About Pressure-Relief Valves

More

About On/Off Valves

More

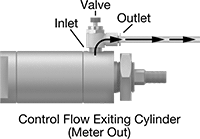

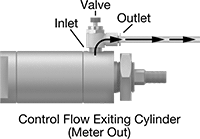

About Flow Control Valves

Also known as cylinder speed controls, flow control valves let you control the extension or retraction speed of your air cylinder. They regulate airflow as it passes from the valve's inlet to its outlet. Air flows freely in the opposite direction.

More

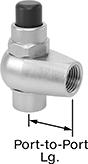

Swivel Threaded On/Off Valves

Make connections from any direction—the body of these valves swivels 360° for easy installation. Often used in testing and sampling applications, they quickly open and close with a toggle or button.

Toggle-switch valves stay open until you flip them closed. Since they don’t need to be held open, they’re often used to dispense large samples. The toggle’s position shows you if they’re open or closed.

Push-button valves open when you press the button. When released, the button springs back and automatically stops flow. They’re ideal for intermittent use and controlling flow to avoid spills.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Stem

- For Use With: Water, Oil, Air

- Seal Material: Buna-N Rubber

- Valve Type: Stem

- For Use With: Water, Oil, Air

- Seal Material: Buna-N Rubber

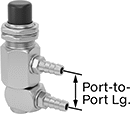

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Port-to-Port Lg. | Each | |

NPT Female × NPT Female | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8 | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 3/4" | 0000000 | 000000 |

NPT Male × NPT Female | ||||||||

| 1/8 | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 3/4" | 0000000 | 00000 |

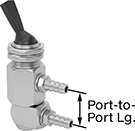

Swivel On/Off Valves with Barbed Fittings

For easy installation from any direction, the body on these valves swivels 360°. They have barbs to securely grip tubing. Often used in testing and sampling applications, they quickly open and close with a toggle or button.

Toggle-switch valves stay open until you flip them closed. Since they don’t need to be held open, they’re often used to dispense large samples. The toggle’s position shows you if they’re open or closed.

Push-button valves open when you press the button. When released, the button springs back and automatically stops flow. They’re ideal for intermittent use and controlling flow to avoid spills.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Stem

- For Use With: Air, Oil, Water

- Seal Material: Buna-N Rubber

| Thread Size | For Tube ID | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Return Actuation | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × Barbed | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Manual | 9/16" | 15/32" | 0000000 | 000000 |

UNF Male × Barbed | |||||||||

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Manual | 9/16" | 15/32" | 0000000 | 00000 |

Barbed × Barbed | |||||||||

| __ | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Manual | 9/16" | 15/32" | 0000000 | 00000 |

- Valve Type: Stem

- For Use With: Air, Oil, Water

- Seal Material: Buna-N Rubber

| Thread Size | For Tube ID | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × Barbed | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 9/16" | 15/32" | 0000000 | 000000 |

UNF Male × Barbed | ||||||||||

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 9/16" | 15/32" | 0000000 | 00000 |

Barbed × Barbed | ||||||||||

| __ | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 9/16" | 15/32" | 0000000 | 00000 |

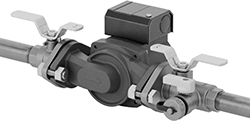

Single-Flange On/Off Valves

Bolt these valves to pipe and pump flanges to start and stop flow before pump maintenance without draining your system. They attach to industry-standard two-bolt flanges on circulation pumps from manufacturers such as Bell and Gossett, Taco, Grundfos, and Armstrong. All are full port, so they do not restrict flow.

Valves with T-handles resist accidental movement when bumped or snagged. Valves with 5/8" lg. x 1/2" wd. bolt holes fit both standard and high-velocity pumps.

- Valve Type: Ball

- For Use With: Water

- Seal Material: PTFE Plastic

Valves with rotating flange swivel 360° for easy alignment with your pipe or pump flange during installation.

Valves | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flange | Bolts | Gaskets | ||||||||||||

| Pipe Size | Ht. | Wd. | No. of Holes | Hole Lg. | Hole Wd. | Hole Ctr.-to-Ctr. | Included | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | Each | ||

Brass Body with T-Handle | ||||||||||||||

| 3/4 | 2 13/16" | 4 1/8" | 2 | 5/8" | 1/2" | 3 1/2" | Yes | 600 psi @ 100° F | 35° to 350° | 2 3/8" | 0000000 | 000000 | 0000000 | 00000 |

| 1 | 2 13/16" | 4 1/8" | 2 | 5/8" | 1/2" | 3 1/2" | Yes | 600 psi @ 100° F | 35° to 350° | 3 1/16" | 0000000 | 00000 | 0000000 | 0000 |

ASME-Code Fast-Acting Pressure-Relief Valves for Steam

- For Use With: Steam

- Temperature Range: -60° to 400° F

These valves meet ASME Code Section I for use with steam power boilers requiring pressure relief above 15 psi. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. For remote discharge, attach a drain line to the threaded relief port. Valves have a durable bronze body for a long service life.

Swivel test levers rotate 360° around the valve for use in areas with limited clearance.

Inlet | Relief Port | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Location | Maximum Pressure, psi | Pipe Size | Location | Overall Ht. | Test Mechanism | Test Lever Type | Valve Type | Specifications Met | Choose a Set Pressure, psi | Each | |

NPT Male Inlet and NPT Female Relief Port | ||||||||||||

Bronze Body—Brass Seal | ||||||||||||

| 1/2 | Bottom | 250 | 3/4 | Side | 7 5/16" | Lever | Swivel | Pop Safety | ASME BPVC.I | 0000000 | 0000000 | |

| 3/4 | Bottom | 250 | 3/4 | Side | 7 5/16" | Lever | Swivel | Pop Safety | ASME BPVC.I | 0000000 | 000000 | |

| 1 | Bottom | 250 | 1 | Side | 7 5/8" | Lever | Swivel | Pop Safety | ASME BPVC.I | 0000000 | 000000 | |

| 1 1/2 | Bottom | 250 | 1 1/2 | Side | 9 5/8" | Lever | Swivel | Pop Safety | ASME BPVC.I | 0000000 | 000000 | |

Remote-Discharge ASME-Code Fast-Acting

Pressure-Relief Valves for Air and Inert Gas

- For Use With: Air, Inert Gas

- Specifications Met: ASME BPVC.VIII

- Temperature Range: See table

Unlike valves that release discharge directly, these have a threaded relief port to direct discharge away from your work environment. They spring fully open at the set pressure and remain fully open until the system pressure is restored below the set pressure. All meet ASME Code Section VIII for use with air and inert gas pressure vessels. Body is bronze for durability and a long service life.

Swivel test levers rotate 360° around the valve for use in areas with limited clearance.

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seal | Body | Temperature Range, °F | Test Mechanism | Test Lever Type | Overall Ht. | Valve Type | Choose a Set Pressure, psi | Each | |

| Brass | Bronze | -15° to 406° | Lever | Swivel | 7 5/16" | Pop Safety | 0000000 | 0000000 | |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seal | Body | Temperature Range, °F | Test Mechanism | Test Lever Type | Overall Ht. | Valve Type | Choose a Set Pressure, psi | Each | |

| Brass | Bronze | -15° to 406° | Lever | Swivel | 7 5/16" | Pop Safety | 0000000 | 0000000 | |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seal | Body | Temperature Range, °F | Test Mechanism | Test Lever Type | Overall Ht. | Valve Type | Choose a Set Pressure, psi | Each | |

| Brass | Bronze | -15° to 406° | Lever | Swivel | 7 5/8" | Pop Safety | 0000000 | 0000000 | |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seal | Body | Temperature Range, °F | Test Mechanism | Test Lever Type | Overall Ht. | Valve Type | Choose a Set Pressure, psi | Each | |

| Brass | Bronze | -15° to 406° | Lever | Swivel | 8 3/4" | Pop Safety | 0000000 | 0000000 | |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seal | Body | Temperature Range °F | Test Mechanism | Test Lever Type | Overall Ht. | Valve Type | Choose a Set Pressure, psi | Each | |

| Brass | Bronze | -15° to 406° | Lever | Swivel | 11" | Pop Safety | 0000000 | 0000000 | |

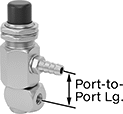

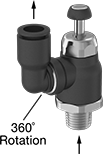

Flexible-Mount Air Flow Control Valves

A swiveling outlet port allows you to make a connection from any direction. These valves adjust the volume of air exiting an air cylinder (meter out) to control the speed of air-powered equipment. They control flow in one direction as air moves from the inlet to the outlet. Air flows freely in the opposite direction. The valve body has an elbow shape, which allows you to mount them directly to cylinder ports, eliminating additional tubing between the cylinder and valve for better control and consistency than inline valves. Insert plastic or soft metal tubing into the push-to-connect outlet ports.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

| Inlet Pipe Size | For Outlet Tube OD | Flow Coefficient (Cv) | Maximum Flow Rate @ 100 psi | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type | ISO Designation | Each | |

NPT Male Inlet × Push-to-Connect Female Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Nylon Plastic Body | ||||||||||

| 1/8 | 1/4" | 0.44 | 21.7 scfm | 145 | 35° to 155° | Dial | Exiting Cylinder | Meter Out | 0000000 | 000000 |

| 1/4 | 1/4" | 0.86 | 25.7 scfm | 145 | 35° to 155° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 1/4 | 3/8" | 3.56 | 83.2 scfm | 145 | 35° to 155° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

| 3/8 | 3/8" | 4.49 | 104.9 scfm | 145 | 35° to 155° | Dial | Exiting Cylinder | Meter Out | 0000000 | 00000 |

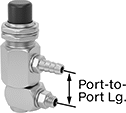

Corrosion-Resistant Single-Control Two-Direction Air Flow Control Valves

Made of PBT, these plastic valves are more corrosion resistant than valves made of aluminum or nylon. A single dial regulates the speed of airflow in two directions as it enters (meter in) and exits (meter out) equipment, and are often used to control the extension and retraction speed of an air cylinder at the same time. Insert plastic or soft metal tubing into the push-to-connect outlet ports; the outlet ports swivel 360° so you can make a connection from any direction. The elbow shape allows you to mount these valves directly to cylinder ports, eliminating additional tubing between the cylinder and valve for better control and consistency than inline valves.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve.

Flow Rate @ 73 psi | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Size | For Outlet Tube OD | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type (ISO Designation) | Each | |

PBT Plastic Body | ||||||||||

| 1/8 | 1/4" | 0.18 | 0 scfm | 7 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 000000 |

| 1/4 | 1/4" | 0.18 | 0 scfm | 7 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 00000 |

| 1/4 | 3/8" | 0.18 | 0 scfm | 7 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 00000 |

Flow Rate @ 73 psi | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Thread Size | For Outlet Tube OD | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Flow Adjustment Mechanism | Flow Control Type (ISO Designation) | Each | |

PBT Plastic Body | ||||||||||

| 10-32 | 1/8" | 0.07 | 0 scfm | 3 scfm | 145 | 25° to 140° | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 0000000 | 000000 |

Swivel On/Off Valves with Garden Hose Threads

- Valve Type: Ball

- For Use With: Water

- Temperature Range: 35° to 120° F

Keep fluids flowing—these valves twist and turn to prevent your hose from kinking. They connect to your faucet and swivel 360°, which makes it less likely your hose will kink when you move it side to side. Their lever handle is easy to turn, and lets you know if the valve is open or closed at a glance.

Zinc valves have good corrosion resistance. A plastic coating protects your hands by keeping the valve’s surface from getting too hot or cold.

Brass valves are more durable and corrosion resistant than zinc valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Add a kink absorber for additional protection to your hose. Connected between the valve and the hose, they prevent kinking from sharp up and down movements.

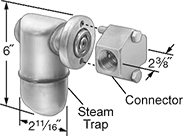

High-Flow Stainless Steel Steam Traps

Also known as inverted-bucket steam traps, these provide near-continuous discharge to accommodate high condensate levels. They are normally open to release condensate and close immediately when steam enters to prevent energy loss.

Style B attaches to a connector (sold separately) and swivels so it can be positioned both vertically and horizontally.