Selecting Clamps Using Pipe, Conduit, or Tubing Trade Size

More

Strut Channel Feet

Provide a stable, nonmarring base for strut channel legs.

| For Strut Channel Ht. | For Strut Channel Wd. | Dia. | Thick. | Material | Color | Insert Material | Capacity, lbs. | Each | |

| 1 5/8" | 1 5/8" | 3" | 1/2" | Rubber | Black | Steel | 200 | 000000 | 00000 |

Strut Channel End Stops

Block strut channel ends to keep trolleys, slides, and other hanging components from rolling out.

For Strut Channel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | No. of Holes | Hole Dia. | Color | Material | Fasteners Included | Each | |

| 1 5/8", 2 7/16", 3 1/4" | 1 5/8" | 1 | 9/16" | Black | Rubber | Yes | 0000000 | 000000 |

Strut Channel Covers

Create a four-sided raceway for cable, or give a more finished look to strut channel structures.

Rubber covers cushion pipe and duct work to reduce vibration. They’re also flexible.

10 ft. | |||

|---|---|---|---|

| Material | For Strut Channel Wd. | Each | |

Flexible | |||

| Black Rubber | 1 5/8" | 00000000 | 0000000 |

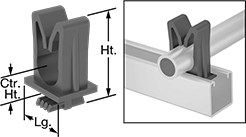

Strut-Mount Vibration-Damping Routing Clamps

Slide multiple clamps into existing strut channel to organize lines of pipe, tubing, and conduit without the need for drilling, welding, or using adhesive. Clamps have a plastic or rubber cushion or body to reduce vibration.

TPE clamps hold lines of pipe, tubing, and conduit in light duty applications without the need for fasteners or installation tools. Made from a single piece of rubber, they prevent corrosion caused by metal-to-metal contact and resist most oils, chemicals, and cleaning compounds. To install, insert the clamp into strut channel and twist it 90° to secure. Then, press material into the clamp.

ID | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | Metric, mm | For Pipe Size | Capacity | Lg. | Wd. | Ht. | Center Ht. | Thick. | For Strut Channel Wd. | Temp. Range, °F | Each | |

TPE Rubber | ||||||||||||

| 1/4" | 6 | __ | 75 lbs. | 1 5/16" | 1 3/8" | 1 5/16" | 3/16" | 5/64" | 1 5/8" | -50° to 275° | 000000000 | 00000 |

| 3/8" | 10 | __ | 75 lbs. | 1 5/16" | 1 3/8" | 1 1/2" | 5/16" | 5/64" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 1/2" | 13 | 1/8 | 75 lbs. | 1 1/2" | 1 3/8" | 1 13/16" | 7/16" | 3/32" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 5/8" | 16 | 1/4 | 75 lbs. | 1 1/2" | 1 3/8" | 2" | 1/2" | 7/64" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 3/4" | 18 | __ | 75 lbs. | 1 1/2" | 1 3/8" | 2 1/8" | 1/2" | 1/8" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 3/4" | 19 | 3/8 | 75 lbs. | 1 1/2" | 1 3/8" | 2 1/8" | 9/16" | 9/64" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 7/8" | 22 | 1/2 | 75 lbs. | 1 5/8" | 1 3/8" | 2 1/2" | 11/16" | 5/32" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 15/16" | 23 | __ | 75 lbs. | 1 5/8" | 1 3/8" | 2 1/2" | 11/16" | 5/32" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 1 1/8" | 29 | 3/4 | 75 lbs. | 1 15/16" | 1 3/8" | 2 7/8" | 13/16" | 3/16" | 1 5/8" | -50° to 275° | 000000000 | 0000 |

| 1 3/16" | 30 | __ | 75 lbs. | 1 15/16" | 1 3/8" | 3" | 13/16" | 3/16" | 1 5/8" | -50° to 275° | 000000000 | 0000 |