Step Stools

Get a secure and stable step up.

Aluminum and plastic stools are lighter than steel or fiberglass stools, which makes them easy to move between work areas. Perforated, coated, and ribbed steps provide good slip resistance while being easy on your shoes. Note: Stools that have OSHA or Cal/OSHA specifications listed meet dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

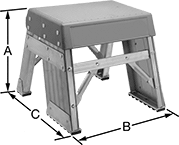

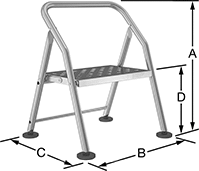

Overall | Top Step | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Assembled or Unassembled | Features | Specifications Met | Each | |

Aluminum | |||||||||||||

With Ribbed Steps | |||||||||||||

| 4 | 1 | 375 | 13" | 15" | 16" | 13" | 14" | 9 1/4" | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1926.1053 | 00000000 | 0000000 |

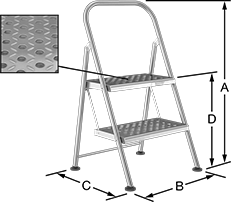

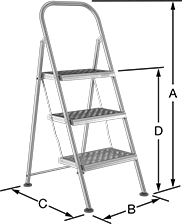

Folding Step Stools

Fold for easy transport and storage.

Aluminum stools are lighter weight than steel and fiberglass, making them easier to move between work areas. Fiberglass stools are nonconductive for use in electrical work.

Style 3 stools are ideal for office spaces and light duty applications.

Style 4 stools have additional bracing for higher capacities than Style 3, so they’re a more common choice for industrial applications.

Style 6 stools can be used in pairs to create a work surface or scaffold. They have a braced top step that is designed to hold a plank or platform between the pair of stools.

Stools with ribbed steps have good slip resistance and are gentle on your footwear.

Type II stools are tested to hold up to 225 lbs. Type 1A stools are tested to hold up to 300 lbs. Type 1AA stools are tested to hold up to 375 lbs.

Note: Step stools that meet OSHA or Cal/OSHA specifications adhere to dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

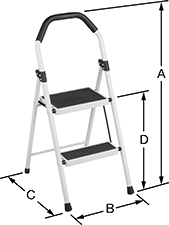

Overall | Top Step | Middle Step | Bottom Step | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Color | Specifications Met | Each | |

Steel | |||||||||||||||||

With Ribbed Steps | |||||||||||||||||

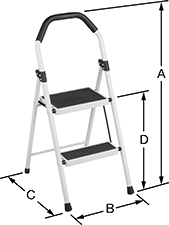

| 2 | 225 | Type II | 34" | 16" | 19" | 18" | 12" | 8" | __ | __ | 12" | 4" | Assembled | White | OSHA Compliant 29 CFR 1926.1053 ANSI A14.11 | 0000000 | 000000 |

| 3 | 225 | Type II | 43" | 17" | 26" | 27" | 12" | 8" | 12" | 4" | 12" | 4" | Assembled | White | OSHA Compliant 29 CFR 1926.1053 ANSI A14.11 | 0000000 | 00000 |

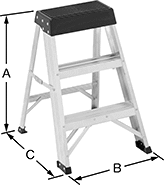

Overall | Top Step | Middle Step | Bottom Step | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Color | Specifications Met | Each | |

Aluminum | |||||||||||||||||

With Ribbed Steps | |||||||||||||||||

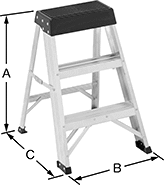

| 2 | 375 | Type 1AA | 23" | 18" | 21" | 23" | 14" | 9 1/4" | __ | __ | 17 1/4" | 6" | Assembled | __ | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 00000000 | 0000000 |

| 3 | 300 | Type 1A | 24" | 17" | 19" | 24" | 12" | 6" | 12" | 3" | 13 1/2" | 3" | Assembled | __ | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 0000000 | 00000 |

| 3 | 375 | Type 1AA | 33" | 20" | 27" | 33" | 14" | 9 1/4" | 19 3/4" | 6" | 19 3/4" | 6" | Assembled | __ | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 00000000 | 000000 |

Fiberglass | |||||||||||||||||

With Ribbed Steps | |||||||||||||||||

| 2 | 375 | Type 1AA | 23" | 18" | 21" | 23" | 14" | 9 1/4" | __ | __ | 17 1/4" | 6" | Assembled | Orange | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 000000000 | 000000 |

| 3 | 300 | Type 1A | 24" | 18" | 20" | 24" | 12" | 5 1/2" | 11" | 3" | 12 1/2" | 3" | Assembled | Orange | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.5 | 0000000 | 000000 |

| 3 | 375 | Type 1AA | 33" | 20" | 27" | 33" | 14" | 9 1/4" | 19 3/4" | 6" | 19 3/4" | 6" | Assembled | Orange | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.2 | 000000000 | 000000 |

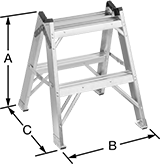

Overall | Top Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Color | Specifications Met | Each | |

Aluminum | |||||||||||||||

With Ribbed Steps | |||||||||||||||

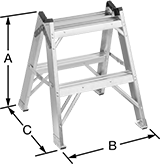

| 2 | 300 | Type 1A | 24" | 21" | 23 1/2" | 23" | 14" | 8 1/4" | 14" | 3" | Assembled | __ | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.11 | 0000000 | 0000000 |

Fiberglass | |||||||||||||||

With Ribbed Steps | |||||||||||||||

| 2 | 300 | Type 1A | 24" | 21" | 23" | 23" | 14" | 8 1/4" | 14" | 3" | Assembled | Orange | Cal/OSHA Compliant Title 8 Section 3276 OSHA Compliant 29 CFR 1926.1053 ANSI A14.11 | 0000000 | 000000 |

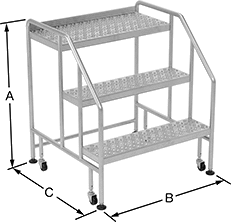

Folding Step Stools with Handrail

Grab the handrail for stability. These stools fold for easy transport and storage.

Aluminum stools are lighter than steel and fiberglass, making them easier to move between work areas. Fiberglass stools are nonconductive for use in electrical work.

Perforated, coated, and ribbed steps provide good slip resistance and are gentle on your footwear.Stools with casters can be moved by tilting them. They remain stationary when upright.

Note: Step stools that meet OSHA or Cal/OSHA specifications adhere to dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating procedures.

Overall | Top Step | Bottom Step | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Steps | Cap., lbs. | Duty Rating | Ht. (A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. | Dp. | Wd. | Dp. | Wheel Configuration | Color | Specifications Met | Includes | Each | |

Aluminum | |||||||||||||||||

With Rubber-Coated Steps | |||||||||||||||||

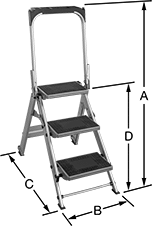

| 2 | 2 | 300 | Type 1A | 34" | 21" | 22" | 18" | 14" | 9" | 14" | 9" | Two Rigid Casters | __ | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.2 | __ | 0000000 | 0000000 |

| 2 | 3 | 300 | Type 1A | 51" | 22" | 33" | 26" | 14" | 9" | 14" | 9" | Two Rigid Casters | __ | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.2 | Handrail-Mounted Tool Tray | 0000000 | 000000 |

| 2 | 4 | 300 | Type 1A | 59" | 22" | 46" | 35" | 14" | 9" | 14" | 9" | Two Rigid Casters | __ | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.2 | Handrail-Mounted Tool Tray | 0000000 | 000000 |

Fiberglass | |||||||||||||||||

With Ribbed Steps | |||||||||||||||||

| 2 | 3 | 375 | Type 1AA | 42" | 21" | 33" | 26" | 13 3/4" | 8 1/2" | 14" | 9" | __ | Green | Cal/OSHA Compliant Title 8 Section 3276, OSHA Compliant 29 CFR 1910.23, OSHA Compliant 29 CFR 1926.1053, ANSI A14.5 | Handrail-Mounted Tool Tray | 000000000 | 000000 |

Folding Clean Room Step Stools

Fold these step stools for easy transport and storage. They meet Fed. Std. Class 100 and ISO Class 5 clean room requirements. Stools are 316 stainless steel to withstand repeated washdowns. They have a smooth finish and seamless welds, so there are no cracks or crevices that can harbor dust, dirt, and bacteria. Steps are perforated for slip resistance that’s easy on your shoes. Adjust the nonmarring leveling feet to compensate for uneven floors.

Overall | Top Step | Middle Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht.(A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Environmental Rating | Specifications Met | Each | |

316 Stainless Steel | ||||||||||||||||

With Perforated Steps | ||||||||||||||||

| 1 | 250 | 22" | 17" | 16" | 11" | 15" | 10" | __ | __ | 15" | 10" | Assembled | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 000000000 |

| 2 | 250 | 36" | 20" | 20" | 19" | 15" | 10" | __ | __ | 16" | 10" | Assembled | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 00000000 |

| 3 | 250 | 45" | 18" | 26" | 29" | 15" | 10" | 16" | 10" | 16" | 10" | Assembled | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 00000000 |

Rolling Clean Room Step Stools

With spring-loaded casters, these step stools are easy to move between work areas in your clean room. When you're on the stool, the casters retract to keep the stool stationary; when you step off, the casters roll again. Stools meet Fed. Std. Class 100 and ISO Class 5 clean room requirements. Made of 316 stainless steel, they withstand repeated washdowns. Steps are perforated for slip resistance that’s easy on your shoes. The leveling feet and wheels are nonmarring.

Overall | Top Step | Middle Step | Bottom Step | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Wheel Configuration | Environmental Rating | Specifications Met | Each | |

316 Stainless Steel | |||||||||||||||||

With Perforated Steps | |||||||||||||||||

| 2 | 300 | 25" | 30" | 21 1/2" | 21" | 28" | 13" | __ | __ | 28" | 7 1/2" | Assembled | Four Swivel Casters | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 000000000 |

| 3 | 300 | 34" | 30" | 29" | 31" | 28" | 13" | 28" | 7 1/2" | 28" | 7 1/2" | Assembled | Four Swivel Casters | Fed. Std. Class 100, ISO Class 5 | OSHA Compliant 29 CFR 1926.1053 | 0000000 | 00000000 |