Compare over 25 types of stainless steel to find the right material for you—all with material certificates for traceability.

Multipurpose 304 Stainless Steel

From cookware to chemical-processing equipment, 304 stainless steel is a good all-around choice for a wide range of applications. It maintains its corrosion resistance in temperatures up to 1500° F.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 30,000 psi

- Hardness: Not Rated

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met: ASTM A554

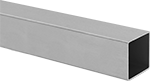

Outside | Inside | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Fabrication | Straightness Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

0.065" Wall Thick. (-0.007" to 0.007" Tolerance) | ||||||||||||

| 1/2" | -0.015" to 0.015" | 1/2" | -0.015" to 0.015" | 0.37" | 0.37" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3/4" | -0.015" to 0.015" | 3/4" | -0.015" to 0.015" | 0.62" | 0.62" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3/4" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 0.62" | 1.37" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1" | -0.015" to 0.015" | 1" | -0.015" to 0.015" | 0.87" | 0.87" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 0.87" | 1.37" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/4" | -0.015" to 0.015" | 1 1/4" | -0.015" to 0.015" | 1.12" | 1.12" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.37" | 1.37" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.37" | 1.87" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.87" | 1.87" | Welded | 1/8" per 3 ft. | 00000000 | ||||

0.083" Wall Thick. (-0.008" to 0.008" Tolerance) | ||||||||||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.334" | 1.334" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.834" | 1.834" | Welded | 1/8" per 3 ft. | 00000000 | ||||

0.12" Wall Thick. (-0.018" to 0.018" Tolerance) | ||||||||||||

| 2" | -0.030" to 0.030" | 6" | -0.030" to 0.030" | 1.76" | 5.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

0.12" Wall Thick. (-0.012" to 0.012" Tolerance) | ||||||||||||

| 1" | -0.015" to 0.015" | 1" | -0.015" to 0.015" | 0.76" | 0.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 0.76" | 1.26" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 0.76" | 1.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 0.76" | 2.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/4" | -0.015" to 0.015" | 1 1/4" | -0.015" to 0.015" | 1.01" | 1.01" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.26" | 1.26" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/2" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 1.26" | 2.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.76" | 1.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 1.76" | 2.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 1.76" | 3.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2 1/2" | -0.020" to 0.020" | 2 1/2" | -0.020" to 0.020" | 2.26" | 2.26" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2.76" | 2.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 4" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 3.76" | 3.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

0.18" Wall Thick. (-0.018" to 0.018" Tolerance) | ||||||||||||

| 1 1/2" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 1.14" | 2.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 1.64" | 2.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 1.64" | 3.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.060" to 0.060" | 6" | -0.060" to 0.060" | 1.64" | 5.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 2.64" | 3.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3" | -0.060" to 0.060" | 6" | -0.060" to 0.060" | 2.64" | 5.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 4" | -0.060" to 0.060" | 6" | -0.060" to 0.060" | 3.64" | 5.64" | Welded | 1/8" per 3 ft. | 00000000 | ||||

0.187" Wall Thick. (-0.019" to 0.019" Tolerance) | ||||||||||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.126" | 1.126" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.626" | 1.626" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2 1/2" | -0.020" to 0.020" | 2 1/2" | -0.020" to 0.020" | 2.126" | 2.126" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 4" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 3.626" | 3.626" | Welded | 1/8" per 3 ft. | 00000000 | ||||

1/4" Wall Thick. (-0.025" to 0.025" Tolerance) | ||||||||||||

| 2" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 1 1/2" | 2 1/2" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 1 1/2" | 3 1/2" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2 1/2" | 2 1/2" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 3" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 2 1/2" | 3 1/2" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 4" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 3 1/2" | 3 1/2" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 4" | -0.060" to 0.060" | 8" | -0.060" to 0.060" | 3 1/2" | 7 1/2" | Welded | 1/8" per 3 ft. | 00000000 | ||||

Polished Multipurpose 304 Stainless Steel

Polished to either a brushed or mirror-like finish, this material is widely used to fabricate decorative enclosures and industrial workstations. The sheets, strips, bars, and adhesive-back foil are covered with a protective peel-off film. 304 stainless steel is a good all-around choice for a wide range of applications. It maintains its corrosion resistance in temperatures up to 1500° F.

Brushed #4 is often called a satin finish; it’s similar to a #3 finish, except the grain lines are finer. Rectangular and round tubes are polished on the outside.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 30,000 psi

- Hardness: Not Rated

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met: ASTM A554

Outside | Inside | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Fabrication | Straightness Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

Brushed #4 | ||||||||||||

0.065" Wall Thick. (-0.007" to 0.007" Tolerance) | ||||||||||||

| 1" | -0.015" to 0.015" | 1" | -0.015" to 0.015" | 0.87" | 0.87" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.37" | 1.37" | Welded | 1/8" per 3 ft. | 00000000 | ||||

0.12" Wall Thick. (-0.012" to 0.012" Tolerance) | ||||||||||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.26" | 1.26" | Welded | 1/8" per 3 ft. | 00000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.76" | 1.76" | Welded | 1/8" per 3 ft. | 00000000 | ||||

Corrosion-Resistant 316 Stainless Steel

The addition of molybdenum gives 316 stainless steel excellent corrosion resistance. Use it in a variety of marine and chemical-processing applications. It maintains its corrosion resistance up to the maximum temperature.

316/316L stainless steel contains less carbon than standard 316 for better weldability.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: Not Rated

- Hardness: Rockwell B90 (Medium)

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met: ASTM A554

Outside | Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Fabrication | Max. Temp., °F | Straightness Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

316/316L Stainless Steel | |||||||||||||

0.062" Wall Thick. (-0.006" to 0.006" Tolerance) | |||||||||||||

| 3/4" | -0.015" to 0.015" | 3/4" | -0.015" to 0.015" | 0.626" | 0.626" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.376" | 1.376" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

0.065" Wall Thick. (-0.007" to 0.007" Tolerance) | |||||||||||||

| 1" | -0.015" to 0.015" | 1" | -0.015" to 0.015" | 0.87" | 0.87" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

0.12" Wall Thick. (-0.012" to 0.012" Tolerance) | |||||||||||||

| 1" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 0.76" | 1.26" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 1" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 0.76" | 1.76" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 1" | -0.015" to 0.015" | 1" | -0.015" to 0.015" | 0.76" | 0.76" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 1 1/2" | -0.020" to 0.020" | 1 1/2" | -0.020" to 0.020" | 1.26" | 1.26" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1.76" | 1.76" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2.76" | 2.76" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

0.18" Wall Thick. (-0.018" to 0.018" Tolerance) | |||||||||||||

| 2" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 1.64" | 3.64" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2.64" | 2.64" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

1/4" Wall Thick. (-0.025" to 0.025" Tolerance) | |||||||||||||

| 2" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 1 1/2" | 3 1/2" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 2" | -0.020" to 0.020" | 2" | -0.020" to 0.020" | 1 1/2" | 1 1/2" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2 1/2" | 2 1/2" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

| 4" | -0.030" to 0.030" | 4" | -0.030" to 0.030" | 3 1/2" | 3 1/2" | Welded | 1500° | 0.075" per 3 ft. | 0000000 | ||||

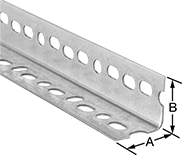

Aluminum Bolt-Together Framing and Fittings

Half the weight of steel, this aluminum framing resists corrosion in wet environments. Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

Slide locking pins in and out of the bolt holes on telescoping rails to quickly assemble, disassemble, and adjust them.

| For Rail Ht. | Material | Each | |

| 1 1/2", 1 3/4", 2" | 18-8 Stainless Steel | 0000000 | 00000 |

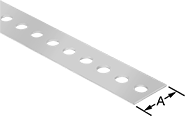

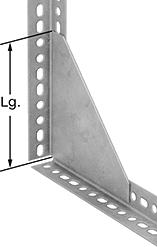

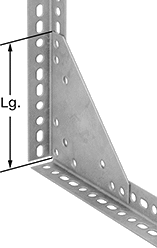

Flat and Angled Bolt-Together Framing and Fittings

Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

304 stainless steel rails are more corrosion resistant than galvanized steel. They also have good chemical resistance.

Surface brackets connect rails. These brackets do not have mounting holes already drilled, so you can drill holes where you need them or weld the brackets in place.

304 stainless steel brackets are more corrosion resistant than galvanized steel brackets. They also have good chemical resistance.

| Lg. | Thick. | Material | Mounting Fasteners Included | Each | |

| 6" | 0.08" | 304 Stainless Steel | No | 00000000 | 00000 |

Surface brackets connect rails.

304 stainless steel brackets are more corrosion resistant than galvanized steel brackets. They also have good chemical resistance.

| Lg. | Thick. | Material | Mounting Hole Shape | For Screw Size | Mounting Fasteners Included | Each | |

| 6" | 0.08" | 304 Stainless Steel | Round | 5/16" | No | 00000000 | 00000 |

Bracket fastener sets are required to connect brackets to rails.

| Lg. | Material | Thread Size | Includes | Pkg. Qty. | Pkg. | |

| 3/4" | 18-8 Stainless Steel | 5/16"-18 | 10 Bolts, 10 Metal Washers, 10 Nuts | 10 | 0000000 | 00000 |

Telescoping Weld-Together Rails

Create posts of varying lengths. To telescope rails, slide one length of rail into the next larger size rail (for example, a 1 3/4" height rail fits into a 2" height rail and a 3/4" dia. rail fits into a 1" dia. rail). Weld the rails together at the desired length to create strong structures. These rails are not compatible with weld-together framing and fittings.

304 stainless steel rails are more corrosion resistant than galvanized carbon steel. They also have good chemical resistance.

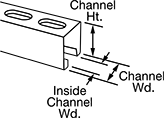

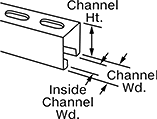

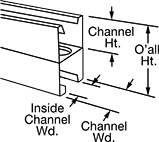

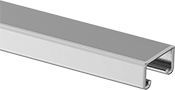

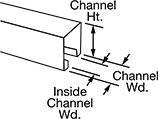

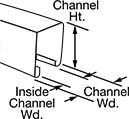

Strut Channel

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

316 stainless steel channel has excellent resistance to chemicals and salt water.

6'8" length channel is for use with beams spaced 6 ft. apart. The length allows 4" on each end to attach the channel to the beam.

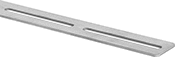

Low-Profile Strut Channel

Half the height and the same width as regular strut channel, this low-profile strut channel fits into tight spots and is compatible with many of the same brackets.

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

316 stainless steel channel has excellent resistance to chemicals and salt water.

6'8" length channel is for use with beams spaced 6 ft. apart. The length allows 4" on each end to attach the channel to the beam.

Extra Low-Profile Strut Channel

Run cable and tubing in the tightest spaces with channel that is one-quarter the height and one-half the width of regular strut channel.

304 stainless steel channel has better corrosion resistance than zinc-plated steel. It also has good chemical resistance.

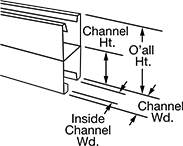

High-Profile Strut Channel

Up to two times the height of regular strut channel, this high-profile channel is stronger than regular strut channel.

316 stainless steel channel has excellent resistance to chemicals and salt water.

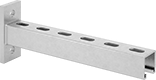

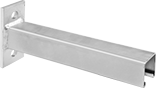

Strut Channel with Mounting Plate

Use the built-in mounting plate to secure strut channel to walls, posts, and beams.

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

316 stainless steel channel has excellent resistance to chemicals and salt water.

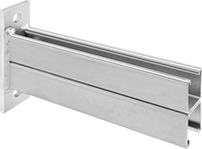

Back-to-Back Stacked Strut Channel with Mounting Plate

Use the built-in mounting plate to secure strut channel to walls, posts, and beams.

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

316 stainless steel channel has excellent resistance to chemicals and salt water.

Curved Strut Channel

Create continuous runs of channel without corners.

304 stainless steel channel resists corrosion better than zinc-plated steel channel. It also has good chemical resistance.

Channel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Material | Angle | Ht. | Wd. | Lg., ft. | Thick. | Inside Channel Wd. | Radius, ft. | Each | |

| 304 Stainless Steel | 90° | 1 5/8" | 1 5/8" | 4 1/2 | 0.11" | 7/8" | 3 | 0000000 | 0000000 |

Back-to-Back Stacked Strut Channel

This welded, one-piece strut channel combines two strut channels back-to-back.

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

Food Industry Strut Rails

A flat or half-round shape keeps water from pooling on these strut rails. Unlike a traditional C-shape strut, these rails prevent the buildup of bacteria and debris, making them ideal for use in sanitary or food production environments. Made of stainless steel, they’re more corrosion resistant than zinc-plated and galvanized steel rails. They also have good chemical resistance.

Flat rails can be mounted on walls horizontally or vertically.

Half-round rails are dome-shaped, so they protect threads.