Filter by

Mount Type

Thread Size

Diameter

Ball Material

Height

Housing Material

Weight Capacity

Shape

Maximum Temperature

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Housing Finish

Minimum Temperature

Performance

Fitting Connection

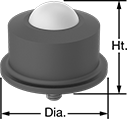

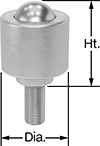

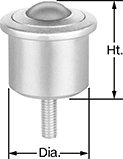

Stud-Mount Ball Transfers

|  |  |  |

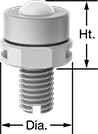

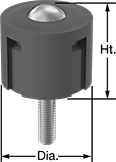

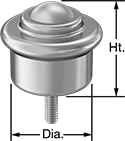

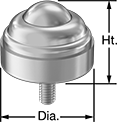

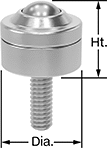

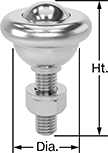

Style A | Style B | Style C | Style D |

|  |  |  |

Style E | Style H | Style L | Style M |

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8" | 125 | 13/16" | 15/16" | Ball Up, Ball Down, Angled | — | 1/4"-20 | 3/4" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1" | 200 | 1 1/4" | 1 13/32" | Ball Up, Ball Down, Angled | — | 5/16"-18 | 3/4" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 5/16"-18 | 11/16" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 3/4" | 55 | 31/32" | 1 9/32" | Ball Up, Ball Down, Angled | — | M8 | 1" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8" | 125 | 13/16" | 15/16" | Ball Up, Ball Down, Angled | — | 1/4"-20 | 3/4" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1" | 200 | 1 1/4" | 1 13/32" | Ball Up, Ball Down, Angled | — | 5/16"-18 | 3/4" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1" | 150 | 1 3/8" | 1 1/2" | Ball Up, Ball Down | — | 1/4"-20 | 23/32" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/8" | 200 | 53/64" | 15/16" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 100 | 1 17/32" | 1 27/32" | Ball Up | — | 1/4"-20 | 7/8" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 1/2" | 350 | 2 5/16" | 2 3/16" | Ball Up, Ball Down | — | 3/8"-16 | 1" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 125 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 1/4"-20 | 11/16" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 125 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 5/16"-18 | 11/16" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 125 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 3/8"-16 | 11/16" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/2" | 100 | 11/16" | 7/8" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 1" | 120 | 1 9/32" | 1 9/16" | Ball Up, Ball Down, Angled | — | M8 | 1" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 1" | 120 | 1 9/32" | 1 9/16" | Ball Up, Ball Down, Angled | — | M8 | 1 31/32" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | 3/16" | 20 | 1/4" | 5/16" | Ball Up | — | M2 | 3/32" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | 1/4" | 35 | 27/64" | 1/2" | Ball Up | — | M3 | 1/4" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | 5/16" | 55 | 1/2" | 19/32" | Ball Up, Ball Down, Angled | — | M4 | 5/16" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M | 1" | 110 | 1 3/8" | 2 1/16" | Ball Up, Ball Down, Angled | Gray | 5/16"-18 | 5/8" | 32 | 104 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/8" | 130 | 53/64" | 15/16" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | Not Rated | 400 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 65 | 1 17/32" | 1 27/32" | Ball Up | — | 1/4"-20 | 7/8" | Not Rated | 400 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 440 | 1 1/4" | 1 1/2" | Ball Up, Ball Down | — | 5/16"-18 | 3/4" | Not Rated | 400 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 1/4"-20 | 11/16" | Not Rated | 400 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 5/16"-18 | 11/16" | Not Rated | 400 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 3/8"-16 | 11/16" | Not Rated | 400 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/2" | 65 | 11/16" | 7/8" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | Not Rated | 400 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded-Hole-Mount Ball Knobs

|

Style 1 |

Thread | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Head Dia. | 1-9 | 10-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 3/4" | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 3/4" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 1 7/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 3/4" | 1 7/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3/4" | 1 7/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 1 3/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 3/4" | 1 7/8" | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clean Room Stud-Mount Ball Transfers

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Clean Room Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK/Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2 1/2 | 9/16" | 19/32" | Ball Up | Beige | M8 × 1.25 mm | 15/32" | 0 | 260 | Fed. Std. Class 1,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vespel® Polyimide Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vespel® Polyimide/Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 | 9/16" | 19/32" | Ball Up | Brown | M8 × 1.25 mm | 15/32" | 0 | 200 | Fed. Std. Class 1,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Washdown Stud-Mount Ball Transfers

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 525 | 1 3/4" | 2" | Ball Up, Ball Down, Angled | Black | M10 | 1 9/16" | -22 | 128 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

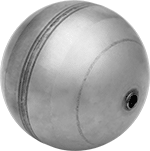

Through-Hole Floats

|

304 Stainless Steel Ball Floats—For Water

Dia. | Through-Hole Dia. | Max. Pressure, psi | Temp. Range, ° F | Ga. | For Container Type | Each | ||

|---|---|---|---|---|---|---|---|---|

| 2" | 1/4" | 300 | -30 to 225 | 24 | Open Tank | 0000000 | 000000 |

304 Stainless Steel Ball—For Water and Hydraulic Fluid

Dia. | Through-Hole Dia. | Max. Pressure, psi | Temp. Range, ° F | Ga. | For Container Type | Each | ||

|---|---|---|---|---|---|---|---|---|

| 3" | 1/4" | 250 | -30 to 225 | 24 | Open Tank | 0000000 | 000000 | |

| 4" | 1/4" | 500 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 4" | 3/8" | 500 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 5" | 3/8" | 400 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 6" | 1/4" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 6" | 3/8" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 6" | 1/2" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 7" | 3/8" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 8" | 3/8" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 8" | 1/2" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 |

316 Stainless Steel Ball Floats—For Water

Dia. | Through-Hole Dia. | Max. Pressure, psi | Temp. Range, ° F | Ga. | For Container Type | Each | ||

|---|---|---|---|---|---|---|---|---|

| 2" | 1/4" | 300 | -30 to 225 | 24 | Open Tank | 0000000 | 000000 |

316 Stainless Steel Ball Floats—For Hydraulic Fluid, For Water

Dia. | Through-Hole Dia. | Max. Pressure, psi | Temp. Range, ° F | Ga. | For Container Type | Each | ||

|---|---|---|---|---|---|---|---|---|

| 3" | 1/4" | 250 | -30 to 225 | 24 | Open Tank | 0000000 | 000000 | |

| 4" | 1/4" | 500 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 4" | 3/8" | 500 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 5" | 3/8" | 400 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 6" | 1/4" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 6" | 3/8" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 6" | 1/2" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 7" | 3/8" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 8" | 3/8" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 | |

| 8" | 1/2" | 150 | -30 to 225 | 20 | Open Tank | 0000000 | 000000 |

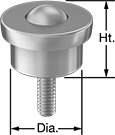

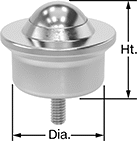

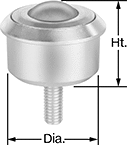

Heavy Duty Stud-Mount Ball Transfers

|  |  |

Style A | Style B | Style C |

Style | Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Thread Size | Stud Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Stainless Steel Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 3/16" | 700 | 1 7/16" | 1 3/4" | Ball Up, Ball Down, Angled | 3/8"-16 | 1" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 500 | 2 3/16" | 2 3/8" | Ball Up, Ball Down, Angled | M12 | 2" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 3/16" | 700 | 1 7/16" | 1 3/4" | Ball Up, Ball Down, Angled | 3/8"-16 | 1" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 500 | 1 1/4" | 1 1/2" | Ball Up, Ball Down | 5/16"-18 | 3/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 3/16" | 900 | 2" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 1" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 3/16" | 700 | 2" | 1 3/4" | Ball Up, Ball Down | 3/8"-16 | 1" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||