Filter by

Body Shape

Maximum Holding Torque

Shaft Diameter

Shaft Length

Face Shape

Overall Width

Mounting Position

Full Step Increment

Overall Height

Motor Frame Size

Thrust Load Capacity

Direction of Operation

Number of Shafts

Enclosure Material

Wire Connection

Component

Motor Type

Export Control Classification Number (ECCN)

REACH

RoHS

DFARS Specialty Metals

Hollow-Shaft Stepper Motors

Motors

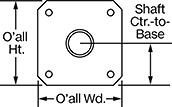

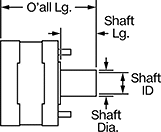

Overall | Shaft | Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Holding Torque, in·ozf | Max. Rotation Speed, rpm | Max. Current per Phase, amp | Full Step Increment | Stepper Motor Polarity | No. of Wire Leads | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Type | ID | No. of Shafts | Min. | Max. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEMA 17 Frame Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16.9 | 1,475 | 1.2 | 0.9° | Bipolar | 4 | 1.9" | 1.7" | 1.7" | 1/2" | 3/4" | 0.84" | Hollow | 7/16" | 1 | 0 | 120 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33.9 | 1,700 | 1.4 | 0.9° | Bipolar | 4 | 2.5" | 1.7" | 1.7" | 1/2" | 3/4" | 0.84" | Hollow | 7/16" | 1 | 0 | 120 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||