About Flanged Flow-Adjustment Valves

More

About On/Off Valves

More

About Actuated On/Off Valves

More

High-Pressure Compact Threaded On/Off Valves

These valves handle twice the pressure of other compact valves. Install them in tight spots, such as where pipelines are crowded together. They’re roughly half the height and length of standard threaded valves.

316 stainless steel valves resist corrosion better than brass and steel valves.

Lockable handles can be fixed in place using a padlock (not included).

Full-port valves do not restrict flow. Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating | Port Type | End-to-End Lg. | Each | |

NPT Female × NPT Female | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 × 1/4 | 1.3 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2" | 00000000 | 000000 |

| 3/8 × 3/8 | 2.6 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2 3/8" | 00000000 | 00000 |

| 1/2 × 1/2 | 9.2 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2 15/16" | 00000000 | 00000 |

| 3/4 × 3/4 | 12.6 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2 5/16" | 00000000 | 00000 |

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Each | |

NPT Female × NPT Female | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 × 1/4 | 8.2 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Full | 2 13/16" | 9/32" | 000000000 | 000000 |

| 3/8 × 3/8 | 6.7 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Standard | 2 13/16" | 9/32" | 000000000 | 00000 |

| 1/2 × 1/2 | 5.7 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Standard | 3 3/8" | 9/32" | 000000000 | 00000 |

NPT Female × NPT Male | |||||||||

| 1/4 × 1/4 | 8.2 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Full | 2 13/16" | 9/32" | 000000000 | 00000 |

| 3/8 × 3/8 | 6.7 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Standard | 2 13/16" | 9/32" | 000000000 | 00000 |

| 1/2 × 1/2 | 5.7 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Standard | 3 3/8" | 9/32" | 000000000 | 00000 |

NPT Male × NPT Male | |||||||||

| 1/4 × 1/4 | 8.2 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Full | 2 3/4" | 9/32" | 000000000 | 00000 |

| 3/8 × 3/8 | 6.7 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Standard | 2 3/4" | 9/32" | 000000000 | 00000 |

| 1/2 × 1/2 | 5.7 | 1000 psi @ 100° F | 0° to 370° | 29.9 | Standard | 3 7/16" | 9/32" | 000000000 | 00000 |

On/Off Valves with Yor-Lok Fittings

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Valves are standard port, so they slightly restrict flow.

316 stainless steel valves are more corrosion resistant than plain and nickel-plated brass valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

Yor Lok × Yor Lok | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 0000000 | 000000 |

| 3/8" | 2.5 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 0000000 | 00000 |

| 1/2" | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 3/4" | 0000000 | 000000 |

| 3/4" | 12.65 | 2000 psi @ 100° F | -30° to 400° | 4 7/16" | 00000000 | 000000 |

| 1" | 17.35 | 2000 psi @ 100° F | -30° to 400° | 5 1/8" | 00000000 | 000000 |

| 6mm | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 00000000 | 00000 |

| 8mm | 1.35 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 00000000 | 000000 |

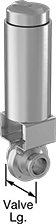

Sanitary Air-Driven On/Off Valves

- For Use With: Air, Argon, Beverage, Carbon Dioxide, Citric Acid, Drinking Water, Ethanol, Food, Helium, Isopropyl Alcohol, Methanol, Mineral Oils, Natural Gas, Neon, Nitrogen, Oil, Oxygen, Salt Water, Soap Solutions, Sodium Hypochlorite, Steam, Water, Xenon

- Seal Material: Silicone Rubber

- Specifications Met: FDA Compliant 21 CFR 177.2600

Use air pressure to automatically control the flow of liquids in sanitary environments, such as food and beverage processing plants. These valves connect to your liquid line with quick-clamp sanitary fittings, also known as tri-clamp connections, which are easier to remove and sanitize than threaded connections. You’ll need a gasket and clamp to connect them to another quick-clamp fitting (not included). They are also self-draining, so liquids drain completely and don’t pool on actuators or valves. The polished interior is extremely smooth, so there’s nowhere for bacteria to hide. Made of stainless steel, these valves won’t corrode from frequent washdowns with harsh cleaners. Their seal is FDA compliant for direct contact with food.

They are single-acting actuators, which open from the force of compressed air and close with an internal spring. You’ll also need either an electric pilot valve or a manual on/off valve (not included) to control the air flowing to the actuator. They open and close faster than motor driven valves and can be operated remotely, so they’re often used in automated liquid lines. Since they are normally closed unless air pressure opens them, these valves will stop the flow if there is a power outage or the air supply is cut. There must be a minimum pressure drop between the inlet and the outlet for these valves to work, meaning that the upstream pressure must be greater than the downstream pressure.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Actuator repair kits include replacements for all parts inside the actuator.

Valves | Actuator Repair Kits | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Gender | Connection Style | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | Valve Lg. | Overall Ht. | For Air Connection Tube OD, mm | Air Connection Gender | Air Pressure Range, psi | Each | Each | ||

316 Stainless Steel Body | ||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed) | ||||||||||||||

| 1" | Female | Quick Clamp | 27 | 120 psi @ 70° F | -40° to 450° | 2 11/16" | 14" | 6 | Female | 70 to 115 | 0000000 | 0000000 | 0000000 | 000000 |

| 1 1/2" | Female | Quick Clamp | 92 | 120 psi @ 70° F | -40° to 450° | 3" | 14 13/16" | 6 | Female | 70 to 115 | 0000000 | 000000 | 0000000 | 00000 |

| 2" | Female | Quick Clamp | 248 | 120 psi @ 70° F | -40° to 450° | 3 1/8" | 15 1/8" | 6 | Female | 70 to 115 | 0000000 | 000000 | 0000000 | 00000 |

| 3" | Female | Quick Clamp | 411 | 120 psi @ 70° F | -40° to 450° | 3 1/4" | 15 3/4" | 6 | Female | 70 to 115 | 0000000 | 00000000 | 0000000 | 00000 |

| 4" | Female | Quick Clamp | 880 | 120 psi @ 70° F | -40° to 450° | 3 1/2" | 17" | 6 | Female | 70 to 115 | 0000000 | 00000000 | 0000000 | 00000 |

Flow-Adjustment Valves with Sanitary

Quick-Clamp Fittings for Food and Beverage

- Valve Type: Butterfly

- For Use With: Food, Beverage

To maintain sanitary standards in food and beverage applications, these valves have internal surfaces that prevent product buildup and inhibit bacteria growth. All have sanitary quick-clamp fittings for easy disassembly in systems that require frequent cleaning. They gradually open and close to adjust and regulate flow.

304 stainless steel valves have good corrosion resistance.

316 stainless steel valves have the best corrosion resistance.

Lever handles have 4 flow-adjustment positions.

Lockable lever handles have 12 flow-adjustment positions. The handle can be fixed in place using a padlock (not included) with a shackle diameter up to 1/4”.

Silicone seats have some resistance to organic food acids and fats and oils.

EPDM seats have good resistance to organic food acids. They have poor resistance to fats and oils.

Fluoroelastomer seats have excellent resistance to many food-processing chemicals and good resistance to organic food acids and fats and oils.

PTFE seats have the best resistance to a broad range of food-processing chemicals, organic food acids, and fats and oils.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Lever Handle | Lockable Lever Handle | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | O'all Ht. | O'all Lg. | Each | O'all Ht. | O'all Lg. | For Max. Shackle Dia. | Each | ||

304 Stainless Steel Body—Silicone Rubber Seat (FDA Compliant 21 CFR 177.2600) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 145 psi @ 450° F | -80° to 450° | 2 11/16" | 5 3/8" | 7 15/16" | 00000000 | 0000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 0000000 |

| 1 1/2" | 2" | 92 | 145 psi @ 450° F | -80° to 450° | 3" | 5 5/8" | 8 1/8" | 00000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 145 psi @ 450° F | -80° to 450° | 3 1/8" | 6 3/8" | 8 3/16" | 00000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 145 psi @ 450° F | -80° to 450° | 3 1/8" | 6 11/16" | 8 3/16" | 00000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 145 psi @ 450° F | -80° to 450° | 3 1/4" | 7 3/16" | 8 1/4" | 00000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 145 psi @ 450° F | -80° to 450° | 3 1/2" | 8 7/16" | 8 3/8" | 00000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

304 Stainless Steel Body—EPDM Rubber Seat (FDA Compliant 21 CFR 177.2600) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 145 psi @ 300° F | -60° to 300° | 2 11/16" | 5 3/8" | 7 15/16" | 000000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 145 psi @ 300° F | -60° to 300° | 3" | 5 5/8" | 8 1/8" | 000000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 145 psi @ 300° F | -60° to 300° | 3 1/8" | 6 3/8" | 8 3/16" | 000000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 145 psi @ 300° F | -60° to 300° | 3 1/8" | 6 11/16" | 8 3/16" | 000000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 145 psi @ 300° F | -60° to 300° | 3 1/4" | 7 3/16" | 8 1/4" | 000000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 145 psi @ 300° F | -60° to 300° | 3 1/2" | 8 7/16" | 8 3/8" | 000000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

304 Stainless Steel Body—Fluoroelastomer Rubber Seat (FDA Compliant 21 CFR 177.2600) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 145 psi @ 400° F | -20° to 400° | 2 11/16" | 5 3/8" | 7 15/16" | 00000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 145 psi @ 400° F | -20° to 400° | 3" | 5 5/8" | 8 1/8" | 00000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 145 psi @ 400° F | -20° to 400° | 3 1/8" | 6 3/8" | 8 3/16" | 00000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 145 psi @ 400° F | -20° to 400° | 3 1/8" | 6 11/16" | 8 3/16" | 00000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 145 psi @ 400° F | -20° to 400° | 3 1/4" | 7 3/16" | 8 1/4" | 00000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 145 psi @ 400° F | -20° to 400° | 3 1/2" | 8 7/16" | 8 3/8" | 00000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

304 Stainless Steel Body—PTFE Plastic Seat (FDA Compliant 21 CFR 177.1550) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 60 psi @ 450° F | -40° to 450° | 2 11/16" | 5 3/8" | 7 15/16" | 000000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 60 psi @ 450° F | -40° to 450° | 3" | 5 5/8" | 8 1/8" | 000000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 60 psi @ 450° F | -40° to 450° | 3 1/8" | 6 3/8" | 8 3/16" | 000000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 60 psi @ 450° F | -40° to 450° | 3 1/8" | 6 11/16" | 8 3/16" | 000000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 60 psi @ 450° F | -40° to 450° | 3 1/4" | 7 3/16" | 8 1/4" | 000000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 60 psi @ 450° F | -40° to 450° | 3 1/2" | 8 7/16" | 8 3/8" | 000000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

316 Stainless Steel Body—Silicone Rubber Seat (FDA Compliant 21 CFR 177.2600) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 145 psi @ 450° F | -80° to 450° | 2 11/16" | 5 3/8" | 8 11/16" | 0000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 145 psi @ 450° F | -80° to 450° | 3" | 5 5/8" | 8 5/8" | 0000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 145 psi @ 450° F | -80° to 450° | 3 1/8" | 6 3/8" | 9" | 0000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 145 psi @ 450° F | -80° to 450° | 3 1/8" | 6 11/16" | 9 3/16" | 0000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 145 psi @ 450° F | -80° to 450° | 3 1/4" | 7 3/16" | 9 1/2" | 0000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 145 psi @ 450° F | -80° to 450° | 3 1/2" | 8 7/16" | 10 1/16" | 0000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

316 Stainless Steel Body—EPDM Rubber Seat (FDA Compliant 21 CFR 177.2600) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 145 psi @ 300° F | -60° to 300° | 2 11/16" | 5 3/8" | 8 11/16" | 00000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 145 psi @ 300° F | -60° to 300° | 3" | 5 5/8" | 8 5/8" | 00000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 145 psi @ 300° F | -60° to 300° | 3 1/8" | 6 3/8" | 9" | 00000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 145 psi @ 300° F | -60° to 300° | 3 1/8" | 6 11/16" | 9 3/16" | 00000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 145 psi @ 300° F | -60° to 300° | 3 1/4" | 7 3/16" | 9 1/2" | 00000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 145 psi @ 300° F | -60° to 300° | 3 1/2" | 8 7/16" | 10 1/16" | 00000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

316 Stainless Steel Body—Fluoroelastomer Rubber Seat (FDA Compliant 21 CFR 177.2600) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 145 psi @ 400° F | -20° to 400° | 2 11/16" | 5 3/8" | 8 11/16" | 0000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 145 psi @ 400° F | -20° to 400° | 3" | 5 5/8" | 8 5/8" | 0000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 145 psi @ 400° F | -20° to 400° | 3 1/8" | 6 3/8" | 9" | 0000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 145 psi @ 400° F | -20° to 400° | 3 1/8" | 6 11/16" | 9 3/16" | 0000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 145 psi @ 400° F | -20° to 400° | 3 1/4" | 7 3/16" | 9 1/2" | 0000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 145 psi @ 400° F | -20° to 400° | 3 1/2" | 8 7/16" | 10 1/16" | 0000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

316 Stainless Steel Body—PTFE Plastic Seat (FDA Compliant 21 CFR 177.1550) | ||||||||||||||

Quick Clamp × Quick Clamp | ||||||||||||||

| 1" | 2" | 27 | 60 psi @ 450° F | -40° to 450° | 2 11/16" | 5 3/8" | 8 11/16" | 00000000 | 000000 | 5 1/16" | 8 1/16" | 1/4" | 00000000 | 000000 |

| 1 1/2" | 2" | 92 | 60 psi @ 450° F | -40° to 450° | 3" | 5 5/8" | 8 5/8" | 00000000 | 000000 | 5 1/4" | 8 3/16" | 1/4" | 00000000 | 000000 |

| 2" | 2 33/64" | 248 | 60 psi @ 450° F | -40° to 450° | 3 1/8" | 6 3/8" | 9" | 00000000 | 000000 | 6 1/16" | 8 9/16" | 1/4" | 00000000 | 000000 |

| 2 1/2" | 3 1/16" | 287 | 60 psi @ 450° F | -40° to 450° | 3 1/8" | 6 11/16" | 9 3/16" | 00000000 | 000000 | __ | __ | __ | 000000 | 00 |

| 3" | 3 9/16" | 411 | 60 psi @ 450° F | -40° to 450° | 3 1/4" | 7 3/16" | 9 1/2" | 00000000 | 000000 | 6 13/16" | 8 15/16" | 1/4" | 00000000 | 000000 |

| 4" | 4 11/16" | 880 | 60 psi @ 450° F | -40° to 450° | 3 1/2" | 8 7/16" | 10 1/16" | 00000000 | 000000 | 8 1/8" | 9 5/8" | 1/4" | 00000000 | 000000 |

| Material | Each | |

| PTFE Plastic | 00000000 | 00000 |

| For Tube OD | Each | |

Silicone Rubber | ||

|---|---|---|

| 1" | 0000000 | 000000 |

| 1 1/2" | 0000000 | 00000 |

| 2" | 0000000 | 00000 |

| 2 1/2" | 0000000 | 00000 |

| 3" | 0000000 | 00000 |

| 4" | 0000000 | 00000 |

EPDM Rubber | ||

| 1" | 0000000 | 00000 |

| 1 1/2" | 0000000 | 00000 |

| 2" | 0000000 | 00000 |

| 2 1/2" | 0000000 | 00000 |

| 3" | 0000000 | 00000 |

| 4" | 0000000 | 00000 |

Fluoroelastomer Rubber | ||

| 1" | 0000000 | 00000 |

| 1 1/2" | 0000000 | 00000 |

| 2" | 0000000 | 00000 |

| 2 1/2" | 0000000 | 000000 |

| 3" | 0000000 | 000000 |

| 4" | 0000000 | 000000 |

PTFE Plastic | ||

| 1" | 0000000 | 00000 |

| 1 1/2" | 0000000 | 00000 |

| 2" | 0000000 | 00000 |

| 2 1/2" | 0000000 | 00000 |

| 3" | 0000000 | 00000 |

| 4" | 0000000 | 000000 |

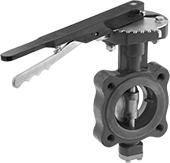

Flanged Flow-Adjustment Valves

Also known as butterfly valves, these bolt to flanges for adjusting and regulating flow in flanged pipelines.

Lug valves can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Lockable lever handles can be fixed in place with a padlock (not included).

316 stainless steel valves are more corrosion resistant than ductile iron valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Butterfly

- For Use With: See table

- Specifications Met: See table

| Pipe Size | For Max. Shackle Dia. | For Use With | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

316 Stainless Steel Body—316 Stainless Steel Disc | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 3/16" | Water, Oil, Air | 125, 150 | 6" | 4 3/4" | 4 | 3/4" | No | 277 | 150 psi @ 210° F | 0° to 210° | 1 13/16" | 0000000 | 0000000 |

| 2 | 3/16" | Water, Air | 125, 150 | 6" | 4 3/4" | 4 | 3/4" | No | 277 | 150 psi @ 250° F | -40° to 250° | 1 13/16" | 0000000 | 000000 |

| 3 | 3/16" | Water, Oil, Air | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 720 | 150 psi @ 210° F | 0° to 210° | 2 1/16" | 0000000 | 000000 |

| 3 | 3/16" | Water, Air | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 720 | 150 psi @ 250° F | -40° to 250° | 2 1/16" | 0000000 | 000000 |

| 4 | 3/16" | Water, Oil, Air | 125, 150 | 9" | 7 1/2" | 8 | 3/4" | No | 1,366 | 150 psi @ 210° F | 0° to 210° | 2 5/16" | 0000000 | 000000 |

| 4 | 3/16" | Water, Air | 125, 150 | 9" | 7 1/2" | 8 | 3/4" | No | 1,366 | 150 psi @ 250° F | -40° to 250° | 2 5/16" | 0000000 | 000000 |

| 6 | 3/16" | Water, Oil, Air | 125, 150 | 11" | 9 1/2" | 8 | 3/4" | No | 2,901 | 150 psi @ 210° F | 0° to 210° | 2 7/16" | 0000000 | 00000000 |

| 6 | 3/16" | Water, Air | 125, 150 | 11" | 9 1/2" | 8 | 3/4" | No | 2,901 | 150 psi @ 250° F | -40° to 250° | 2 7/16" | 0000000 | 00000000 |

Extended-Life Flanged Flow-Adjustment Valves

- Valve Type: Butterfly

- For Use With: Water, Air, Argon, Helium, Krypton, Neon, Steam, Xenon

- Specifications Met: API 609, ASME B16.34, ASME B16.5, MSS-SP-25, MSS-SP-61, MSS-SP-68

For a longer service life than other flanged flow-adjustment valves, these are designed to open and close with minimal wear on internal components. They bolt to flanges for adjusting and regulating flow in flanged pipelines. Fix the lockable lever handle in place using a padlock (not included) with a shackle diameter up to 5/16”. Valves are wafer style, so they must be sandwiched between two flanges; all have grooves to help align the valve between the flanges.

316 stainless steel valves are more corrosion resistant than carbon steel valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Carbon Steel Body—316 Stainless Steel Disc | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 5/16" | 150 | 7 1/2" | 6" | 4 | 3/4" | No | 228 | 285 psi @ 100° F | 50 psi @ 295° F | -20° to 500° | 1 15/16" | 0000000 | 000000000 |

316 Stainless Steel Body—316 Stainless Steel Disc | ||||||||||||||

| 3 | 5/16" | 150 | 7 1/2" | 6" | 4 | 3/4" | No | 228 | 285 psi @ 100° F | 50 psi @ 295° F | -100° to 500° | 1 15/16" | 0000000 | 00000000 |

| 4 | 5/16" | 150 | 9" | 7 1/2" | 8 | 3/4" | No | 451 | 285 psi @ 100° F | 50 psi @ 295° F | -100° to 500° | 2 1/8" | 0000000 | 00000000 |

Flanged Flow-Adjustment Valves for Steam

- Valve Type: Butterfly

- For Use With: Steam

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.34A

Rated for steam pressures up to 100 psi @ 400° F, these valves have PTFE seats for excellent temperature resistance. They bolt to flanges for adjusting and regulating flow in flanged pipelines. These valves are lug style, so they can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Powder-Coated Epoxy Carbon Steel Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Powder-Coated Epoxy CF8M Stainless Steel Disc | ||||||||||||

| 2 | 150 | 6" | 4 3/4" | 4 | 3/4" | No | 92 | 100 psi @ 400° F | -20° to 450° | 1 11/16" | 000000 | 000000000 |

| 3 | 150 | 7 1/2" | 6" | 4 | 3/4" | No | 260 | 100 psi @ 400° F | -20° to 450° | 1 7/8" | 000000 | 00000000 |