Filter by

Material

Color

Washer Type

Edge Type

Performance

Maximum Temperature

System of Measurement

Minimum Temperature

Export Control Classification Number (ECCN)

REACH

RoHS

DFARS Specialty Metals

Hardness

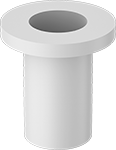

Insulating Sleeve Washers

Cover screw threads to stop electrical current in its tracks and prevent short circuits. These washers create a barrier between the screw threads and the mating surface when mounted in through holes. This barrier also extends the life of your assembly by preventing galvanic corrosion, which is when two different metals rust more quickly due to contact with each other.

Flat Edge

|

The flat edge distributes weight evenly to take pressure off screw heads.

Hard Fiber—The least likely to scratch or mar delicate mounting surfaces, such as printed circuit boards. These washers provide a moderate amount of electrical insulation, but they don't block current as well as plastic or ceramic washers.

Sleeve | Temp. Range | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | Ht. | OD | ID | OD | Thk. | Overall Ht. | Min. | Max., ° F | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard Fiber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 | 0.025" | 0.154" | 0.090" | 0.250" | 0.030" | 0.055" | Not Rated | 230 | Black | 50 | 93920A110 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.025" | 0.186" | 0.116" | 0.250" | 0.030" | 0.055" | Not Rated | 230 | Black | 50 | 93920A120 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.030" | 0.186" | 0.142" | 0.313" | 0.040" | 0.070" | Not Rated | 230 | Black | 50 | 93920A130 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.030" | 0.246" | 0.168" | 0.375" | 0.040" | 0.070" | Not Rated | 230 | Black | 50 | 93920A140 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.030" | 0.312" | 0.194" | 0.375" | 0.040" | 0.070" | Not Rated | 230 | Black | 50 | 93920A150 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.030" | 0.312" | 0.254" | 0.500" | 0.040" | 0.070" | Not Rated | 230 | Black | 50 | 93920A160 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.040" | 0.437" | 0.380" | 0.625" | 0.060" | 0.100" | Not Rated | 230 | Black | 50 | 93920A170 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||