Step Stools

Get a secure and stable step up.

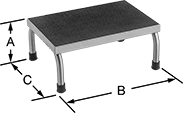

304 stainless steel stools stand up to repeated washdowns and resist damage from grease and chemicals.

Perforated, coated, and ribbed steps provide good slip resistance while being easy on your shoes. Note: Stools that have OSHA or Cal/OSHA specifications listed meet dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Overall | Top Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Features | Specifications Met | Each | |

304 Stainless Steel | |||||||||||||||

With Vinyl-Coated Steps | |||||||||||||||

| 7 | 1 | 375 | 8" | 14 1/2" | 11 1/2" | 7" | 14" | 10" | __ | __ | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 0000000 |

| 7 | 1 | 375 | 8" | 18" | 14" | 7" | 18" | 12" | __ | __ | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

| 7 | 1 | 375 | 8" | 31" | 14" | 7" | 30" | 12" | __ | __ | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

| 7 | 2 | 300 | 16" | 18" | 25" | 15" | 18" | 11 1/2" | 18" | 11 1/2" | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

| Replacement Rubber Nonskid Feet for Style 7 Step Stools (Pkg. of 4) | 0000000 | Pkg. | 000000 |

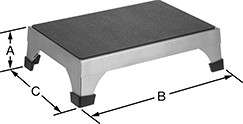

Stackable Step Stools

Stack these stools on top of each other to reach your ideal height. They lock together to create a stable platform while you work. Made of 304 stainless steel, they withstand repeated washdowns and won’t corrode in wet environments. Rubber-coated steps prevent slipping and are easy on your shoes.

Note: Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Overall | Top Step | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Assembled or Unassembled | Specifications Met | Each | |

304 Stainless Steel | |||||||||||

With Rubber-Coated Steps | |||||||||||

| 1 | 400 | 5" | 18" | 12" | 5" | 18" | 12" | Assembled | OSHA Compliant 29 CFR 1910.23 | 00000000 | 0000000 |

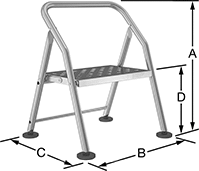

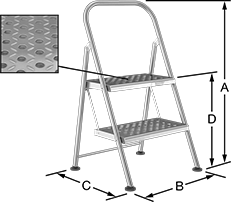

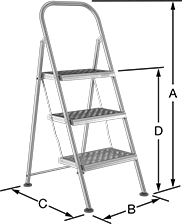

Folding Clean Room Step Stools

Fold these step stools for easy transport and storage. They meet Fed. Std. Class 100 and ISO Class 5 clean room requirements. Stools are 316 stainless steel to withstand repeated washdowns. They have a smooth finish and seamless welds, so there are no cracks or crevices that can harbor dust, dirt, and bacteria. Steps are perforated for slip resistance that’s easy on your shoes. Adjust the nonmarring leveling feet to compensate for uneven floors.

Overall | Top Step | Middle Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht.(A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Environmental Rating | Specifications Met | Each | |

316 Stainless Steel | ||||||||||||||||

With Perforated Steps | ||||||||||||||||

| 1 | 250 | 22" | 17" | 16" | 11" | 15" | 10" | __ | __ | 15" | 10" | Assembled | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 000000000 |

| 2 | 250 | 36" | 20" | 20" | 19" | 15" | 10" | __ | __ | 16" | 10" | Assembled | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 00000000 |

| 3 | 250 | 45" | 18" | 26" | 29" | 15" | 10" | 16" | 10" | 16" | 10" | Assembled | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 00000000 |

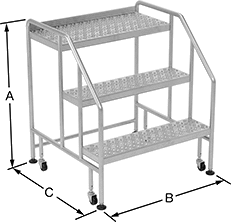

Rolling Clean Room Step Stools

With spring-loaded casters, these step stools are easy to move between work areas in your clean room. When you're on the stool, the casters retract to keep the stool stationary; when you step off, the casters roll again. Stools meet Fed. Std. Class 100 and ISO Class 5 clean room requirements. Made of 316 stainless steel, they withstand repeated washdowns. Steps are perforated for slip resistance that’s easy on your shoes. The leveling feet and wheels are nonmarring.

Overall | Top Step | Middle Step | Bottom Step | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Wheel Configuration | Environmental Rating | Specifications Met | Each | |

316 Stainless Steel | |||||||||||||||||

With Perforated Steps | |||||||||||||||||

| 2 | 300 | 25" | 30" | 21 1/2" | 21" | 28" | 13" | __ | __ | 28" | 7 1/2" | Assembled | Four Swivel Casters | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 000000000 |

| 3 | 300 | 34" | 30" | 29" | 31" | 28" | 13" | 28" | 7 1/2" | 28" | 7 1/2" | Assembled | Four Swivel Casters | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 00000000 |

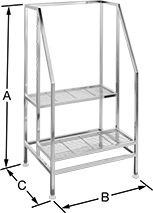

Clean Room Step Stools with Handrail

Designed for use in clean rooms, these step stools with a handrail are also used in other sanitary environments such as food-processing and pharmaceutical plants. Made of 304 stainless steel, they hold up to strong cleaners and sanitizers without corroding. Water flows easily through their bar grating steps when you wash them down. To account for uneven floors, adjust their nonskid leveling feet; these feet are nonmarring.

Electropolished stools are polished smooth to leave no crevices for bacteria growth and make cleaning easier.

Overall | Top Step | Bottom Step | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Steps | Capacity, lbs. | Height (A) | Width (B) | Depth (C) | Height | Width | Depth | Width | Depth | Assembled or Unassembled | Environmental Rating | Each | |

304 Stainless Steel | |||||||||||||

With Bar Grating Steps | |||||||||||||

| 2 | 250 | 54" | 30" | 24" | 24" | 30" | 12 1/2" | 30" | 12 1/2" | Assembled | Fed. Std. Class 1,000 | 00000000 | 000000000 |

Electropolished 304 Stainless Steel | |||||||||||||

With Bar Grating Steps | |||||||||||||

| 2 | 250 | 54" | 30" | 24" | 24" | 30" | 12 1/2" | 30" | 12 1/2" | Assembled | Fed. Std. Class 100 | 00000000 | 00000000 |

Corrosion-Resistant Antifatigue Work Platforms

Designed for workstations that are frequently washed down, such as those in food processing plants, these platforms ease the strain of standing for long periods. They’re made from 304 stainless steel, so they resist corrosion in wet areas. The top is lined with soft vinyl foam to cushion your feet. Turn the legs to raise or lower the height of the platform.

Note: Work platforms meet OSHA and Cal/OSHA dimensional and construction standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe setup and operating practices.

Platforms | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Top Step | Mat | Replacement Rubber Nonskid Feet | |||||||||||

| Wd. | Dp. | Wd. | Dp. | Cap., lbs. | Wt., lbs. | Material | Color | Assembled or Unassembled | Features | Specifications Met | Each | Pkg. | ||

304 Stainless Steel | ||||||||||||||

5"-8" Overall Ht. | ||||||||||||||

| 24" | 19" | 24" | 19" | 800 | 24 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 0000000 | 00000000 | 000000 |

| 24" | 24" | 24" | 24" | 800 | 28 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 19" | 36" | 19" | 800 | 34 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 24" | 36" | 24" | 800 | 39 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

9"-14" Overall Ht. | ||||||||||||||

| 24" | 19" | 24" | 19" | 800 | 27 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 24" | 24" | 24" | 24" | 800 | 31 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 19" | 36" | 19" | 800 | 36 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 24" | 36" | 24" | 800 | 41 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

Corrosion-Resistant Work Platforms

Made of 304 stainless steel, these platforms withstand wet environments and repeated washdowns without corroding. A serrated platform prevents slipping and allows liquids and debris to pass through. However, it can be uncomfortable to stand on for long periods. Turn the legs to raise or lower the platform to your desired working height.

Note: Work platforms meet OSHA and Cal/OSHA dimensional and construction standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe setup and operation practices.

Platforms | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Top Step | Replacement Rubber Nonskid Feet | ||||||||||||

| Wd. | Dp. | Wd. | Dp. | Step Tread | Cap., lbs. | Wt., lbs. | Color | Assembled or Unassembled | Features | Specifications Met | Each | Each | ||

304 Stainless Steel | ||||||||||||||

7"-9" Overall Ht. | ||||||||||||||

| 24" | 19" | 24" | 19" | Serrated | 500 | 33 | Gray | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622 | 0000000 | 0000000 | 0000000 | 00000 |

| 35" | 24" | 35" | 24" | Serrated | 500 | 42 | Gray | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622 | 0000000 | 00000000 | 0000000 | 0000 |

11"-17" Overall Ht. | ||||||||||||||

| 24" | 19" | 24" | 19" | Serrated | 500 | 39 | Gray | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622 | 0000000 | 00000000 | 0000000 | 0000 |

| 35" | 24" | 35" | 24" | Serrated | 500 | 47 | Gray | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622 | 0000000 | 00000000 | 0000000 | 0000 |