Matching Flow Diagrams to Replace an Air Directional Control Valve

More

Choosing an Air Directional Control Valve

More

About On/Off Valves

More

Single-Action Air Directional Control Valves

Manually control these valves by pushing or turning the actuator. Also known as 3-way or 3/2 valves, they create one action, such as extending a cylinder. They direct airflow from the inlet to your equipment and exhaust return airflow to create motion. In the off position, they exhaust air pressure from the system, allowing equipment to reset so the action can be repeated.

Normally closed valves block airflow until actuated.

Valves with hand return actuation stay actuated and go back to their starting position only when you move the actuator again. Valves with spring return actuation go back to their starting position as soon as you release the actuator.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

Overall | For Panel Cutout | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Flow Ports | Inlet Size | Outlet Size | Exhaust Connection Type | Max. Flow Rate, scfm @ 100 psi | Flow Coefficient (Cv) | Pressure Range, psi | Vacuum Rating, in. of Hg | Lg. | Wd. | Ht. | Dia. | Mounting Fasteners Included | Each | ||

Normally Closed Flow Positions | |||||||||||||||

Hand Return Actuation | |||||||||||||||

| D | 3 | 10-32 UNF | 10-32 UNF | Threaded | 16.2 | 0.25 | 0-125 | 26 | 5/8" | 5/8" | 2 1/8" | 1/2" | Yes | 0000000 | 000000 |

Spring Return Actuation | |||||||||||||||

| D | 3 | 10-32 UNF | 10-32 UNF | Threaded | 16.2 | 0.25 | 0-125 | 26 | 5/8" | 5/8" | 2 1/8" | 1/2" | Yes | 0000000 | 00000 |

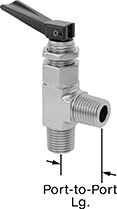

Fast-Acting Panel-Mount Threaded On/Off Valves

Start or stop flow with the flip of a toggle switch or the push of a button. These valves are often used in testing and sampling applications where you need to dispense a small amount of liquid. They fit through a cutout, so the body of the valve stays safe inside your instrumentation panel.

316 stainless steel valves stand up to corrosion better than both plain and nickel-plated brass valves.

Manual-return valves stay open until you flip the toggle off. Since they don't need to be held open, they’re often used to dispense larger samples than spring-return valves. It’s also easy to check if these valves are open or not based on the toggle’s position.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: PTFE Plastic Seal

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: PTFE Plastic Seal

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Return Actuation | Toggle Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

NPT Male × NPT Male | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 0.2 | 300 psi @ 200° F | -20° to 200° | Manual | Plastic | 1" | 17/32" | 0000000 | 0000000 |

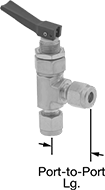

Fast-Acting Panel-Mount On/Off Valves with Yor-Lok Fittings

- Valve Type: Stem

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

Flip the toggle to quickly turn these valves on and off. All have threads and a hex nut below the handle for installation in instrument panels. For extra gripping power and a strong seal, they have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings.

316 stainless steel valves are more corrosion resistant than brass valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Straight | 90° Elbow | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Panel Cutout Dia. | End-to-End Lg. | Each | Port-to-Port Lg. | Each | ||

316 Stainless Steel Body | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/8" | 0.1 | 300 psi @ 200° F | -20° to 200° | 17/32" | 1 15/16" | 0000000 | 0000000 | __ | 000000 | 00 |

| 1/4" | 0.2 | 300 psi @ 200° F | -20° to 200° | 17/32" | 2 1/4" | 0000000 | 000000 | 1 1/8" | 0000000 | 0000000 |