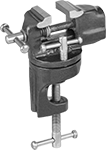

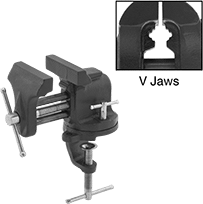

Miniature Clamp-On Bench Vises

Hold your smallest workpieces with these vises, which have a clamp-on base for quick installation and removal from a benchtop.

Vises with a swivel base rotate 180° and can be locked in place.

Jaw | Overall | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Max. Opening | Material | Texture | Replaceable | Throat Dp. | Lg. | Wd. | Ht. | Wt., lbs. | For Max. Mounting Surface Thick. | Mounting Fasteners Included | No. of | Dia. | Each | |

With Flat Jaws | |||||||||||||||

180° Swivel Base | |||||||||||||||

| 1 1/2" | 1" | Steel | Smooth | No | 3/4" | 4" | 2 1/4" | 4 1/4" | 1.7 | 1 1/2" | __ | __ | __ | 0000000 | 000000 |

Fixed Base | |||||||||||||||

| 1 3/32" | 1" | Iron | Smooth | No | 5/16" | 4 1/2" | 1 1/4" | 3" | 1 | 1" | No | 2 | 3/16" | 0000000 | 0000 |

| 1 3/4" | 1 1/4" | Steel | Smooth | No | 3/4" | 3 1/2" | 1 3/4" | 4 1/4" | 1.3 | 1 1/2" | __ | __ | __ | 0000000 | 00000 |

| 2 3/16" | 1 1/4" | Steel | Smooth | No | 3/4" | 3 1/2" | 2 1/4" | 4 1/4" | 1.4 | 1 1/2" | __ | __ | __ | 0000000 | 00000 |

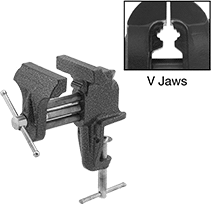

Clamp-On Bench Vises

Designed for portability and space-saving, these vises have a clamp-on base for quick installation and removal from a benchtop. The base also swivels and can be locked in place.

Vises with flat and V jaws (also known as pipe jaws) have a second set of jaws that securely grip pipe and other round objects.

Vises | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flat Jaw | Overall | Mounting Holes | Replacement Flat Jaws | |||||||||||||||

| Wd. | Max. Opening | Material | Texture | V Jaw For Dia. | Throat Dp. | Lg. | Wd. | Ht. | Wt., lbs. | For Max. Mounting Surface Thick. | Mounting Fasteners Included | No. of | Flat Jaw Dia. | V Jaw Dia. | Each | Each | ||

With Flat Jaws | ||||||||||||||||||

45° Swivel Base | ||||||||||||||||||

| 2 1/2" | 2 1/8" | Steel | Grooved | __ | 1 3/4" | 10" | 10 1/4" | 5 1/2" | 11 | 3" | __ | __ | __ | __ | 000000 | 0000000 | 0000000 | 000000 |

| 4" | 2 1/4" | Steel | Grooved | __ | 2" | 10" | 10 1/4" | 5 1/2" | 18 | 3" | __ | __ | __ | __ | 000000 | 000000 | 0000000 | 00000 |

With Flat and V Jaws | ||||||||||||||||||

Fixed Base | ||||||||||||||||||

| 3" | 2 1/2" | Iron | Smooth | 3/8"-2" | 2 5/8" | 6" | 6" | 6" | 4 | 2" | No | 2 | 3/16" | __ | 000000 | 00000 | 000000 | 00 |

360° Swivel Base | ||||||||||||||||||

| 3" | 2 1/2" | Iron | Smooth | 3/8"-2" | 2 5/8" | 6" | 6" | 6" | 6 | 1 7/8" | No | 2 | 1/4" | 5/16" | 000000 | 00000 | 000000 | 00 |

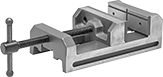

Any-Orientation Drill-Press Vises

The base and three sides of the vise are ground flat, enabling mounting on its base, either side, or upright. Secure directly to your drill press with setup clamps (not included) for drilling, tapping, and reaming applications. Turn the threaded main screw to move the jaw. The open base allows you to drill through the workpiece without hitting the bottom of the vise.

Vises with a smooth and grooved jaw clamp flat, round, and uneven workpieces.

Jaw | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Max. Opening | Style | Material | Texture | Overall Ht. | Body Lg. | Each | |

Fixed Base | |||||||||

| 1 1/2" | 1" | 1 1/2" | Flat | Steel | Smooth and Grooved | 1 7/8" | 5 1/8" | 000000 | 000000 |

| 2 7/16" | 1 1/2" | 3" | Flat | Steel | Smooth and Grooved | 2 5/8" | 7 1/2" | 000000 | 000000 |

| 3" | 1 3/4" | 3" | Flat | Steel | Smooth | 3" | 9" | 000000 | 000000 |

| 4" | 1 3/4" | 4" | Flat | Steel | Smooth and Grooved | 3 1/4" | 10 3/4" | 000000 | 000000 |

| 6" | 2" | 6" | Flat | Steel | Smooth and Grooved | 3 1/2" | 11 3/8" | 0000000 | 000000 |

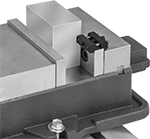

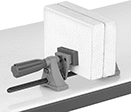

Clamp-On Workstops for Machine Vises

Mount to your vise jaws to create a stop for positioning parts. Turn the spring-loaded screw to adjust and secure on the jaws.

| For Jaw Thick. | Lg. | Wd. | Ht. | Material | Each | |

| 1/2"-1" | 1 7/16" | 1" | 1/2" | Steel | 00000000 | 000000 |

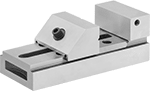

Ultra-Precision Machine Vises

Designed for precision grinding and inspection, the construction of these vises ensures workpieces are held perfectly square. To move the jaw, remove the screw using a 1/4" hex key (not included) and manually slide the jaw into position. Then replace the screw and tighten to firmly grip the workpiece. The base and three sides of the vise are ground flat to a parallel tolerance of 0.0002", enabling mounting on its base, either side, or upright. Mount through the base with screws or use setup clamps (not included). Vises can be used on Bridgeport-style milling machines as well as drill presses and surface grinders. They are also known as toolmakers’ vises.

Jaw | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Max. Opening | Style | Material | Texture | Parallel Tolerance | Overall Ht. | Body Lg. | Base/Bed Parallel Tolerance | Mounting Fasteners Included | No. of | Dia. | Each | |

Fixed Base | ||||||||||||||

| 3" | 1 5/16" | 4 3/4" | Flat | Steel | Smooth and Grooved | 0.0002" | 2 5/8" | 7 1/2" | 0.0002" | No | 4 | 5/16" | 0000000 | 0000000 |

Ball-Grip Positioning Arms

Ball-and-socket connections allow 360° positioning. Choose a complete arm or select a base, connectors, and accessories to build your own.

To ensure compatibility, select components that have the same ball diameter. Use reducing connectors (sold separately) to pair components with a 1 1/2" ball diameter to those with a 1" ball diameter.

Style A bases have a handle to quickly grip or release pipes.

Base | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Style | Clamping Range | Ht. | Ball Dia. | Max. Load Capacity, lbs. | Material | Ball Material | Lg. | Wd. | Each | |

Pipe Mount | ||||||||||

| A | 5/8"-1 1/8" | 4 3/16" | 1" | 1 | Plastic | Rubber | __ | 1 7/16" | 00000000 | 000000 |

| A | 5/8"-1 1/8" | 4 1/4" | 1 1/2" | 3 | Plastic | Rubber | __ | 1 7/16" | 00000000 | 00000 |

| B | 1"-1 1/4" | 3" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | 2 3/8" | 7/8" | 0000000 | 00000 |

| C | 2"-2 1/2" | 3 1/2" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | 4" | 2 1/8" | 00000000 | 00000 |

Rectangular-Bar Mount | ||||||||||

| D | 0"-2 1/2" | 2 1/2" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | 3 1/8" | 1 1/4" | 0000000 | 00000 |

| D | 0"-3" | 4 11/16" | 1" | 1 | Powder-Coated Aluminum | Rubber | 4 7/8" | 1 13/16" | 00000000 | 00000 |

| D | 0"-4" | 5 7/16" | 1 1/2" | 3 | Powder-Coated Aluminum | Rubber | 5 7/8" | 2 9/16" | 00000000 | 00000 |

| D | 0"-4" | 8 5/16" | 2 1/4" | 6 | Powder-Coated Aluminum | Rubber | 5 13/16" | 2 9/16" | 00000000 | 00000 |

Heavy Duty Positioning Arms

Pole Base, Pole, Pole-to-Pin Adapter, Two

Rigid Connectors, and Pivoting Mounting Plate

Heavy duty construction adds strength for higher load capacities than other positioning arms. Choose a complete arm or select a base, connectors, and plate, bracket, or tray to build a complete arm. The load capacity of an assembled arm is determined by the component with the lowest capacity.

| Lg. | Wd. | Ht. | For Pin Dia. | For Pole Dia. | Max. Load Capacity, lbs. | Material | Color | Each | |

Clamp-On Adapter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 4 5/8" | 2 15/16" | 2 3/8" | 7/8" | 2" | 100 | Anodized Aluminum | Black | 00000000 | 000000 |

| 4 5/8" | 2 15/16" | 2 5/8" | 7/8" | 1 1/2" | 100 | Anodized Aluminum | Black | 0000000 | 000000 |

Clamp-On Adapter with Quick-Adjust Lever | |||||||||

| 7 13/16" | 5 5/16" | 3 7/16" | 7/8" | 2" | 100 | Powder-Coated Steel | Black | 0000000 | 000000 |

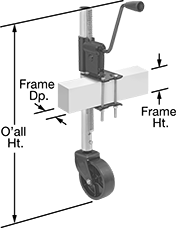

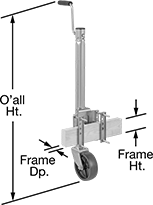

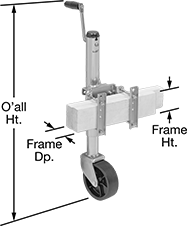

Leveling Jacks with Wheel

Mount these jacks to equipment to raise and level it. A swivel caster lets you reposition your load.

Side Mount—Slide the frame of your equipment through the mounting plate.

Locking pin locks the jack in a vertical position; pull the pin to rotate the jack into a horizontal position when not in use.

Warning: Never use to support people or loads over people.

Capacity | For Frame | Mounting | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Ht. | Max. Lift | O'all Ht. | Ht. | Dp. | Handle Lg. | Body Material | Fasteners Included | Wheel Material | Each | ||

Side Mount | |||||||||||||

| A | 1/4 | 750 | 7 1/2"-23 1/2" | 16" | 27 7/8" | 0"-5" | 1 7/8"-2 7/8" | 5 1/2" | Steel | Yes | Plastic | 000000 | 0000000 |

| B | 1/2 | 1,000 | 10 13/16"-25 1/2" | 14 11/16" | 33 7/8" | 3"-5" | 2"-3" | 6 1/8" | Steel | Yes | Plastic | 0000000 | 000000 |

Side Mount with Locking Pin | |||||||||||||

| C | 1/2 | 1,200 | 12 1/2"-22 1/2" | 10" | 28 1/8" | 2"-4" | 1 1/2"-3" | 6" | Steel | Yes | Plastic | 0000000 | 000000 |

| C | 3/4 | 1,500 | 12 7/8"-22 7/8" | 10" | 31 5/8" | 3"-5" | 2"-3" | 6 1/8" | Steel | Yes | Plastic | 0000000 | 000000 |

Bench Vises for Dremel

Free up a hand while using your Dremel on a workpiece. You can use these vises in three different ways: hold your Dremel to make it a stationary tool, secure your workpiece in the vise, or remove the clamp and use it on its own. These vises rotate 360° and tilt, so you can work on your project from any angle.

Jaw | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Max. Opening | Material | Texture | Throat Dp. | Lg. | Wd. | Ht. | Wt., lbs. | For Max. Mounting Surface Thick. | For Manufacturer Model No. | Features | Includes | Each | |

With Flat Jaws | ||||||||||||||

360° Swivel Base | ||||||||||||||

| 7 1/2" | 7" | Rubber | Grooved | 2 1/4" | 13" | 4 1/4" | 13" | 2.7 | 2 1/2" | 100, 100-N/7, 200, 285, 300, 3000, 3000-1/24, 395, 400, 4000, 4000-2/30, 4200, 800, 8100-N/21, 8200, 8220, 8220-1/28 | Removable Clamp | Tool Holder Ring | 0000000 | 000000 |

Pipettor Holders

Store pipettors to keep your lab organized. These holders keep pipettors upright, preventing liquid from running upward—which can cause damage.

Clamp-on-mount holders come with two extenders for a total capacity of three pipettors. Add more extenders (sold separately) for even greater capacity.

Flashlight Mounts

Free your hands for other work by mounting a flashlight (not included) to a nearby surface.

Clamp-on mounts hug table edges and other surfaces up to 2" thick. Tighten them as needed for a secure hold.