How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

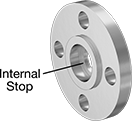

Low-Pressure Stainless Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through. Forged flanges have better strength than cast flanges. 304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met

4-8 pipe size: ASTM 182

All other pipe sizes: ASME B16.5, ASTM A182 - Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

Bolt Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | |

304/304L Stainless Steel | ||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 230 psi @ 72° F | 000000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 230 psi @ 72° F | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 230 psi @ 72° F | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 230 psi @ 72° F | 000000000 | 00000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 000000000 | 00000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 230 psi @ 72° F | 000000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 000000000 | 000000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 230 psi @ 72° F | 000000000 | 000000 |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 230 psi @ 72° F | 000000000 | 000000 |

| 8 | 13 1/2" | 3/4" | 7/8" | 8 | 11 3/4" | 230 psi @ 72° F | 000000000 | 000000 |

316/316L Stainless Steel | ||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 230 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 230 psi @ 72° F | 000000000 | 00000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 230 psi @ 72° F | 000000000 | 00000 |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 230 psi @ 72° F | 000000000 | 00000 |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 230 psi @ 72° F | 000000000 | 000000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 230 psi @ 72° F | 000000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 230 psi @ 72° F | 000000000 | 000000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 230 psi @ 72° F | 000000000 | 000000 |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 230 psi @ 72° F | 000000000 | 000000 |

| 8 | 13 1/2" | 3/4" | 7/8" | 8 | 11 3/4" | 230 psi @ 72° F | 000000000 | 000000 |

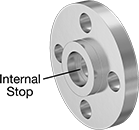

High-Pressure Stainless Steel Unthreaded Pipe Flanges

Use these heavy duty forged flanges for high-pressure applications. Bolt two flat-surface flanges or two raised-surface flanges of same size together with a gasket (sold separately) to create an access point in a pipe line.

304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

- For Use With:

4 and 6 Pipe Sizes: Air, Hydraulic Fluid, Natural Gas, Oil, Water

All other sizes: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water - Pressure Class: See table

- Specifications Met: See table

- Certification:: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Specifications Met | Each | |

304/304L Stainless Steel | |||||||||||

Pressure Class 300 | |||||||||||

| 1/2 | 08 | 600 psi @ 72° F | 300 psi @ 360° F | 3 3/4" | 1/2" | 0.625" | 4 | 2 5/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

| 1 | 16 | 600 psi @ 72° F | 300 psi @ 360° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

| 1 1/4 | 20 | 600 psi @ 72° F | 300 psi @ 360° F | 5 1/4" | 5/8" | 0.75" | 4 | 3 7/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 1 1/2 | 24 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/8" | 3/4" | 0.875" | 4 | 4 1/2" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

| 2 | 32 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/2" | 5/8" | 0.75" | 8 | 5" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 2 1/2 | 40 | 600 psi @ 72° F | 300 psi @ 360° F | 7 1/2" | 3/4" | 0.875" | 8 | 5 7/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 3 | 48 | 600 psi @ 72° F | 300 psi @ 360° F | 8 1/4" | 3/4" | 0.875" | 8 | 6 5/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 4 | 64 | 600 psi @ 72° F | 300 psi @ 360° F | 10" | 3/4" | 0.875" | 8 | 7 7/8" | ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 6 | 96 | 600 psi @ 72° F | 300 psi @ 360° F | 12 1/2" | 3/4" | 0.875" | 12 | 10 5/8" | ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

Pressure Class 600 | |||||||||||

| 1 | 16 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | ASME B16.5, ASTM A182 | 0000000 | 00000 |

| 1 1/2 | 24 | 1,200 psi @ 72° F | 840 psi @ 400° F | 6 1/8" | 3/4" | 0.875" | 4 | 4 1/2" | ASME B16.5, ASTM A182 | 0000000 | 000000 |

| 2 | 32 | 1,200 psi @ 72° F | 840 psi @ 400° F | 6 1/2" | 5/8" | 0.75" | 8 | 5" | ASME B16.5, ASTM A182 | 0000000 | 000000 |

| 3 | 48 | 1,200 psi @ 72° F | 840 psi @ 400° F | 8 1/4" | 3/4" | 0.88" | 8 | 6 5/8" | ASME B16.5, ASTM A182 | 0000000 | 000000 |

316/316L Stainless Steel | |||||||||||

Pressure Class 300 | |||||||||||

| 1/2 | 08 | 600 psi @ 72° F | 300 psi @ 360° F | 3 3/4" | 1/2" | 0.625" | 4 | 2 5/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

| 1 | 16 | 600 psi @ 72° F | 300 psi @ 360° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

| 1 1/4 | 20 | 600 psi @ 72° F | 300 psi @ 360° F | 5 1/4" | 5/8" | 0.75" | 4 | 3 7/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 1 1/2 | 24 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/8" | 3/4" | 0.875" | 4 | 4 1/2" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 2 | 32 | 600 psi @ 72° F | 300 psi @ 360° F | 6 1/2" | 5/8" | 0.75" | 8 | 5" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 3 | 48 | 600 psi @ 72° F | 300 psi @ 360° F | 8 1/4" | 3/4" | 0.875" | 8 | 6 5/8" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

| 4 | 64 | 600 psi @ 72° F | 300 psi @ 360° F | 10" | 3/4" | 0.875" | 8 | 7 7/8" | ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

Pressure Class 600 | |||||||||||

| 1/2 | 08 | 1,200 psi @ 72° F | 840 psi @ 400° F | 3 3/4" | 1/2" | 0.62" | 4 | 2 5/8" | ASME B16.5, ASTM A182 | 0000000 | 00000 |

| 3/4 | 12 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | ASME B16.5, ASTM A182 | 0000000 | 00000 |

| 1 | 16 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 7/8" | 5/8" | 0.75" | 4 | 3 1/2" | ASME B16.5, ASTM A182 | 0000000 | 000000 |

| 1 1/2 | 24 | 1,200 psi @ 72° F | 840 psi @ 400° F | 6 1/8" | 3/4" | 0.875" | 4 | 4 1/2" | ASME B16.5, ASTM A182 | 0000000 | 000000 |

| 2 | 32 | 1,200 psi @ 72° F | 840 psi @ 400° F | 6 1/2" | 5/8" | 0.75" | 8 | 5" | ASME B16.5, ASTM A182 | 0000000 | 000000 |

High-Pressure Stainless Steel Unthreaded SAE Pipe Flanges

Create an access point in a high-pressure hydraulic fluid line with these flanges. They are also known as Code 61 SAE hydraulic flanges. To connect, bolt a flange with an O-ring groove surface to a flange with a flat surface of the same size. Flanges are 316 stainless steel for excellent corrosion resistance.

Socket-connect flanges weld to pipe for a strong, permanent connection.

- For Use With: Hydraulic Fluid

- Specifications Met: SAE J518, ISO 6162

Flange | Bolt Hole | 316/316L Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | SAE Flange Size | Dash Size | Max. Pressure | Ht. | Wd. | Dp. | Mounting Hardware Included | For Bolt Dia. | Dia. | No. of | Ctr.-to-Ctr. | Each | |

| 3/4 | 3/4 | 12 | 5,000 psi @ 72° F | 2 5/8" | 1 3/4" | 15/16" | No | 3/8" | 0.406" | 4 | 7/8", 1 7/8" | 0000000 | 0000000 |

| 1 | 1 | 16 | 5,000 psi @ 72° F | 2 53/64" | 2" | 15/16" | No | 3/8" | 0.406" | 4 | 1.031", 2.062" | 00000000 | 000000 |

| 1 1/2 | 1 1/2 | 24 | 3,000 psi @ 72° F | 3 3/4" | 2 3/4" | 1 3/16" | No | 1/2" | 0.531" | 4 | 1.406", 2 3/4" | 00000000 | 000000 |

| 2 | 2 | 32 | 3,000 psi @ 72° F | 4" | 3 1/4" | 1 7/16" | No | 1/2" | 0.531" | 4 | 1.688", 3.062" | 00000000 | 000000 |

- For Use With: Hydraulic Fluid

- Specifications Met: SAE J518, ISO 6162

Flange | Bolt Hole | 316/316L Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | SAE Flange Size | Dash Size | Max. Pressure | Ht. | Wd. | Dp. | Mounting Hardware Included | For Bolt Dia. | Dia. | No. of | Ctr.-to-Ctr. | Each | |

| 3/4 | 3/4 | 12 | 5,000 psi @ 72° F | 2 5/8" | 1 3/4" | 15/16" | Yes | 3/8" | 0.406" | 4 | 7/8", 1 7/8" | 00000000 | 0000000 |

| 1 | 1 | 16 | 5,000 psi @ 72° F | 2 53/64" | 2" | 15/16" | Yes | 3/8" | 0.406" | 4 | 1.031", 2.062" | 00000000 | 000000 |

| 1 1/2 | 1 1/2 | 24 | 3,000 psi @ 72° F | 3 3/4" | 2 3/4" | 1 3/16" | Yes | 1/2" | 0.531" | 4 | 1.406", 2 3/4" | 00000000 | 000000 |

| 2 | 2 | 32 | 3,000 psi @ 72° F | 4" | 3 1/4" | 1 7/16" | Yes | 1/2" | 0.531" | 4 | 1.688", 3.062" | 00000000 | 000000 |

Flanged Ultra-High-Vacuum Fittings for Stainless Steel Tubing

- For Use With: Air

- Temperature Range:

Flanges: -300° to 800° F

Gaskets: Not Rated - Tubing: Use with 304/304L and 316/316L stainless steel

- Specifications Met:

Flanges: ASTM A240, ASTM E45, ASTM E12

Gaskets: ASTM B152-179, ASTM F68

Create access points in ultra-high-vacuum lines or chambers by bolting two same-size flanges together with a copper gasket (sold separately) between them. The flanges’ sharp edges dig into the copper gasket and form an extremely tight seal, which means they handle higher vacuum pressures than other high-vacuum fittings with rubber gaskets. Also known as CF, Conflat, and UHV fittings, use them in vacuum coating, heat treating, and drying applications, as well as for leak testing and analyzing gases. They’re stainless steel so they resist rusting.

Fittings with a rotating flange turn so you can easily match up the bolt holes with another flange that may be misaligned.

Socket-connect flanges are easier to weld than butt-weld flanges because they don’t need to align perfectly to tubing; insert the tubing into the socket end and weld together.

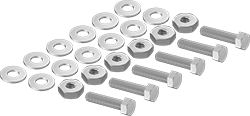

Bolt kits are required to make a complete connection.

Socket-Connect Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Socket Dp. | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||||

| 3/4" | 7/64" | 3/4" | 1 21/64" | 16 | CF | 11/16" | 3/16" | 6 | No | 1 | 5/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| 1 1/2" | 13/64" | 1 1/2" | 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | No | 1 | 1/2" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 00000 |

| 2 1/2" | 3/8" | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 1 | 11/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 00000 |

| 4" | 7/16" | 4" | 6" | 100 | CF | 5 1/8" | 21/64" | 16 | No | 2 | 25/32" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

Rotating | ||||||||||||||||

| 3/4" | 1/8" | 3/4" | 1 21/64" | 16 | CF | 11/16" | 3/16" | 6 | No | 1 | 5/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 00000 |

| 1 1/2" | 13/64" | 1 1/2" | 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | No | 1 | 1/2" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 00000 |

| 2 1/2" | 3/8" | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 1 | 11/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 00000 |

| 4" | 7/16" | 4" | 6" | 100 | CF | 5 1/8" | 21/64" | 16 | No | 2 | 25/32" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| For Flange OD | For High-Vacuum Flange Size | Bolt Dia. | Thread Size | No. of Bolts Included | No. of Nuts Included | No. of Washers Included | Bolt Material | Each | |

| 1 21/64" | 16 | 0.164" | 8-32 | 6 | 6 | 12 | 18-8 Stainless Steel | 0000000 | 00000 |

| 2 3/4" | 40 | 1/4" | 1/4"-28 | 6 | 6 | 12 | 18-8 Stainless Steel | 0000000 | 00000 |

| 4 1/2" | 63 | 5/16" | 5/16"-24 | 8 | 8 | 16 | 18-8 Stainless Steel | 0000000 | 00000 |

| 6" | 100 | 5/16" | 5/16"-24 | 16 | 16 | 32 | 18-8 Stainless Steel | 0000000 | 00000 |