About Moment Loads

More

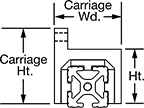

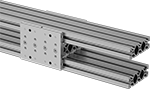

Sleeve Bearing Carriages for T-Slotted Framing

Mate with a T-slotted rail to add linear motion to your assembly. Carriages are suitable for washdown environments. Note: Carriages cannot be used upside down, vertically, or on their side.

T-slotted rails can be easily cut to length and drilled for mounting.

View additional T-slot hardware and accessories.

Hand brakes mount on the carriages to hold them in place on the rail. Carriages have mounting holes for the brakes.

End caps mount on the rails to prevent overtravel.

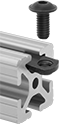

T-slot fasteners (sold separately) let you mount components to the carriages.

Carriages | Hand Brakes | T-Slot Fasteners | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd. | Dynamic Linear Load Capacity @ Speed | Static Load Cap., lbs. | Carriage Wd. | Carriage Lg. | Carriage Ht. | Carriage Color | Bearing Material | Max. Temp., °F | Each | Each | Pkg. Qty. | Pkg. | |||

For Single Rail | |||||||||||||||

| 1" | 110 lbs. @ 100 fpm | 500 | 2 15/16" | 4" | 1 1/4" | Silver | UHMW Plastic | 180° | 00000000 | 000000 | 00000000 | 000000 | 4 | 000000000 | 00000 |

| 1" | 30 lbs. @ 100 fpm | 200 | 2 15/16" | 1 7/8" | 1 1/4" | Silver | UHMW Plastic | 180° | 00000000 | 00000 | 00000000 | 00000 | 4 | 000000000 | 0000 |

| 1 1/2" | 18 lbs. @ 100 fpm | 450 | 4" | 2 13/16" | 1 7/8" | Silver | UHMW Plastic | 180° | 00000000 | 00000 | 00000000 | 00000 | 4 | 00000000 | 0000 |

| 1 1/2" | 53 lbs. @ 100 fpm | 650 | 4" | 6" | 1 7/8" | Silver | UHMW Plastic | 180° | 00000000 | 000000 | 00000000 | 00000 | 4 | 00000000 | 0000 |

| 45mm | __ | 270 | 109mm | 80mm | 54mm | __ | Acetal Plastic | 180° | 00000000 | 000000 | 00000000 | 00000 | 4 | 00000000 | 0000 |

| 45mm | __ | 540 | 109mm | 160mm | 54mm | __ | Acetal Plastic | 180° | 00000000 | 000000 | 00000000 | 00000 | 4 | 00000000 | 0000 |

For Double Rail | |||||||||||||||

| 2" | 105 lbs. @ 100 fpm | 600 | 3 15/16" | 4" | 1 1/4" | Silver | UHMW Plastic | 180° | 00000000 | 000000 | 00000000 | 00000 | 4 | 000000000 | 0000 |

| 2" | 55 lbs. @ 100 fpm | 500 | 3 15/16" | 1 7/8" | 1 1/4" | Silver | UHMW Plastic | 180° | 00000000 | 00000 | 00000000 | 00000 | 4 | 000000000 | 0000 |

| 3" | 105 lbs. @ 100 fpm | 600 | 5 1/2" | 6" | 1 7/8" | Silver | UHMW Plastic | 180° | 00000000 | 000000 | 00000000 | 00000 | 4 | 00000000 | 0000 |

| 3" | 55 lbs. @ 100 fpm | 500 | 5 1/2" | 2 13/16" | 1 7/8" | Silver | UHMW Plastic | 180° | 00000000 | 00000 | 00000000 | 00000 | 4 | 00000000 | 0000 |

Heavy Duty Sleeve Bearing Carriages for T-Slotted Framing

Threaded inserts secure the bearing to the carriage and prevent it from loosening due to frequent starts and stops. Carriages are suitable for washdown environments. Mate with a T-slotted rail to add linear motion to your assembly. Note: Carriages cannot be used upside down, vertically, or on their side.

T-slotted rails can be easily cut to length and drilled for mounting.

View additional T-slot hardware and accessories.

Hand brakes mount on the carriages to hold them in place on the rail. Drill a hole in the carriage to mount.

End caps mount on the rails to prevent overtravel.

T-slot fasteners (sold separately) let you mount components to the carriages.

| For Rail Wd. | Dynamic Linear Load Capacity @ Speed | Static Load Cap., lbs. | Carriage Wd. | Carriage Lg. | Carriage Ht. | Bearing Material | Max. Temp., °F | Each | |

For Single Rail | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 18 lbs. @ 100 fpm | 200 | 4" | 2 13/16" | 1 7/8" | UHMW Plastic | 180° | 00000000 | 0000000 |

| 1 1/2" | 33 lbs. @ 100 fpm | 450 | 4" | 6" | 1 7/8" | UHMW Plastic | 180° | 00000000 | 000000 |

For Double Rail | |||||||||

| 3" | 30 lbs. @ 100 fpm | 500 | 5 1/2" | 2 13/16" | 1 7/8" | UHMW Plastic | 180° | 00000000 | 000000 |

| 3" | 65 lbs. @ 100 fpm | 600 | 5 1/2" | 6" | 1 7/8" | UHMW Plastic | 180° | 00000000 | 000000 |

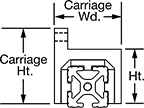

Side-Mount Sleeve Bearing Carriages for T-Slotted Framing

Fasten loads on the side of these carriages and add linear motion to a T-slot assembly. Carriages are suitable for washdown environments.

T-slotted rails can be easily cut to length and drilled for mounting.

View additional T-slot hardware and accessories.

Hand brakes mount on the carriages to hold them in place on the rail. Carriages have mounting holes for the brakes.

End caps mount on the rails to prevent overtravel.

T-slot fasteners (sold separately) let you mount components to the carriages.

| For Rail Wd. | Dynamic Linear Load Capacity @ Speed | Static Load Cap., lbs. | Carriage Wd. | Carriage Lg. | Carriage Ht. | Ht. | Bearing Material | Max. Temp., °F | Each | |

Carriage for Single Rail | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1" | 23 lbs. @ 100 fpm | 150 | 1 5/8" | 1 7/8" | 2" | 1 5/16" | UHMW Plastic | 180° | 00000000 | 000000 |

| 1" | 41 lbs. @ 100 fpm | 350 | 1 5/8" | 4" | 2" | 1 5/16" | UHMW Plastic | 180° | 00000000 | 00000 |

| 1 1/2" | 16 lbs. @ 100 fpm | 300 | 2 1/2" | 2 13/16" | 2 3/4" | 2" | UHMW Plastic | 180° | 00000000 | 00000 |

| 1 1/2" | 35 lbs. @ 100 fpm | 450 | 2 1/2" | 6" | 2 3/4" | 2" | UHMW Plastic | 180° | 00000000 | 000000 |

Heavy Duty Side-Mount Sleeve Bearing Carriages for T-Slotted Framing

Threaded inserts secure the bearing to the carriage and prevent it from loosening due to frequent starts and stops. Fasten loads on the side of the carriage and add linear motion to a T-slot assembly. Carriages are suitable for washdown environments.

T-slotted rails can be easily cut to length and drilled for mounting.

View additional T-slot hardware and accessories.

Hand brakes mount on the carriages to hold them in place on the rail. Drill a hole in the carriage to mount.

End caps mount on the rails to prevent overtravel.

T-slot fasteners (sold separately) let you mount components to the carriages.

| For Rail Wd. | Dynamic Linear Load Capacity @ Speed | Static Load Cap., lbs. | Carriage Wd. | Carriage Lg. | Carriage Ht. | Ht. | Bearing Material | Max. Temp., °F | Each | |

For Single Rail | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 18 lbs. @ 100 fpm | 300 | 2 1/2" | 2 13/16" | 2 3/4" | 2" | UHMW Plastic | 180° | 00000000 | 0000000 |

| 1 1/2" | 36 lbs. @ 100 fpm | 450 | 2 1/2" | 6" | 2 3/4" | 2" | UHMW Plastic | 180° | 00000000 | 000000 |

T-Slotted Framing Fasteners

Screw and nut sets or nuts secure brackets and other accessories to rails.

End-feed fasteners slide into the end of the rail to attach components. They form stronger connections than drop-in fasteners because more surface area touches the rail.

Center Hole

and Button Head

Offset Hole and

Flanged Button Head

Button head screws are more compact, so they're better for tight spaces than other screws for T-slotted framing.

Flanged button head screws have a wider head than standard button head fasteners, so you don’t need a washer for wide mounting holes.

Offset nuts have a mounting hole close to one end, so you can install them next to corners and rail ends.

For Rail Ht. | Mounting | Screw | Nut | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Hole Location | Fastener Thread Size | Fastener Thread Lg. | Color | Material | Color | Material | Pkg. Qty. | Pkg. | |

Single Nut with Button Head | ||||||||||||

| 1", 25mm | 2", 50mm | 3" | Center | 1/4"-20 | 1/2" | Black | Zinc-Plated Steel | Black | Zinc-Plated Steel | 4 | 000000000 | 00000 |

Single Nut with Flanged Button Head | ||||||||||||

| 1 1/2" | 3" | 4 1/2" | Offset | 5/16"-18 | 11/16" | Black | Zinc-Plated Steel | Black | Zinc-Plated Steel | 4 | 00000000 | 0000 |

| 45mm | 90mm | __ | Offset | M8 | 16mm | Black | Zinc-Plated Steel | Black | Zinc-Plated Steel | 4 | 00000000 | 0000 |

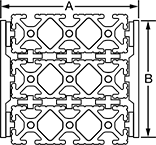

T-Slotted Framing Linear Bearings and Track Rollers

Mount components to these load-rated bearings and track rollers to add linear motion along T-slotted rails.

Bearings move more accurately than other T-slotted framing linear motion components, such as track rollers, and are often used in automated systems and other applications requiring repetitive motion. They’re lined with slippery, durable plastic and have no moving parts. These bearings withstand exposure to dirt, water, impact, and vibration. To adjust how they fit on your rail, slide one of the included shims between the bearing pad and bearing housing.

Standard sleeve bearings let you mount loads in multiple ways: using threaded holes on the panel and on the end of the mounting rail. The hole on the mounting rail end is often used to add bumpers.

Bearing pads replace worn pads.

Replacement carriage panels and mounting rails let you create custom standard sleeve bearings with different shapes and profiles.

Linear Bearings | Replacement Carriage Panel Bearing Pads | Replacement Mounting Rail Bearing Pads | Replacement Carriage Panels | Replacement Mounting Rails | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Ht. | Dynamic Load Capacity | Static Load Capacity, lbs. | Lg. | (A) | (B) | Includes | Each | Each | Each | Each | Each | |||||

Heavy Duty Strength | ||||||||||||||||

Silver Anodized Aluminum | ||||||||||||||||

| 4 1/2" | 41 lbs. @ 100 fpm | 800 | 2 13/16" | 5 1/2" | 4 3/4" | Two Carriage Panels, One Mounting Rail, Four Carriage Panel Bearing Pads, Six Mounting Rail Bearing Pads, 40 Shims | 00000000 | 0000000 | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 |

| 4 1/2" | 110 lbs. @ 100 fpm | 1,000 | 6" | 5 1/2" | 4 3/4" | Two Carriage Panels, One Mounting Rail, Eight Carriage Panel Bearing Pads, 12 Mounting Rail Bearing Pads, 80 Shims | 00000000 | 000000 | 000000000 | 0000 | 000000000 | 0000 | 00000000 | 00000 | 00000000 | 00000 |

Hand brakes hold sleeve bearing carriages in place on the rail. Single arm brakes have an adjustable grip. If space is tight, you can ratchet the grip out of the way without releasing the brake.

For Rail Ht. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Single | Double | Triple | Lg. | Wd. | Dia. | Projection | Material | Color | Each | |

Single Arm Grip Style | ||||||||||

| 1 1/2" | 3" | 4 1/2" | 3 1/2" | 7/8" | __ | 2 1/4" | Zinc | Silver | 00000000 | 000000 |

| 1 1/2" | 3" | 4 1/2" | 3 1/2" | 7/8" | __ | 2 1/4" | Zinc | Yellow | 00000000 | 00000 |

Two Arm Grip Style | ||||||||||

| 1 1/2" | 3" | 4 1/2" | 2 1/2" | 3/4" | __ | 1 1/8" | Plastic | Black | 00000000 | 0000 |

Eight Arm Grip Style | ||||||||||

| 1 1/2" | 3" | 4 1/2" | __ | __ | 1 3/8" | 7/8" | Plastic | Black | 00000000 | 0000 |

For Rail Ht. | Slot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Single | Double | Triple | Lg. | Wd. | Thickness | Lg. | Wd. | Includes | Material | Color | Each | |

| 1 | 3", 80mm | 4 1/2" | 2 13/16" | 1 1/4" | 0.005" | 2 3/16" | 1/4" | 20 Shims | Polyethylene Plastic | White | 00000000 | 00000 |