Filter by

Overall Height

Material

Rail Height

Color

T-Slotted Framing Component

Finish

Mount Type

Bracket Type

DFARS Specialty Metals

Overall Weight Capacity

Mobility

Shelf Material

Most Likely Products

All Results

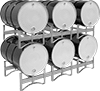

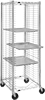

Containers, Storage, and Furniture

Building and Machinery Hardware

Material Handling

Facility and Grounds Maintenance

Safety Equipment

Measuring and Inspecting

Fastening and Joining