Filter by

Wall Thickness

Shape

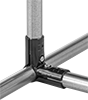

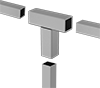

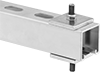

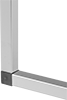

Compatible Fittings

For Use With

DFARS Specialty Metals

Steel Grade

Pipe Material

Internal Reinforcement

For Conduit Material

Frame Material

Reinforcement Material

Fluid Handling

Raw Materials

Electrical

Building and Machinery Hardware

Power Transmission

Heating, Ventilation, and Air Conditioning

Fastening and Joining

Containers, Storage, and Furniture

Facility and Grounds Maintenance

Sealing

Fabricating and Machining

Material Handling