Filter by

Application

Material

Clevis Inside Width

Weight Capacity

Length

Clevis Inside Length

System of Measurement

Export Control Classification Number (ECCN)

DFARS Specialty Metals

RoHS

Specifications Met

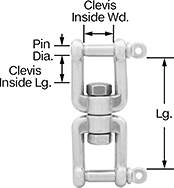

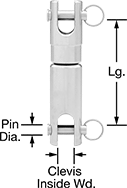

Clevis-to-Clevis Swivels—Not for Lifting

|

For easy positioning before a load is applied, these rotate to minimize twisting and knotting of rope and chain.

Hot-Dipped Galvanized Steel—Hot-dipped galvanized steel swivels have a thick coating for corrosion resistance.

316 Stainless Steel—316 stainless steel swivels have excellent resistance to salt water and chemicals. They’re more corrosion resistant than hot-dipped galvanized steel swivels.

Clevis | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Inside Wd. | Inside Lg. | Pin Dia. | Wt. Cap., lb. | Fabrication | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot-Dipped Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3/8" | 3/8" | 3/16" | 450 | Forged | 37405T32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 1/2" | 1/2" | 1/4" | 750 | Forged | 37405T33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 11/16" | 11/16" | 11/16" | 5/16" | 1,200 | Forged | 37405T34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 3/4" | 1" | 3/8" | 2,000 | Forged | 37405T35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/32" | 1" | 1 1/4" | 1/2" | 3,500 | Forged | 37405T36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 11/32" | 1 1/4" | 1 1/2" | 5/8" | 5,000 | Forged | 37405T37 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/2" | 1 5/8" | 1 3/4" | 3/4" | 7,000 | Forged | 37405T38 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 7/16" | 3/8" | 3/16" | 300 | Cast | 37405T31 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 1/2" | 7/16" | 1/4" | 600 | Cast | 37405T24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 17/32" | 5/8" | 5/8" | 5/16" | 1,100 | Cast | 37405T25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/16" | 3/4" | 13/16" | 3/8" | 1,500 | Cast | 37405T26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 5/16" | 1" | 15/16" | 1/2" | 2,600 | Cast | 37405T27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 7/16" | 1 1/4" | 1 3/8" | 5/8" | 4,700 | Cast | 37405T28 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 7/32" | 1 1/2" | 1 1/2" | 3/4" | 7,100 | Cast | 37405T29 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

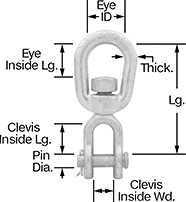

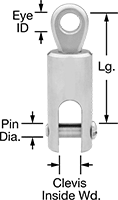

Eye-to-Clevis Swivels—Not for Lifting

|

These rotate for easy positioning before a load is applied to minimize twisting and knotting of rope and chain.

Galvanized Steel—Galvanized steel swivels have a thick coating for corrosion resistance.

316 Stainless Steel—316 stainless steel swivels have excellent resistance to salt water and chemicals. They’re more corrosion resistant than hot-dipped galvanized steel swivels.

Eye | Clevis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | Inside Lg. | ID | Inside Wd. | Inside Lg. | Pin Dia. | Pin Type | Wt. Cap., lb. | Fabrication | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 5/16" | 3/4" | 1" | 1/2" | 13/16" | 5/16" | Cotter | 1,200 | Forged | Fed. Spec. RR-C-271 | 3553T15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 3/8" | 7/8" | 1 1/4" | 5/8" | 1 1/16" | 3/8" | Cotter | 2,200 | Forged | Fed. Spec. RR-C-271 | 3553T16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 9/16" | 1/2" | 1 1/4" | 1 1/2" | 7/8" | 1 7/16" | 1/2" | Cotter | 3,600 | Forged | Fed. Spec. RR-C-271 | 3553T17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2" | 5/8" | 1 9/16" | 1 3/4" | 1" | 1 1/2" | 5/8" | Cotter | 5,200 | Forged | Fed. Spec. RR-C-271 | 3553T18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1 3/4" | 2" | 1 1/8" | 1 3/4" | 3/4" | Cotter | 7,000 | Forged | Fed. Spec. RR-C-271 | 3553T19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1/4" | 9/16" | 5/8" | 1/2" | 7/16" | 7/32" | Screw | 600 | Cast | — | 30365T31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 11/16" | 5/16" | 13/16" | 13/16" | 23/32" | 5/8" | 5/16" | Screw | 1,000 | Cast | — | 30365T32 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 5/8" | 3/8" | 1 1/16" | 15/16" | 13/16" | 15/16" | 3/8" | Screw | 1,900 | Cast | — | 30365T33 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 5/8" | 1/2" | 1 3/8" | 1 3/16" | 15/16" | 1 1/8" | 1/2" | Screw | 2,700 | Cast | — | 30365T34 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | 5/8" | 1 3/4" | 1 1/2" | 1 1/4" | 1 1/2" | 5/8" | Screw | 4,600 | Cast | — | 30365T35 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 13/16" | 3/4" | 2" | 1 5/8" | 1 23/32" | 1 11/16" | 25/32" | Screw | 5,500 | Cast | — | 30365T36 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

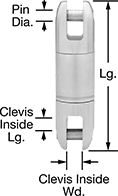

Clevis-to-Clevis Ball Bearing Swivels—For Lifting

|

You can use these in critical applications to adjust the position of a fitting or an object under load and minimize twisting and knotting. The bearings are permanently lubricated and sealed to keep out debris.

Note: Swivels are for vertical lifting only.

316 Stainless Steel—316 stainless steel swivels have excellent resistance to salt water and chemicals.

Clevis | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Inside Wd. | Inside Lg. | Pin Dia. | Wt. Cap., lb. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 11/32" | 5/16" | 15/32" | 5/16" | 1,000 | ASME B30.26 | 33575T651 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 19/32" | 11/16" | 3/8" | 1,500 | ASME B30.26 | 33575T652 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 9/16" | 19/32" | 13/16" | 7/16" | 3,000 | ASME B30.26 | 33575T653 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 5/32" | 3/4" | 15/16" | 5/8" | 6,000 | ASME B30.26 | 33575T654 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 1/2" | 1" | 1 9/16" | 7/8" | 10,000 | ASME B30.26 | 33575T655 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 19/32" | 11/16" | 3/8" | 1,500 | ASME B30.26 | 33575T501 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 29/32" | 19/32" | 13/16" | 7/16" | 3,000 | ASME B30.26 | 33575T502 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/2" | 3/4" | 15/16" | 5/8" | 6,000 | ASME B30.26 | 33575T503 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 1" | 1 9/16" | 7/8" | 10,000 | ASME B30.26 | 33575T504 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

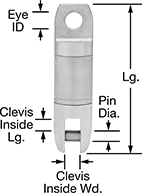

Eye-to-Clevis Ball Bearing Swivels—For Lifting

|

Adjust the position of a fitting or an object under load and minimize twisting and knotting in critical applications. The bearings are permanently lubricated and sealed to keep out debris.

Note: Swivels are for vertical lifting only.

Eye | Clevis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | ID | Inside Wd. | Inside Lg. | Pin Dia. | Wt. Cap., lb. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 1/4" | 1/4" | 5/16" | 5/16" | 5/16" | 1,000 | ASME B30.26 | 33575T1 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 9/16" | 5/16" | 3/8" | 3/8" | 1/2" | 3/8" | 1,500 | ASME B30.26 | 33575T2 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 9/16" | 1/2" | 5/8" | 7/16" | 23/32" | 7/16" | 3,000 | ASME B30.26 | 33575T3 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/8" | 3/4" | 7/8" | 3/4" | 15/16" | 5/8" | 6,000 | ASME B30.26 | 33575T4 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 1/2" | 1" | 1 1/4" | 1" | 1 1/8" | 7/8" | 10,000 | ASME B30.26 | 33575T5 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Eye-to-Clevis Ball Bearing Swivels—Not for Lifting

|

Use these to adjust the position of a fitting or an object under load and minimize twisting and knotting. The bearings are permanently lubricated and sealed to keep out debris. They have excellent resistance to salt water and chemicals.

Eye | Clevis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | ID | Inside Wd. | Pin Dia. | Wt. Cap., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 1/4" | 5/16" | 3/8" | 1/4" | 1,800 | 8928T33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clevis-to-Clevis Ball Bearing Swivels—Not for Lifting

|

Minimize twisting and knotting of rope and chain and adjust the position of a fitting or an object under load. The bearings are permanently lubricated and sealed to keep out debris. They have excellent resistance to salt water and chemicals.