7/8" | 900 | — | Fully Threaded | 4 5/8" | 8891T51 | 00000 | 4 1/2" | 8891T56 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 1 1/4" | 1" | 1,400 | — | Fully Threaded | 3 1/4" | 8891T88 | 00000 | 2 7/8" | 8891T48 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3" | 3" | 1" | 1,400 | — | Fully Threaded | 5" | 8891T52 | 00000 | 4 3/4" | 8891T57 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 1/2" | 1 1/2" | 1 3/16" | 2,600 | — | Fully Threaded | 4" | 8891T79 | 00000 | 3 1/2" | 8891T39 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3" | 3" | 1 3/16" | 2,600 | — | Fully Threaded | 5 3/8" | 8891T53 | 00000 | 5 1/8" | 8891T58 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 3/4" | 1 3/4" | 1 3/8" | 4,000 | — | Fully Threaded | 4 7/8" | 8891T82 | 00000 | 4 1/4" | 8891T42 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3" | 3" | 1 3/8" | 4,000 | — | Fully Threaded | 5 7/8" | 8891T54 | 00000 | 5 1/2" | 8891T59 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 2" | 1 1/2" | 6,000 | — | Fully Threaded | 5 1/4" | 8891T84 | 00000 | 4 3/4" | 8891T44 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 13 mm | 20 mm | 300 | DIN 580 | Fully Threaded | 49 mm | 3130T11 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 mm | 17 mm | 25 mm | 500 | DIN 580 | Fully Threaded | 62 mm | 3130T12 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 21 mm | 21 mm | 30 mm | 725 | DIN 580 | Fully Threaded | 73 mm | 3130T13 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 27 mm | 27 mm | 35 mm | 1,525 | DIN 580 | Fully Threaded | 89 mm | 3130T14 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 30 mm | 30 mm | 40 mm | 2,625 | DIN 580 | Fully Threaded | 101 mm | 3130T15 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 36 mm | 36 mm | 50 mm | 3,950 | DIN 580 | Fully Threaded | 126 mm | 3130T21 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 45 mm | 45 mm | 60 mm | 7,050 | DIN 580 | Fully Threaded | 154 mm | 3130T22 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M36 × 4 mm | 54 mm | 54 mm | 70 mm | 10,125 | DIN 580 | Fully Threaded | 182 mm | 3130T23 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Passivated 316 Stainless Steel

|

Closed Eye With Shoulder |

Thread | With Shoulder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Shank Lg. | Eye Dia. | Vert. Cap., lb. | Threading | Overall Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/8" | 1 1/8" | 15/16" | 900 | Fully Threaded | 3" | 8891T94 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Eyebolts with Nuts—For Lifting

304 Stainless Steel

|  |

Closed Eye With Shoulder | Closed Eye, Without Shoulder |

Thread | Nuts | With Shoulder | Without Shoulder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Shank Lg. | Eye Dia. | Vert. Cap., lb. | Threading | Number Included | Type | Overall Lg. | Each | Overall Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 4" | 1/2" | 450 | Partially Threaded | 1 | Hex | — | ——— | 0 | 5" | 3069T31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 4" | 3/4" | 450 | Partially Threaded | 1 | Hex | 5 3/8" | 3069T52 | 000000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/4" | 4" | 5/8" | 775 | Partially Threaded | 1 | Hex | — | ——— | 0 | 5 1/4" | 3069T32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/4" | 4" | 7/8" | 775 | Partially Threaded | 1 | Hex | 5 5/8" | 3069T53 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/2" | 4 1/2" | 3/4" | 1,150 | Partially Threaded | 1 | Hex | 6 1/4" | 3069T41 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 4 1/2" | 1" | 2,150 | Partially Threaded | 1 | Hex | 6 5/8" | 3069T54 | 00000 | 6 1/2" | 3069T33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2" | 6" | 1" | 2,150 | Partially Threaded | 1 | Hex | 8 3/8" | 3069T42 | 00000 | 8" | 3069T34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 1/2" | 4" | 1 3/8" | 3,425 | Partially Threaded | 1 | Hex | 7 1/8" | 3069T55 | 00000 | 6 1/2" | 3069T35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 1/2" | 6" | 1 3/8" | 3,425 | Partially Threaded | 1 | Hex | 9 1/8" | 3069T43 | 00000 | 8 1/2" | 3069T36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3" | 6" | 1 1/2" | 5,125 | Partially Threaded | 1 | Hex | 9 1/4" | 3069T44 | 000000 | 8 3/4" | 3069T37 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 3" | 6" | 1 3/4" | 7,125 | Partially Threaded | 1 | Hex | — | ——— | 0 | 9 1/2" | 3069T38 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3" | 6" | 2" | 9,350 | Partially Threaded | 1 | Hex | 10 3/4" | 3069T45 | 000000 | 10" | 3069T39 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel

|  |

Closed Eye With Shoulder | Closed Eye, Without Shoulder |

Thread | Nuts | With Shoulder | Without Shoulder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Shank Lg. | Eye Dia. | Vert. Cap., lb. | Threading | Number Included | Type | No. of Washers Included | Overall Lg. | Each | Overall Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 1 1/4" | 1/2" | 500 | Partially Threaded | 1 | Hex | — | 2 3/8" | 3032T64 | 000000 | 2 1/4" | 3032T51 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/2" | 2" | 1/2" | 500 | Partially Threaded | 1 | Hex | — | 3 1/8" | 3032T41 | 00000 | 3" | 3032T31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 2" | 4" | 1/2" | 500 | Partially Threaded | 1 | Hex | — | 5 1/8" | 3032T61 | 00000 | 5" | 3032T57 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/2" | 2 1/4" | 5/8" | 800 | Partially Threaded | 1 | Hex | — | 3 5/8" | 3032T42 | 00000 | 3 1/2" | 3032T32 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 2 1/2" | 4 1/4" | 5/8" | 800 | Partially Threaded | 1 | Hex | — | 5 5/8" | 3032T62 | 00000 | 5 1/2" | 3032T58 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 3/4" | 3/4" | 1,200 | Fully Threaded | 1 | Hex | — | 2 1/2" | 3032T66 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 3/4" | 3/4" | 1,200 | Fully Threaded | 1 | Hex | 1 | — | ——— | 0 | 2 1/4" | 3032T68 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1" | 1 1/2" | 3/4" | 1,200 | Partially Threaded | 1 | Hex | — | 3 1/4" | 3032T67 | 00000 | 3 1/8" | 3032T54 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/2" | 2 1/2" | 3/4" | 1,200 | Partially Threaded | 1 | Hex | — | 4 1/4" | 3032T43 | 00000 | 4" | 3032T33 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 2" | 4 1/4" | 3/4" | 1,200 | Partially Threaded | 1 | Hex | — | 6 1/8" | 3032T63 | 00000 | 6" | 3032T59 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 1/2" | 3 1/4" | 1" | 2,200 | Partially Threaded | 1 | Hex | — | 5 1/2" | 3032T44 | 00000 | 5 1/4" | 3032T34 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3" | 6" | 1" | 2,200 | Partially Threaded | 1 | Hex | — | 8 1/4" | 3032T45 | 00000 | 8" | 3032T35 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 4 1/2" | 1 1/4" | 3,500 | Partially Threaded | 1 | Hex | — | 7 1/4" | 3032T46 | 00000 | 6 3/4" | 3032T36 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 7/8" | 1" | 1 1/2" | 5,125 | Partially Threaded | 1 | Hex | 1 | 4" | 3032T108 | 00000 | 4" | 3032T118 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 3/4" | 2" | 1 1/2" | 5,125 | Partially Threaded | 1 | Hex | 1 | 5 1/8" | 3032T109 | 00000 | 4 7/8" | 3032T119 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/2" | 1 1/2" | 5,125 | Partially Threaded | 1 | Hex | 1 | 7 1/2" | 3032T47 | 00000 | 7 1/2" | 3032T37 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3" | 6" | 1 1/2" | 5,125 | Partially Threaded | 1 | Hex | 1 | 9 1/8" | 3032T124 | 000000 | 8 7/8" | 3032T125 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 2 1/2" | 5" | 1 3/4" | 7,125 | Partially Threaded | 1 | Hex | 1 | 8 5/8" | 3032T48 | 000000 | 8 1/2" | 3032T38 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 1 3/8" | 1 7/16" | 2" | 9,350 | Partially Threaded | 1 | Hex | 1 | 5 3/8" | 3032T112 | 000000 | 5 3/4" | 3032T122 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 1/4" | 2 1/2" | 2" | 9,350 | Partially Threaded | 1 | Hex | 1 | 6 3/8" | 3032T113 | 000000 | 6 7/8" | 3032T123 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3" | 6" | 2" | 9,350 | Partially Threaded | 1 | Hex | 1 | 9 7/8" | 3032T49 | 000000 | 10 3/8" | 3032T39 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 39 mm | 51 mm | 12 mm | 500 | Partially Threaded | 1 | Hex | 1 | 75 mm | 3032T11 | 0000 | 76 mm | 3032T77 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 39 mm | 58 mm | 16 mm | 800 | Partially Threaded | 1 | Hex | 1 | 90 mm | 3032T14 | 0000 | 87 mm | 3032T81 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 20 mm | 20 mm | 19 mm | 1,200 | Fully Threaded | 1 | Hex | 1 | 57 mm | 3032T16 | 00000 | 58 mm | 3032T83 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 39 mm | 64 mm | 19 mm | 1,200 | Partially Threaded | 1 | Hex | 1 | 101 mm | 3032T18 | 00000 | 103 mm | 3032T85 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 26 mm | 39 mm | 25 mm | 2,150 | Partially Threaded | 1 | Hex | 1 | 87 mm | 3032T21 | 00000 | 91 mm | 3032T87 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 39 mm | 83 mm | 25 mm | 2,150 | Partially Threaded | 1 | Hex | 1 | 131 mm | 3032T22 | 00000 | 136 mm | 3032T88 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 45 mm | 51 mm | 31 mm | 3,425 | Partially Threaded | 1 | Hex | 1 | 113 mm | 3032T25 | 00000 | 117 mm | 3032T92 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 2.5 mm | 26 mm | 26 mm | 38 mm | 5,125 | Fully Threaded | 1 | Hex | 1 | 102 mm | 3032T28 | 00000 | 102 mm | 3032T95 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 36 mm | 36 mm | 50 mm | 9,350 | Fully Threaded | 1 | Hex | 1 | 133 mm | 3032T74 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

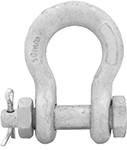

Anchor Shackles for Lifting

Thk. | Opening Wd. | Pin Dia. | Inside Lg. | Inside Wd. | Wt. Cap., lb. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 13/32" | 1/4" | 27/32" | 19/32" | 650 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T21 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 15/32" | 5/16" | 1 1/8" | 3/4" | 1,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 17/32" | 3/8" | 1 7/32" | 13/16" | 1,300 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 21/32" | 7/16" | 1 7/16" | 31/32" | 1,500 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 23/32" | 1/2" | 1 25/32" | 1 1/16" | 2,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 13/16" | 5/8" | 1 27/32" | 1 7/32" | 3,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/32" | 3/4" | 2 7/16" | 1 1/2" | 4,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 1/4" | 7/8" | 2 27/32" | 1 29/32" | 6,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 15/32" | 1" | 3 5/16" | 2 7/32" | 8,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 11/16" | 1 1/8" | 3 13/16" | 2 5/16" | 10,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/32" | 1 3/8" | 4 11/16" | 3 5/16" | 14,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Safety Cotter Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/2" | 5/16" | 1 1/8" | 3/4" | 1,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 17/32" | 3/8" | 1 7/32" | 13/16" | 1,300 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 11/16" | 7/16" | 1 7/16" | 31/32" | 1,500 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 25/32" | 1 1/16" | 2,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 27/32" | 5/8" | 1 27/32" | 1 7/32" | 3,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/32" | 3/4" | 2 7/16" | 1 1/2" | 4,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T26 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 1/4" | 7/8" | 2 27/32" | 1 3/4" | 6,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T27 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/2" | 1" | 3 5/16" | 2" | 8,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T28 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 23/32" | 1 1/8" | 3 13/16" | 2 5/16" | 10,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T29 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/32" | 1 3/8" | 4 11/16" | 3 5/16" | 14,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T31 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

D-Type Shackles for Lifting

Thk. | Opening Wd. | Pin Dia. | Inside Lg. | Inside Wd. | Wt. Cap., lb. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 15/32" | 5/16" | 7/8" | 15/32" | 1,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 17/32" | 13/32" | 1 1/32" | 17/32" | 1,300 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T112 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 21/32" | 15/32" | 1 1/4" | 21/32" | 1,500 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T113 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 7/16" | 3/4" | 2,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T119 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 13/16" | 21/32" | 1 19/32" | 13/16" | 3,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T114 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/16" | 3/4" | 1 31/32" | 1 1/16" | 4,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T115 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 7/32" | 29/32" | 2 13/32" | 1 7/32" | 6,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T116 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 15/32" | 1" | 2 29/32" | 1 15/32" | 8,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T117 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 11/16" | 1 5/32" | 3 7/32" | 1 11/16" | 10,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T118 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Safety Cotter Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 21/32" | 15/32" | 1 1/4" | 21/32" | 1,500 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T123 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 13/16" | 21/32" | 1 19/32" | 13/16" | 3,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T124 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/16" | 3/4" | 1 31/32" | 1 1/16" | 4,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T125 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 7/32" | 29/32" | 2 13/32" | 1 7/32" | 6,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T126 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 15/32" | 1" | 2 29/32" | 1 15/32" | 8,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T127 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 11/16" | 1 5/32" | 3 7/32" | 1 11/16" | 10,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T128 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||