Step Stools

Get a secure and stable step up.

Aluminum stools are the lightest, making them easy to move between work areas. Perforated, coated, and ribbed steps provide good slip resistance while being easy on your shoes. Perforated steps also allow liquids to drain and debris to fall through. Serrated steps provide maximum slip resistance but are uncomfortable to stand on for prolonged periods.

Styles 5, 6, and 9 have nonskid pads that are wider than the nonskid feet on other stools, so they’re less likely to get stuck on bar grating and other surfaces with small openings.

For added stability, Style 17 have leveling feet that help prevent rocking on uneven surfaces.

Stools that comply with OSHA 29 CFR 1910.23 or OSHA 29 CFR 1926.1053 meet standards for ladders.

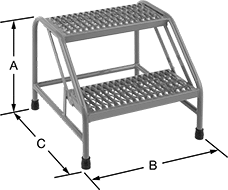

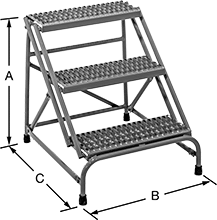

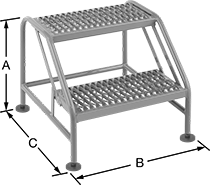

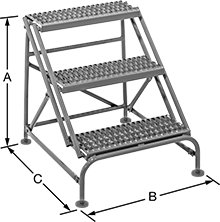

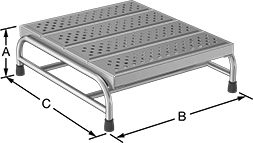

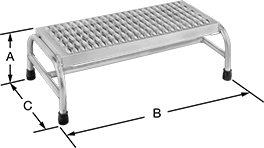

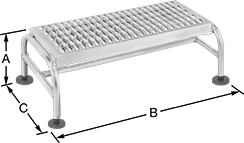

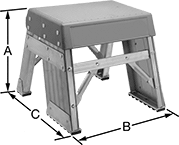

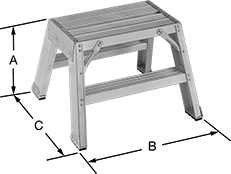

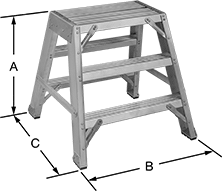

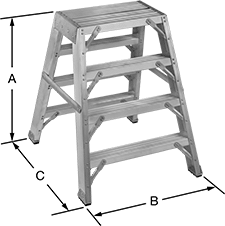

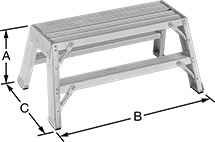

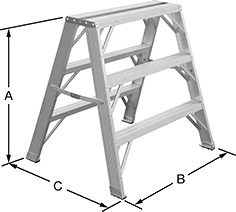

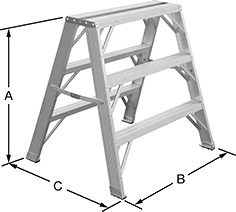

Overall | Top Step | Middle Step | Bottom Step | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Ground Clearance Ht. | Assembled or Unassembled | Color | Features | Specifications Met | Each | |

Powder-Coated Aluminum | |||||||||||||||||||

With Perforated Steps | |||||||||||||||||||

| 7 | 1 | 500 | 9" | 26 1/2" | 28 1/2" | 9" | 24" | 28" | __ | __ | __ | __ | 2 1/2" | Assembled | Yellow | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 0000000 |

With Serrated Steps | |||||||||||||||||||

| 3 | 2 | 500 | 20" | 27" | 22 1/2" | 20" | 24" | 10" | __ | __ | 24" | 10" | 4 1/4" | Assembled | Yellow | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 4 | 3 | 500 | 30" | 28" | 34" | 30" | 24" | 10" | 24" | 10" | 24" | 10" | 2 1/2" | Unassembled | Yellow | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 5 | 2 | 500 | 20" | 28 1/2" | 24" | 20" | 24" | 10" | __ | __ | 24" | 10" | 4 1/4" | Assembled | Yellow | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 6 | 3 | 500 | 30" | 29 1/2" | 35 1/2" | 30" | 24" | 10" | 24" | 10" | 24" | 10" | 2 1/2" | Unassembled | Yellow | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 6 | 3 | 500 | 30" | 34 1/2" | 34" | 30" | 30" | 10" | 30" | 10" | 30" | 10" | 4 1/4" | Assembled | Yellow | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 8 | 1 | 500 | 10" | 33" | 16 1/2" | 10" | 30" | 12" | __ | __ | __ | __ | 3 3/4" | Assembled | Yellow | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 9 | 1 | 500 | 10" | 34 1/2" | 18" | 10" | 30" | 12" | __ | __ | __ | __ | 3 3/4" | Assembled | Yellow | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

Aluminum | |||||||||||||||||||

With Perforated Steps | |||||||||||||||||||

| 7 | 1 | 500 | 9" | 26 1/2" | 28 1/2" | 9" | 24" | 28" | __ | __ | __ | __ | 2 1/2" | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

With Grit-Coated Steps | |||||||||||||||||||

| 10 | 1 | 300 | 12" | 23" | 17" | 12" | 18" | 12" | __ | __ | __ | __ | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

With Ribbed Steps | |||||||||||||||||||

| 11 | 1 | 375 | 13" | 15" | 16" | 13" | 14" | 9 1/4" | __ | __ | __ | __ | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1926.1053 | 00000000 | 000000 |

| 12 | 2 | 300 | 16" | 22" | 21" | 15" | 18" | 10 1/2" | __ | __ | 17" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 12 | 2 | 300 | 18" | 22 1/2" | 21 1/2" | 17" | 18" | 10 3/4" | __ | __ | 17" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 12 | 2 | 300 | 24" | 23 1/2" | 25 1/2" | 23" | 18" | 10 3/4" | __ | __ | 18" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 13 | 3 | 300 | 23" | 24" | 26" | 23" | 18" | 10 1/2" | 17" | 3" | 18 1/2" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 13 | 3 | 300 | 30" | 25" | 28 1/2" | 28" | 18" | 10 3/4" | 17 1/2" | 3" | 19 1/2" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 14 | 4 | 300 | 31" | 25" | 31" | 30" | 18" | 10 1/2" | 17" | 3" | 20 1/2" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 15 | 2 | 300 | 24" | 37 1/2" | 25 1/2" | 23" | 32" | 10 3/4" | __ | __ | 32" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 15 | 2 | 300 | 24" | 53 1/2" | 25 1/2" | 23" | 48" | 10 3/4" | __ | __ | 48" | 3" | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 16 | 1 | 300 | 18" | 52" | 20 1/2" | 17" | 48" | 10 3/4" | __ | __ | __ | __ | __ | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 17 | 1 | 300 | 8" | 20" | 16" | 7" | 18" | 10 3/4" | __ | __ | __ | __ | __ | Assembled | __ | Nonskid Leveling Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 17 | 1 | 300 | 12" | 21" | 18" | 11" | 18" | 10 3/4" | __ | __ | __ | __ | __ | Assembled | __ | Nonskid Leveling Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

| 17 | 1 | 300 | 20" | 37" | 23" | 19" | 32" | 10 3/4" | __ | __ | __ | __ | __ | Assembled | __ | Nonskid Leveling Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.2, Cal/OSHA Compliant Title 8 Section 3276 | 0000000 | 000000 |

With Serrated Steps | |||||||||||||||||||

| 3 | 2 | 500 | 20" | 27" | 23" | 20" | 24" | 9 1/2" | __ | __ | 24" | 9 1/2" | 3 3/4" | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 4 | 3 | 500 | 30" | 28" | 34" | 30" | 24" | 9 1/2" | 24" | 9 1/2" | 24" | 9 1/2" | 3" | Unassembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 4 | 3 | 500 | 30" | 33" | 33" | 30" | 30" | 9 1/2" | 30" | 9 1/2" | 30" | 9 1/2" | 3 3/4" | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 5 | 2 | 500 | 20" | 28 1/2" | 24" | 20" | 24" | 10" | __ | __ | 24" | 10" | 4 1/4" | Assembled | __ | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 6 | 3 | 500 | 30" | 34 1/2" | 34" | 30" | 30" | 10" | 30" | 10" | 30" | 10" | 4 1/4" | Assembled | __ | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 8 | 1 | 500 | 10" | 33" | 17" | 10" | 30" | 11 1/2" | __ | __ | __ | __ | 3 3/4" | Assembled | __ | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

| 9 | 1 | 500 | 10" | 34 1/2" | 18" | 10" | 30" | 12" | __ | __ | __ | __ | 3 3/4" | Assembled | __ | Nonskid Pads | OSHA Compliant 29 CFR 1910.23, ANSI A14.7, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627 | 0000000 | 000000 |

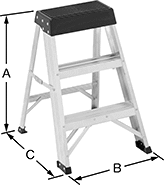

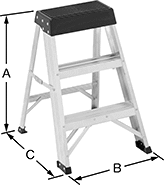

Folding Step Stools

Fold for easy transport and storage.

Aluminum stools are lighter weight than steel and fiberglass, making them easier to move between work areas. Style 2 stools have legs that can adjust to different heights.

Style 4 stools have additional bracing for higher capacities than Style 3, so they’re a more common choice for industrial applications.

Style 5 stools can be climbed from both sides.

Style 6 stools can be used in pairs to create a work surface or scaffold. They have a braced top step that is designed to hold a plank or platform between the pair of stools.

Stools with ribbed steps have good slip resistance and are gentle on your footwear.

Type 1A stools are tested to hold up to 300 lbs. Type 1AA stools are tested to hold up to 375 lbs.

Note: Step stools that meet OSHA or Cal/OSHA specifications adhere to dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

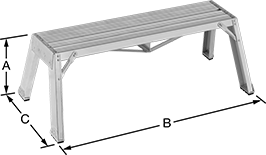

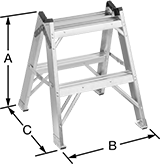

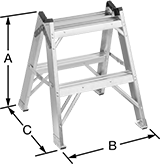

Overall | Top Step | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Assembled or Unassembled | Each | |

Aluminum | ||||||||||

With Ribbed Steps | ||||||||||

| 1 | 1,000 | 7"-8" | 24 1/2" | 20" | 7"-8" | 19" | 14 1/2" | Assembled | 00000000 | 0000000 |

Overall | Top Step | Middle Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Specifications Met | Each | |

Aluminum | ||||||||||||||||

With Ribbed Steps | ||||||||||||||||

| 2 | 375 | Type 1AA | 23" | 18" | 21" | 23" | 14" | 9 1/4" | __ | __ | 17 1/4" | 6" | Assembled | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 00000000 | 0000000 |

| 3 | 300 | Type 1A | 24" | 17" | 19" | 24" | 12" | 6" | 12" | 3" | 13 1/2" | 3" | Assembled | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 0000000 | 00000 |

| 3 | 375 | Type 1AA | 33" | 20" | 27" | 33" | 14" | 9 1/4" | 19 3/4" | 6" | 19 3/4" | 6" | Assembled | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 00000000 | 000000 |

Overall | Top Step | Middle Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Specifications Met | Each | |

Aluminum | ||||||||||||||||

With Ribbed Steps | ||||||||||||||||

| 3 | 300 | Type 1A | 36" | 34" | 29" | 36" | 30" | 8" | 28" | 3 1/4" | 28" | 3" | Assembled | Cal/OSHA Compliant Title 8 Section 3276 ANSI A14.2 ANSI A14.11 | 00000000 | 0000000 |

| 4 | 300 | Type 1A | 48" | 37" | 36" | 48" | 30" | 8" | 28" | 3 1/4" | 28" | 3" | Assembled | Cal/OSHA Compliant Title 8 Section 3276 ANSI A14.2 ANSI A14.11 | 00000000 | 000000 |

Overall | Top Step | Bottom Step | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Specifications Met | Each | |

Aluminum | ||||||||||||||

With Ribbed Steps | ||||||||||||||

| 2 | 300 | Type 1A | 24" | 21" | 23 1/2" | 23" | 14" | 8 1/4" | 14" | 3" | Assembled | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.11 | 0000000 | 0000000 |

Folding Step Stools with Handrail

Grab the handrail for stability. These stools fold for easy transport and storage.

Aluminum stools are lighter than steel and fiberglass, making them easier to move between work areas.Perforated, coated, and ribbed steps provide good slip resistance and are gentle on your footwear.Stools with casters can be moved by tilting them. They remain stationary when upright.

Note: Step stools that meet OSHA or Cal/OSHA specifications adhere to dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating procedures.

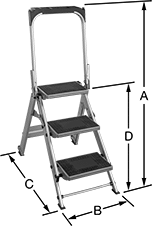

Overall | Top Step | Bottom Step | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. | Dp. | Wd. | Dp. | Wheel Configuration | Specifications Met | Includes | Each | |

Aluminum | ||||||||||||||||

With Rubber-Coated Steps | ||||||||||||||||

| 2 | 2 | 300 | Type 1A | 34" | 21" | 22" | 18" | 14" | 9" | 14" | 9" | Two Rigid Casters | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.2 | __ | 0000000 | 0000000 |

| 2 | 3 | 300 | Type 1A | 51" | 22" | 33" | 26" | 14" | 9" | 14" | 9" | Two Rigid Casters | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.2 | Handrail-Mounted Tool Tray | 0000000 | 000000 |

| 2 | 4 | 300 | Type 1A | 59" | 22" | 46" | 35" | 14" | 9" | 14" | 9" | Two Rigid Casters | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.2 | Handrail-Mounted Tool Tray | 0000000 | 000000 |

With Ribbed Steps | ||||||||||||||||

| 3 | 2 | 375 | Type 1AA | 53" | 18" | 21" | 23" | 14" | 9 1/4" | 17 1/4" | 6" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, ANSI A14.11 | __ | 00000000 | 000000 |

| 3 | 3 | 375 | Type 1AA | 64" | 20" | 27" | 34" | 14" | 9 1/4" | 19 3/4" | 6" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, ANSI A14.11 | __ | 00000000 | 000000 |

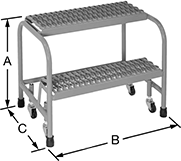

Rolling Step Stools

With spring-loaded casters, these step stools are easy to move between work areas. When you’re on the stool, the casters retract to keep the stool stationary. When you step off, the casters roll again.

Aluminum stools are lighter than steel, making them easier to move.

Perforated, coated, and ribbed steps provide good slip resistance while being easy on your shoes. Serrated steps provide maximum slip resistance but are uncomfortable to stand on for prolonged periods.

Note: Stools that have OSHA or Cal/OSHA specifications listed meet dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Stools | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Top Step | Replacement Casters | Replacement Nonskid Feet | |||||||||||||||||

| Style | No. of Steps | Cap., lbs. | Ht.(A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Ground Clearance Ht. | Assembled or Unassembled | Wheel Configuration | Specifications Met | Each | No. of Casters | Each | Pkg. Qty. | Pkg. | |||

Aluminum | ||||||||||||||||||||

With Ribbed Steps | ||||||||||||||||||||

| 4 | 1 | 350 | 12" | 18" | 18" | 12" | 16" | 14" | __ | Assembled | Four Swivel Casters | Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910 Subpart D, ANSI/ASSE A1264.1 | 0000000 | 0000000 | __ | 000000 | 00 | 4 | 0000000 | 00000 |

| 4 | 2 | 350 | 20" | 18" | 23" | 20" | 16" | 14" | 4" | Assembled | Four Swivel Casters | Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 0000000 | 000000 | 1 | 00000000 | 000000 | __ | 000000 | 00 |

| 4 | 3 | 350 | 30" | 22" | 29" | 30" | 16" | 14" | 4 1/2" | Assembled | Four Swivel Casters | Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 0000000 | 000000 | 1 | 00000000 | 00000 | __ | 000000 | 00 |

| 4 | 4 | 350 | 40" | 22" | 36" | 40" | 16" | 14" | 4 1/2" | Assembled | Four Swivel Casters | OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 0000000 | 000000 | 1 | 00000000 | 00000 | __ | 000000 | 00 |

With Serrated Steps | ||||||||||||||||||||

| 3 | 2 | 350 | 20" | 18" | 23" | 20" | 16" | 14" | 4" | Assembled | Four Swivel Casters | Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 0000000 | 000000 | 1 | 00000000 | 00000 | __ | 000000 | 00 |

| 3 | 3 | 350 | 30" | 22" | 29" | 30" | 16" | 14" | 4 1/2" | Assembled | Four Swivel Casters | Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 0000000 | 000000 | 1 | 00000000 | 00000 | __ | 000000 | 00 |

| 3 | 4 | 350 | 40" | 22" | 36" | 40" | 16" | 14" | 4 1/2" | Assembled | Four Swivel Casters | OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 0000000 | 000000 | 1 | 00000000 | 00000 | __ | 000000 | 00 |

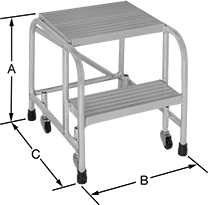

Rolling Step Stools with Handrail

Grip the handrail for stability. Casters are spring loaded—when you're on the stool, they retract to keep the stool stationary. When you step off, the casters roll again.

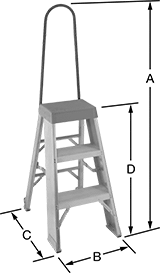

Overall | Top Step | Bottom Step | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., lbs. | Ht.(A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Wheel Configuration | Specifications Met | Each | |

Aluminum | |||||||||||||

With Serrated Steps | |||||||||||||

| 500 | 50" | 28" | 46" | 20" | 24" | 24" | 24" | 10 1/2" | Unassembled | Four Swivel Casters | OSHA Compliant 29 CFR 1910 Subpart D, ANSI/ASSE A1264.1 | 000000 | 0000000 |

| 500 | 50" | 28" | 62" | 20" | 24" | 39 1/2" | 24" | 10 1/2" | Unassembled | Four Swivel Casters | OSHA Compliant 29 CFR 1910 Subpart D, ANSI/ASSE A1264.1 | 000000 | 000000 |

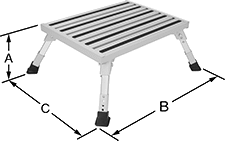

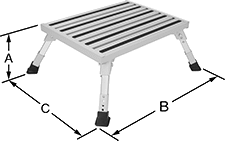

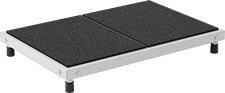

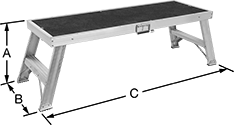

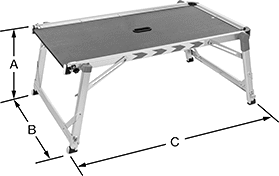

Lightweight Antifatigue Work Platforms

Made of aluminum, these work platforms are lighter in weight than steel platforms, so they’re easier to move from job to job. They’re lined with soft vinyl foam to ease the strain of standing for long periods. Turn the legs to raise or lower the height of the platform.

Note: Work platforms meet OSHA and Cal/OSHA dimensional and construction standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe setup and operating practices.

For technical drawings and 3-D models, click on a part number.

Platforms | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Top Step | Mat | Replacement Rubber Nonskid Feet | ||||||||||||

| Wd. | Dp. | Wd. | Dp. | Cap., lbs. | Wt., lbs. | Material | Color | Assembled or Unassembled | Features | Specifications Met | Each | Pkg. Qty. | Pkg. | ||

Gray Aluminum | |||||||||||||||

5"-8" Overall Ht. | |||||||||||||||

| 24" | 19" | 24" | 19" | 800 | 17 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 0000000 | 4 | 00000000 | 000000 |

| 24" | 24" | 24" | 24" | 800 | 18 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 36" | 19" | 36" | 19" | 800 | 21 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 36" | 24" | 36" | 24" | 800 | 23 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 47" | 19" | 47" | 19" | 800 | 24 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 47" | 24" | 47" | 24" | 800 | 27 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 72" | 24" | 72" | 24" | 800 | 41 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

9"-14" Overall Ht. | |||||||||||||||

| 24" | 19" | 24" | 19" | 800 | 19 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 24" | 24" | 24" | 24" | 800 | 21 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 36" | 19" | 36" | 19" | 800 | 23 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 36" | 24" | 36" | 24" | 800 | 25 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 47" | 19" | 47" | 19" | 800 | 26 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 47" | 24" | 47" | 24" | 800 | 29 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000 | 4 | 00000000 | 00000 |

| 72" | 24" | 72" | 24" | 800 | 45 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 00000000 | 4 | 00000000 | 00000 |

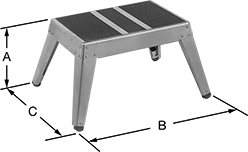

Folding Work Platforms

Folding legs make these platforms easy to take anywhere. When folded, legs lock in place under the platform with safety clips. Climb up from either side. These platforms offer good slip resistance.

Platforms with an aluminum top step are lightweight and have legs that individually adjust to your ideal working height.

Platforms with a plywood top step have a higher weight capacity than those with an aluminum top step.

Top Step | Overall | Bottom Step | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Dp. | Material | Ht. (A) | Wd. (B) | Dp. (C) | Wd. | Dp. | Step Material | Cap., lbs. | Wt., lbs. | Assembled or Unassembled | Features | Each | |

Aluminum | ||||||||||||||

| 11 3/4" | 30 3/4" | Ribbed Aluminum | 23 3/4"-35" | 22 1/4" | 51"-60" | 12 1/2" | 5 1/4" | Aluminum | 300 | 15 | Assembled | Adjustable-Height Legs, Nonskid Feet | 000000000 | 0000000 |

| 22 3/4" | 60 1/4" | Grit-Coated Plywood | 21" | 22 1/2" | 69" | 21" | 2 1/8" | Aluminum | 500 | 37 | Assembled | Carrying Handle | 00000000 | 000000 |

Uneven Surface Folding Work Platforms

Create a level and stable place to stand when working on stairs, ramps, and curbs. Each leg on these platforms is adjustable, so you can set them at the exact heights you need to compensate for uneven surfaces. To ensure the legs don’t collapse during use, the leg locks require two hands to disengage. Rubber nonskid feet prevent the legs from shifting on uneven ground. On top of these platforms, a grit-coated surface gives your boots reliable traction. Two side supports extend to brace against the top of a step for added stability on stairs. Fold these platforms and carry them by the handle for easy transport.

Note: Check local, state, and federal codes, including OSHA, for safe setup and operating practices.

Top Step | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Dp. | Material | Ht. (A) | Wd. (B) | Dp. (C) | Cap., lbs. | Wt., lbs. | Assembled or Unassembled | Each | |

Aluminum | ||||||||||

| 22 1/2" | 43" | Grit-Coated Plywood | 18"-30" | 29 1/2" | 45 1/2"-50 1/2" | 350 | 28 | Assembled | 00000000 | 0000000 |

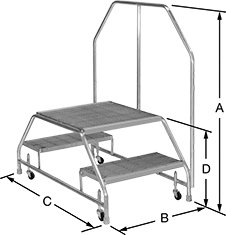

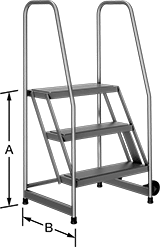

Mobile Stairs

|  Ribbed |

Serrated |

Tilt these stairs sideways to roll them between work areas. When you stand them upright, the wheels lift off the floor, so these stairs won’t move while they’re in use. The top step sits flush against walls or work platforms to add stability. All have nonskid feet.

Aluminum stairs resist corrosion in damp areas. They’re lighter in weight than steel stairs, so they’re easier to move around your facility.

Vinyl-coated and ribbed steps are slip-resistant and easy on your feet.

Perforated and serrated steps have openings so liquids can drain and debris can fall through. Serrated steps are more slip resistant than perforated steps, but they’re less comfortable when you’re standing for long periods.

Note: Stairs meet OSHA and Cal/OSHA dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe setup and operating practices.

For technical drawings and 3-D models, click on a part number.

Overall | Step | Handrail | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Landing Ht. (A) | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Wd. | Dp. | Cap., lbs. | Ht. | Color | Wheel Configuration | Assembled or Unassembled | Specifications Met | Each | |

Aluminum | ||||||||||||||

Ribbed Steps | ||||||||||||||

| 1'8" | 31 1/2" | 19" | 60° | 2 | 24" | 9 1/2" | 450 | 30" | Gray | Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3627 | 00000000 | 0000000 |

| 2'6" | 31 1/2" | 22" | 60° | 3 | 24" | 9 1/2" | 450 | 30" | Gray | Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3627 | 00000000 | 000000 |

| 3'4" | 31 1/2" | 28" | 60° | 4 | 24" | 9 1/2" | 450 | 30" | Gray | Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3627 | 00000000 | 000000 |

Serrated Steps | ||||||||||||||

| 1'8" | 31 1/2" | 19" | 60° | 2 | 24" | 9 1/2" | 450 | 30" | Gray | Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3627 | 00000000 | 000000 |

| 2'6" | 31 1/2" | 22" | 60° | 3 | 24" | 9 1/2" | 450 | 30" | Gray | Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3627 | 00000000 | 000000 |

| 3'4" | 31 1/2" | 28" | 60° | 4 | 24" | 9 1/2" | 450 | 30" | Gray | Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3627 | 00000000 | 000000 |