Filter by

Material

System of Measurement

Thickness

Slot Width

Thread Size

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Mounting Hole Center-to-Center

REACH

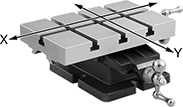

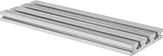

T-Slot Fixture Plates

Inch

|  |

T-Slots | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | No. of | Wd. | Ctr.-to-Ctr. | Mounting Slot Ht. | Parallel Tolerance | Material | Each | ||

| 13" | 9" | 2" | 3 | 11/16" | 2 1/2" | 5/8" | 0.0005" | Iron | 0000000 | 000000000 | |

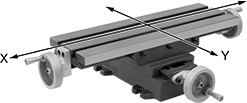

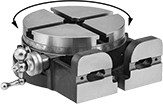

Precision-Adjust Cross-Slide Milling Tables

Table | Base | Max. Travel | X-Axis T-Slots | Y-Axis T-Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Lg. | Wd. | X-Axis | Y-Axis | X- and Y-Axis Adjustment Dial Graduations | Keyway Size | Overall Ht. | No. of | Wd. | Ctr.-to-Ctr. | No. of | Wd. | Ctr.-to-Ctr. | Flatness Tolerance | Material | Mounting Fasteners Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard-Table 50 lb. Load Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 6" | 6 3/8" | 7 5/8" | 6" | 4" | 0.001" | 5/8" | 4 3/8" | 1 | 7/16" | — | 3 | 7/16" | 2 1/2" | 0.001" | Iron | No | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard-Table 150 lb. Load Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 5/8" | 6" | 7 1/8" | 12" | 12" | 8" | 0.001" | — | 5 1/4" | 2 | 1/2" | 2 3/8" | — | — | — | 0.002" | Iron | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tilting-Table 50 lb. Load Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 6" | 5" | 9" | 8" | 4" | 0.001" | 5/8" | 4 5/8" | 1 | 7/16" | — | 3 | 7/16" | 3" | 0.001" | Iron | No | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

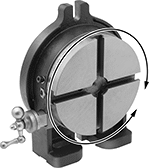

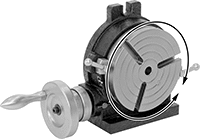

Precision-Adjust Rotary Tables

Rotary Tables | Tailstocks | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Load Cap., lb. | Base | T-Slots | Rotation Graduations | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table Dia. | Horizontal | Vertical | Gear Ratio | Lg. | Wd. | Overall Ht. | No. of | Wd. | Ctr. Bore Type | Ctr. Bore Dia. | Machine Taper No. | Adjustment Dial | Table | Flatness Tolerance | Material | Mounting Fasteners Included | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 160 | 80 | 40:1 | 12" | 9 1/2" | 3 7/8" | 2 | 5/8" | Straight | 1 5/8" | — | 1/20° | 1° | 0.002" | Iron | No | 000000 | 000000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 200 | 100 | 40:1 | 12" | 9 1/2" | 3 7/8" | 2 | 5/8" | Straight | 1 5/8" | — | 1/20° | 1° | 0.002" | Iron | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 265 | 130 | 90:1 | 15 5/16" | 13" | 5" | 6 | 5/8" | Morse Taper | — | Morse 3 | 1/10° | 1° | 0.0006" | Iron | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 310 | 130 | 90:1 | 20" | 17" | 5 1/8" | 6 | 5/8" | Morse Taper | — | Morse 4 | 1/10° | 1° | 0.0006" | Iron | No | 000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

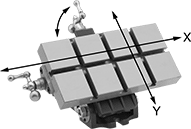

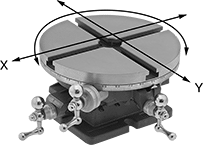

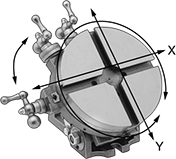

Precision-Adjust Cross-Slide Rotary Tables

Load Cap., lb. | Base | Max. Travel | T-Slots | Rotation Graduations | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Table Dia. | Horizontal | Vertical | Gear Ratio | Lg. | Wd. | X-Axis | Y-Axis | X- and Y-Axis Adjustment Dial Graduations | Overall Ht. | No. of | Wd. | Ctr. Bore Type | Ctr. Bore Dia. | Adjustment Dial | Table | Flatness Tolerance | Material | Mounting Fasteners Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 160 | 80 | 40:1 | 6 1/4" | 7 1/2" | 4" | 4" | 0.001" | 5 1/2" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 200 | 100 | 40:1 | 6 1/4" | 7 1/2" | 4" | 4" | 0.001" | 5 3/8" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tilting Table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 160 | 80 | 40:1 | 5" | 9" | 4" | 4" | 0.001" | 5" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 200 | 100 | 40:1 | 5" | 9" | 4" | 4" | 0.001" | 5 3/4" | 2 | 5/8" | Straight | 1 5/8" | 1/20° | 1° | 0.001" | Iron | No | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

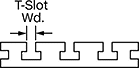

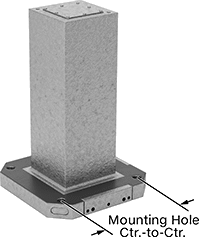

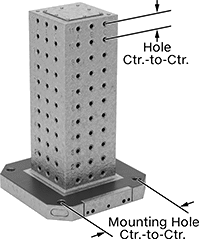

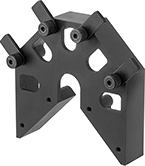

Fixture Columns

Blank

|  |  |

Square | Rectangle | Cross |

Column | Base | Mounting Holes | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Overall Ht. | Lg. | Wd. | Thk. | No. of | Style | Ctr.-to-Ctr. | For Mounting Screw Size | Wt., lb. | Squareness | Parallel | Flatness | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 8" | 22" | 24" | 15 3/4" | 15 3/4" | 2" | 4 | Slotted | 6" | 5/8" | 405 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 10" | 26" | 28" | 19 3/4" | 19 3/4" | 2" | 4 | Slotted | 8" | 5/8" | 635 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 3/4" | 4" | 26" | 28" | 15 3/4" | 15 3/4" | 2" | 6 | Slotted | 6" | 5/8" | 555 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 3/4" | 4" | 26" | 28" | 19 3/4" | 19 3/4" | 2" | 6 | Slotted | 8" | 5/8" | 735 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cross | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 10" | 26 1/2" | 28" | 15 3/4" | 15 3/4" | 1 1/2" | 8 | Slotted | 6" | 5/8" | 555 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

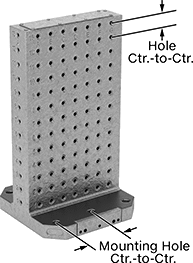

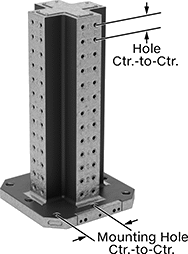

Grid

|  |  |

Square | Rectangle | Cross |

Columns | Aluminum Chip Plugs | Replacement Plastic Chip Plugs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Column | Base | Holes | Mounting Holes | Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lg. | Wd. | Ht. | Overall Ht. | Lg. | Wd. | Thk. | No. of | Thread Size | Ctr.-to-Ctr. | No. of | Style | Ctr.-to-Ctr. | For Mounting Screw Size | Wt., lb. | Squareness | Parallel | Flatness | Material | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 8" | 22" | 24" | 15 3/4" | 15 3/4" | 2" | 132 | 1/2"-13 | 2" | 4 | Slotted | 6" | 5/8" | 405 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 000000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 10" | 26" | 28" | 19 3/4" | 19 3/4" | 2" | 208 | 1/2"-13 | 2" | 4 | Slotted | 8" | 5/8" | 635 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 3/4" | 4" | 26" | 28" | 15 3/4" | 15 3/4" | 2" | 208 | 1/2"-13 | 2" | 6 | Slotted | 6" | 5/8" | 555 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 3/4" | 4" | 26" | 28" | 19 3/4" | 19 3/4" | 2" | 260 | 1/2"-13 | 2" | 6 | Slotted | 8" | 5/8" | 735 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cross | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 10" | 26 1/2" | 28" | 15 3/4" | 15 3/4" | 1 1/2" | 156 | 1/2"-13 | 2" | 8 | Slotted | 6" | 5/8" | 555 | 0.0008" | 0.0005" | 0.0005" | Cast Iron | 00000000 | 00000000 | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

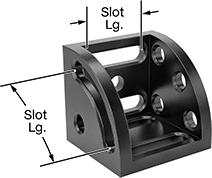

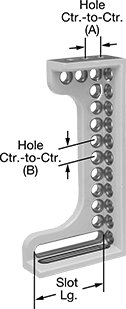

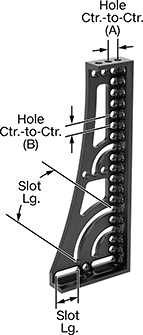

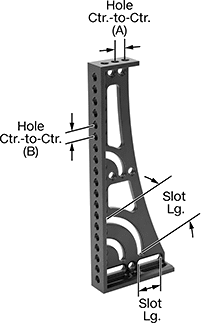

Fixture Squares

|  |

Style B | Style E |

|  |

Style F (Left Orientation) | Style F (Right Orientation) |

Slots | Holes | Tolerance | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Lg. | Wd. | Ht. | Plate Thk. | Orientation | No. of | Shape | Lg. | Wd. | No. of | Dia. | Ctr.-to-Ctr. (A) | Ctr.-to-Ctr. (B) | Wt., lb. | Squareness per 4" | Parallel | Material | Each | |||

| B | 3 3/4" | 4" | 3 3/4" | 1/2" | — | 4 1 | Straight Curved | 2" 2 13/16" | 5/8" 5/8" | 6 | 5/8" | 2" | — | 5 | Not Rated | Not Rated | Iron | 00000000 | 0000000 | ||

| E | 6" | 2" | 12" | 1/2" | — | 2 | Straight | 4" | 5/8" | 26 | 5/8" | 1" | 1" | 7 | 0.002" | 0.006" | Iron | 0000000 | 000000 | ||

| F | 8" | 2" | 20" | 1/2" | Left-Hand Side | 4 2 1 | Straight Curved Curved | 2" 2 13/16" 5 5/8" | 5/8" 5/8" 5/8" | 43 | 5/8" | 1" | 1" | 15 | Not Rated | Not Rated | Iron | 00000000 | 000000 | ||

| F | 8" | 2" | 20" | 1/2" | Right-Hand Side | 4 2 1 | Straight Curved Curved | 2" 2 13/16" 5 5/8" | 5/8" 5/8" 5/8" | 43 | 5/8" | 1" | 1" | 15 | Not Rated | Not Rated | Iron | 00000000 | 000000 | ||

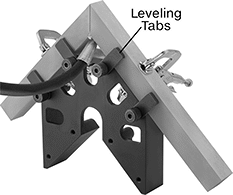

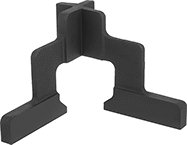

Welding Fixture Squares

|

|  |  |

2 Axes With Leveling Tabs | 2 Axes with Joint Access Cutouts and Leveling Tabs | 3 Axes |

Overall | Cast Iron | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Holding Angle | Lg. | Wd. | Ht. | Flange Thk. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Axes with Leveling Tabs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45°, 90° | 4" | 4" | 1 1/2" | 1/4" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45°, 90° | 6" | 6" | 1 1/2" | 1/4" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45°, 90° | 12" | 12" | 3" | 1/4" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Axes with Joint Access Cutouts and Leveling Tabs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45°, 90° | 4" | 4" | 1 1/2" | 1/4" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45°, 90° | 6" | 6" | 1 1/2" | 1/4" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45°, 90° | 12" | 12" | 3" | 3/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Axes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 10 1/2" | 10 1/2" | 8" | 1" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||