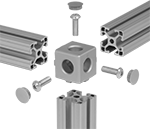

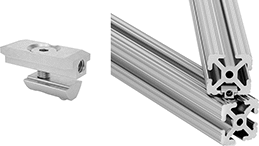

T-Slotted Framing Structural Brackets

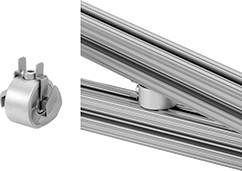

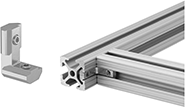

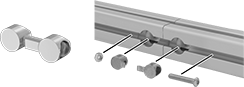

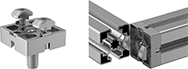

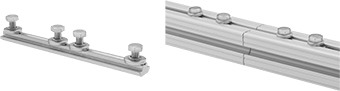

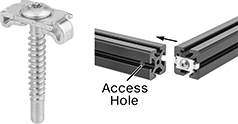

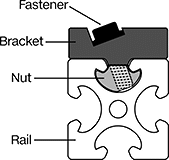

Connect T-slotted rails and reinforce joints for structural stability. Fasteners are included.

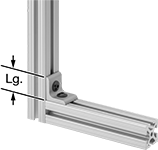

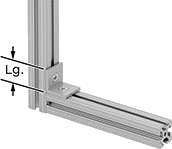

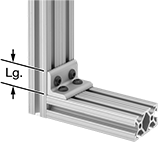

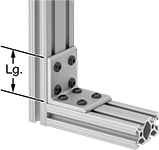

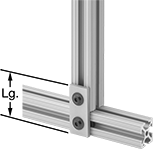

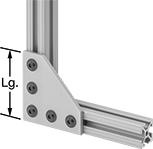

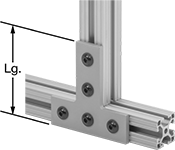

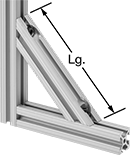

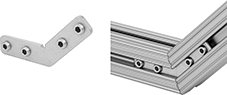

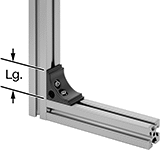

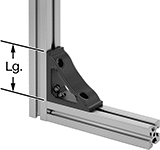

Corner brackets are also known as angle brackets.

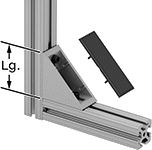

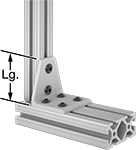

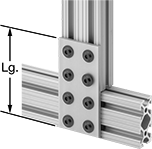

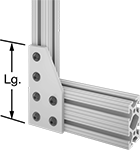

Extended brackets have more connection points for stronger connections than standard-length brackets.

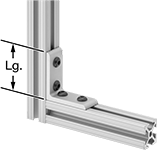

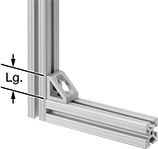

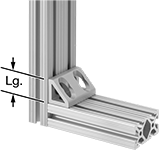

Slotted corner brackets have elongated mounting holes for increased adjustability.

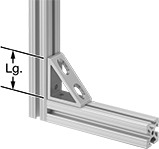

Countersunk brackets have a more finished appearance than brackets with straight mounting holes because their fasteners sit flush with the brackets. The screw heads won’t get in the way of your other components.

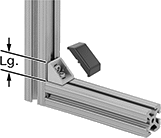

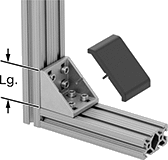

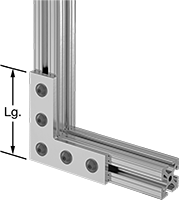

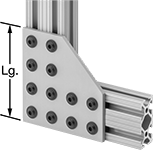

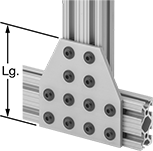

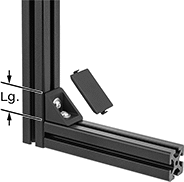

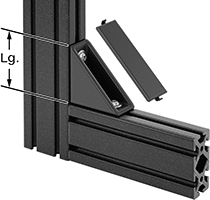

Gusset brackets are reinforced to limit sway for more structural stability than standard corner brackets. Open gusset brackets give you easy access to the fasteners, which is useful if your application requires frequent adjustments. Closed gusset brackets include a cover for a finished appearance and better dust protection than open gusset brackets. Quick-install closed gusset brackets come with mounting fasteners attached to make installation easy. To install, drop the attached nuts into the T-slot, then tighten the screws a quarter turn. They come with a cover for a finished appearance.

| For Rail Ht. | Lg. | Rail Machining | Mounting Fasteners Included | Material | Each | |

Silver | ||||||

|---|---|---|---|---|---|---|

Corner | ||||||

| 40mm | 1 5/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Extended Corner | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Slotted Corner | ||||||

| 40mm | 1 9/16" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 0000 |

Extended Slotted Corner | ||||||

| 40mm | 1 9/16" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 00000 |

Countersunk Corner | ||||||

| 1 1/2", 40mm | 1 37/64" | Not Required | Yes | Powder-Coated Steel | 0000000 | 00000 |

Open Gusset | ||||||

| 40mm | 1 37/64" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 0000 |

Extended Open Gusset | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Anodized 6063 Aluminum | 0000000 | 00000 |

Closed Gusset | ||||||

| 1 1/2", 40mm | 1 27/64" | Not Required | Yes | 6063 Aluminum | 0000000 | 0000 |

Extended Closed Gusset | ||||||

| 1 1/2", 40mm | 3" | Not Required | Yes | Powder-Coated Zinc | 0000000 | 00000 |

Quick-Install Closed Gusset | ||||||

| 1 1/2", 40mm | 1 37/64" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Extended Quick-Install Closed Gusset | ||||||

| 1 1/2", 40mm | 3 5/32" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Black | ||||||

Corner | ||||||

| 40mm | 1 5/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 0000 |

Extended Corner | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Slotted Corner | ||||||

| 40mm | 1 37/64" | Not Required | Yes | Anodized 6105 Aluminum | 0000000 | 00000 |

Countersunk Corner | ||||||

| 1 1/2", 40mm | 1 37/64" | Not Required | Yes | Powder-Coated Steel | 0000000 | 00000 |

Open Gusset | ||||||

| 40mm | 1 37/64" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 0000 |

Extended Open Gusset | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Closed Gusset | ||||||

| 1 1/2", 40mm | 1 27/64" | Not Required | Yes | Powder-Coated Aluminum | 0000000 | 00000 |

Corner brackets are also known as angle brackets.

Extended brackets have more connection points for stronger connections than standard-length brackets.

Gusset brackets are reinforced to limit sway for more structural stability than standard corner brackets. Open gusset brackets give you easy access to the fasteners, which is useful if your application requires frequent adjustments. Closed gusset brackets include a cover for a finished appearance and better dust protection than open gusset brackets.

| For Rail Ht. | Lg. | Rail Machining | Mounting Fasteners Included | Material | Each | |

Silver | ||||||

|---|---|---|---|---|---|---|

Corner | ||||||

| 40mm | 3/4" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 000000 |

Extended Corner | ||||||

| 40mm | 1 5/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Open Gusset | ||||||

| 40mm | 1 37/64" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Extended Closed Gusset | ||||||

| 40mm | 1 27/64" | Not Required | Yes | 6063 Aluminum | 00000000 | 00000 |

Black | ||||||

Corner | ||||||

| 40mm | 3/4" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Extended Corner | ||||||

| 40mm | 1 5/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 0000000 | 00000 |

Open Gusset | ||||||

| 40mm | 1 37/64" | Not Required | Yes | Anodized 6063 Aluminum | 0000000 | 00000 |

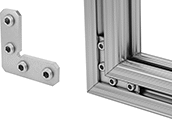

Corner brackets are also known as angle brackets.

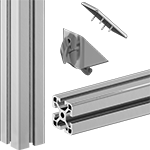

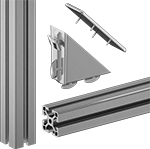

Outside corner and three-way outside corner brackets connect the ends of rails for a finished look at your corner. To install, tap the existing hole in the end of each rail and screw the bracket in.

| For Rail Ht. | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Each | |

Outside Corner for Four Slot Single Rails | ||||||||

|---|---|---|---|---|---|---|---|---|

| 40mm | 1 37/64" | Black | Powder-Coated Aluminum | M8 | Required | Yes | 0000000 | 000000 |

| 40mm | 1 5/8" | Silver | Lacquer-Coated 6063 Aluminum | M8 | Required | Yes | 00000000 | 00000 |

Three-Way Outside Corner for Four Slot Single Rails | ||||||||

| 40mm | 1 37/64" | Black | Powder-Coated Aluminum | M8 | Required | Yes | 0000000 | 00000 |

| 40mm | 1 5/8" | Silver | Lacquer-Coated 6063 Aluminum | M8 | Required | Yes | 00000000 | 00000 |

Corner brackets are also known as angle brackets.

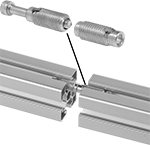

Adapter brackets connect rails with different rail profiles.

| For Rail Ht. | Lg. | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

Center Adapter Bracket for Double/Quad to Single Rails | |||||||

|---|---|---|---|---|---|---|---|

| 40mm | 3 5/32" | Silver | Anodized 6105 Aluminum | Not Required | Yes | 00000000 | 000000 |

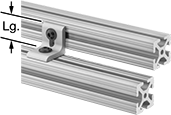

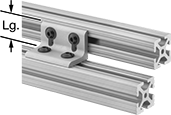

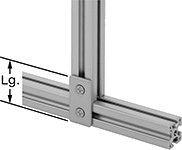

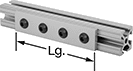

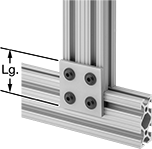

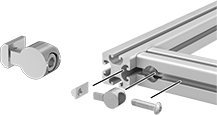

Surface brackets create strong connection points because they secure to the surface of rails.

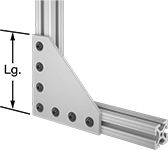

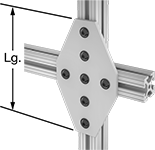

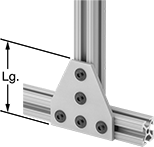

Straight brackets are simple brackets that can be used to make 90°, end-to-end, and parallel connections.

Countersunk straight brackets have a more finished appearance than brackets with straight mounting holes because their fasteners sit flush with the brackets. The screw heads won’t get in the way of your other components.

Extended brackets have more connection points for stronger connections than standard-length brackets.

15° angle brackets connect rails at a slight angle, so they are often used to create sloped shelves.

90° angle brackets make a corner or create another 90° connection along your rail.

Flush tee and flush 90° angle brackets create a finished appearance. However, they are not as strong as standard tee or 90° angle brackets.

Quick-install brackets come with mounting fasteners attached to make installation easy. To install, drop the attached nuts into the T-slot, then tighten the screws a quarter turn.

| For Rail Ht. | Lg. | Rail Machining | Mounting Fasteners Included | Material | Each | |

Silver | ||||||

|---|---|---|---|---|---|---|

Straight | ||||||

| 1 1/2", 40mm | 3" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

| 40mm | 3" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 0000 |

Countersunk Straight | ||||||

| 1 1/2", 40mm | 3 5/32" | Not Required | Yes | Powder-Coated Steel | 0000000 | 00000 |

Extended Straight | ||||||

| 40mm | 6 1/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

15° Angle | ||||||

| 40mm | 3 11/16" | Not Required | Yes | Anodized 6105 Aluminum | 0000000 | 00000 |

30° Angle | ||||||

| 40mm | 3 5/8" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

45° Angle | ||||||

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

60° Angle | ||||||

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

90° Angle | ||||||

| 40mm | 4 5/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Extended 90° Angle | ||||||

| 40mm | 6 5/16" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 00000 |

Cross | ||||||

| 40mm | 7 7/8" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 00000 |

Tee | ||||||

| 1 1/2", 40mm | 4 1/2" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

| 40mm | 4 5/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Flush Tee | ||||||

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 00000 |

Flush 90° Angle | ||||||

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 00000 |

Quick-Install 90° Angle | ||||||

| 40mm | 4 11/16" | Not Required | Yes | Lacquer-Coated Aluminum | 0000000 | 00000 |

Quick-Install Straight | ||||||

| 40mm | 1 37/64" | Not Required | Yes | Lacquer-Coated Aluminum | 0000000 | 00000 |

Black | ||||||

Straight | ||||||

| 1 1/2", 40mm | 3" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

| 40mm | 3" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Countersunk Straight | ||||||

| 1 1/2", 40mm | 3 5/32" | Not Required | Yes | Powder-Coated Steel | 0000000 | 00000 |

Extended Straight | ||||||

| 40mm | 6 1/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

15° Angle | ||||||

| 40mm | 3 11/16" | Not Required | Yes | Anodized 6105 Aluminum | 0000000 | 00000 |

90° Angle | ||||||

| 40mm | 4 5/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Extended 90° Angle | ||||||

| 40mm | 6 5/16" | Not Required | Yes | Anodized 6105 Aluminum | 0000000 | 00000 |

Tee | ||||||

| 1 1/2", 40mm | 4 1/2" | Not Required | Yes | Anodized 6105 Aluminum | 000000000 | 00000 |

| 40mm | 4 5/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Flush Tee | ||||||

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6105 Aluminum | 0000000 | 00000 |

Flush 90° Angle | ||||||

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6105 Aluminum | 0000000 | 00000 |

Yellow | ||||||

Straight | ||||||

| 1 1/2", 40mm | 3" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 0000 |

Tee | ||||||

| 1 1/2", 40mm | 4 1/2" | Not Required | Yes | Anodized 6105 Aluminum | 00000000 | 00000 |

Surface brackets create strong connection points because they secure to the surface of rails.

Straight brackets are simple brackets that can be used to make 90°, end-to-end, and parallel connections.

Extended brackets have more connection points for stronger connections than standard-length brackets.

90° angle brackets make a corner or create another 90° connection along your rail.

| For Rail Ht. | Lg. | Rail Machining | Mounting Fasteners Included | Material | Each | |

Silver | ||||||

|---|---|---|---|---|---|---|

Straight | ||||||

| 40mm | 1 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 000000 |

Extended Straight | ||||||

| 40mm | 3" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

90° Angle | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Tee | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Black | ||||||

Straight | ||||||

| 40mm | 1 1/2" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Extended Straight | ||||||

| 40mm | 3" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

90° Angle | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Tee | ||||||

| 40mm | 3 1/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Adjustable-angle brackets let you mount one rail to another at many different angles.

Concealed adjustable-angle brackets connect rails flush to each other at any angle.

Offset adjustable-angle brackets use a bracket placed between the rails to mount one rail next to another at any angle, including parallel to the connected rail.

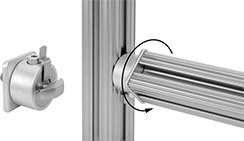

Rotating end-mount adjustable-angle brackets create a 90° connection between two rails that lets one rail rotate around its connection point.

For Rail Ht. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Each | |

Concealed | ||||||||||

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | 1 1/2" | Silver | Zinc-Plated Steel | __ | Not Required | Yes | 0000000 | 000000 |

Offset | ||||||||||

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | 25/32" | Silver | Zinc-Plated Aluminum | __ | Not Required | Yes | 0000000 | 00000 |

Rotating End Mount | ||||||||||

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | 25/32" | Silver | Zinc-Plated Aluminum | M8 | Required | Yes | 0000000 | 00000 |

Adjustable-angle brackets let you mount one rail to another at many different angles.

Reducer brackets connect rails of different rail heights.

| For Rail Ht., mm | Lg. | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 40, 45 | 1 1/2" | Silver | Zinc-Plated Steel | Not Required | Yes | 0000000 | 000000 |

Adapter brackets connect rails with different rail profiles.

Surface brackets create strong connection points because they secure to the surface of rails.

| For Rail Ht. | Lg. | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

90° Angle Adapter Bracket for Double/Quad to Single Rails | |||||||

|---|---|---|---|---|---|---|---|

| 40mm | 6 5/16" | Silver | Anodized 6105 Aluminum | Not Required | Yes | 00000000 | 000000 |

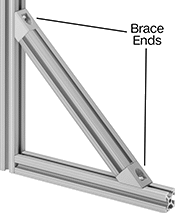

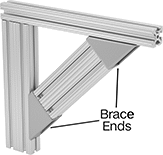

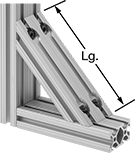

With ends mitered at a 45° angle, attach diagonal braces inside corners to create sturdier 90° connections than other brackets to reinforce your structures.

Silver | Black | |||||||

|---|---|---|---|---|---|---|---|---|

| For Rail Ht. | Lg. | Material | Rail Machining | Mounting Fasteners Included | Each | Each | ||

| 40mm | 6" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 000000 | 0000000 | 000000 |

| 40mm | 12" | Anodized 6560 Aluminum | Not Required | Yes | 0000000 | 00000 | 0000000 | 00000 |

| 40mm | 18" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 00000 | 000000 | 00 |

| 40mm | 24" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 00000 | 000000 | 00 |

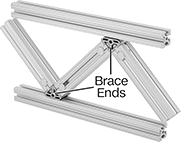

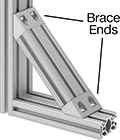

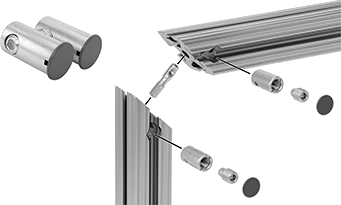

Use diagonal brace ends to make a brace of any length—a connecting rail (sold separately) between the brace ends is required. To install, use a tap (sold separately) to create a threaded hole, then fasten the brace end to a connecting rail using the included hardware.

| For Rail Ht. | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Pkg. Qty. | Pkg. | |

| 40mm | 2 1/16" | Silver | Zinc | M8 | Required | Yes | 2 | 00000000 | 000000 |

Mount two brace rails at a single point on your primary rail.

Use diagonal brace ends to make a brace of any length—a connecting rail (sold separately) between the brace ends is required. To install, use a tap (sold separately) to create a threaded hole, then fasten the brace end to a connecting rail using the included hardware.

| For Rail Ht. | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 1 37/64" | Silver | 6063 Aluminum | M8 | Required | Yes | 0000000 | 000000 |

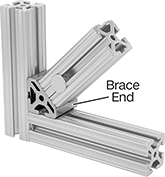

Mount a brace rail in the corner of a 90° rail assembly to reinforce the corner connection as well as the overall structure.

Use diagonal brace ends to make a brace of any length—a connecting rail (sold separately) between the brace ends is required. To install, use a tap (sold separately) to create a threaded hole, then fasten the brace end to a connecting rail using the included hardware.

| For Rail Ht. | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 1 37/64" | Silver | 6063 Aluminum | M8 | Required | Yes | 0000000 | 000000 |

Diagonal brace ends for single and double rails allow connections from a double rail to either a single rail or a double rail. A connecting rail (sold separately) between the brace ends is required. To install, use a tap (sold separately) to create a threaded hole, then fasten the brace end to a connecting rail using the included hardware.

For Rail Ht. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Single | Double | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 3", 80mm | 3 5/32" | Silver | Powder-Coated Aluminum | M8 | Required | Yes | 0000000 | 000000 |

With ends mitered at a 45° angle, attach diagonal braces inside corners to create sturdier 90° connections than other brackets to reinforce your structures.

Silver | ||||||

|---|---|---|---|---|---|---|

| For Rail Ht. | Lg. | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 40mm | 6" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 000000 |

| 40mm | 12" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 00000 |

| 40mm | 18" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 00000 |

| 40mm | 24" | Anodized 6560 Aluminum | Not Required | Yes | 00000000 | 00000 |

Use diagonal brace ends to make a brace of any length—a connecting rail (sold separately) between the brace ends is required. To install, use a tap (sold separately) to create a threaded hole, then fasten the brace end to a connecting rail using the included hardware.

| For Rail Ht. | Lg. | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Pkg. Qty. | Pkg. | |

| 40mm | 15/16" | Silver | 6063 Aluminum | M5 | Required | Yes | 2 | 00000000 | 000000 |

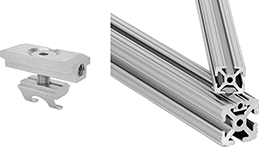

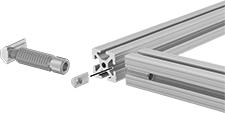

Concealed brackets mount internally and stay out of sight once installed.

Straight concealed brackets slide into T-slots.

For Rail Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 3", 80mm | 4 1/2" | Silver | Zinc-Plated Steel | Not Required | Yes | 00000000 | 00000 |

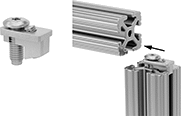

Concealed brackets mount internally and stay out of sight once installed.

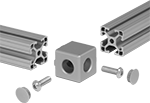

Corner concealed brackets slide into the T-slots of your two intersecting rails, leaving the outside surface slots open for mounting other components.

For Rail Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 30mm, 40mm | 3", 60mm, 80mm | 4 1/2" | Silver | Zinc | Not Required | Yes | 00000000 | 00000 |

Concealed brackets mount internally and stay out of sight once installed.

Extended corner concealed brackets have more connection points for stronger connections than standard-length brackets. They slide into the T-slots of your two intersecting rails, leaving the outside surface slots open for mounting other components. Tighten the included set screws to hold them in place.

For Rail Ht. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Lg. | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | 2 1/2" | Silver | Anodized 6105 Aluminum | Not Required | Yes | 00000000 | 000000 |

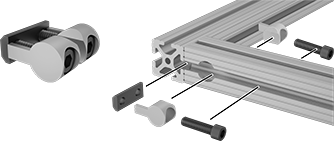

Concealed brackets mount internally and stay out of sight once installed.

Tee concealed brackets thread directly into a T-slot and use the included fastener to secure.

Concealed brackets mount internally and stay out of sight once installed.

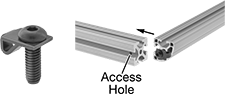

Anchor concealed brackets allow positioning anywhere along the mating rail’s T-slot. Drill an installation hole in the face of one rail to install. Since the fastener is machined into the rail profile, these brackets create stronger connections than other brackets that don’t require machining. You can also use these brackets with our rails with machined bore holes.

Concealed brackets mount internally and stay out of sight once installed.

Double anchor concealed brackets allow positioning anywhere along the mating rail’s T-slot. Drill installation holes in two faces of one rail to install. Since the fasteners are machined into the rail profile, these brackets create stronger connections than other brackets that don’t require machining.

| For Rail Ht. | Color | Material | No. of Installation Holes Required | Required Installation Hole Dia. | Rail Machining | Mounting Fasteners Included | Each | |

| 40mm | Silver | Zinc | 2 | 20mm | Required | Yes | 00000000 | 000000 |

Concealed brackets mount internally and stay out of sight once installed.

Butt anchor concealed brackets join rails end-to-end to create longer rails. Drill an installation hole in the face of each rail to install. Since the fasteners are machined into the rail profile, these brackets create stronger connections than other brackets that don’t require machining.

Concealed brackets mount internally and stay out of sight once installed.

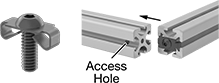

Tabbed concealed brackets require one hole to install the connector and one drilled access hole in the mating rail to secure the connection. You can also use these brackets with our machined rails with tapped or access holes. The brackets with a required tap thread size create stronger connections than other brackets that don't have tapped holes because the fasteners are machined into the rail profile. Brackets without a required tap thread size include thread-forming screws so you won't need to tap the end of your rail to install the connector. However, this connection is not as strong as the connections with a tapped hole.

| For Rail Ht. | Color | Material | Required Tap Thread Size | Required Access Hole Dia. | Rail Machining | Mounting Fasteners Included | Each | |

Tabbed Concealed Brackets | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 1/2", 40mm | Black | Zinc-Plated Steel | 5/16"-18 | 5/16" | Required | Yes | 000000000 | 00000 |

| 1 1/2", 40mm | Silver | Zinc-Plated Steel | __ | 9mm | Required | Yes | 0000000 | 0000 |

| 40mm | Silver | Zinc-Plated Steel | M8 | 7.5mm | Required | Yes | 0000000 | 0000 |

Tabbed Concealed Brackets for Radius Two Slot Rails | ||||||||

| 1 1/2", 40mm | Black | Zinc-Plated Steel | 5/16"-18 | 5/16" | Required | Yes | 00000000 | 0000 |

Concealed brackets mount internally and stay out of sight once installed.

Easy-install tabbed concealed brackets come with a self-tapping screw, so you won't need to tap the end of your rail or drill an acess hole to make 90° and corner connections. Position them anywhere along the length of your rail. Their connections are stronger than corner concealed brackets and tabbed concealed brackets but not quite as strong as anchor brackets.

For Rail Ht., mm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 40 | 80 | 120 | Silver | Zinc-Plated Steel | Not Required | Yes | 0000000 | 00000 |

Concealed brackets mount internally and stay out of sight once installed.

Plate connector concealed brackets create a structural bracket connection point on the end of one rail that can attach at a 90° angle along another rail. They have a screw on one side and a T-slot nut on the other. Tap a hole in the end of one rail and thread in the screw. Then slide the T-slot nut into the slot of the other rail. Brackets with no required tap thread size include thread-forming screws.

For Rail Ht., mm | |||||||

|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 40 | 80 | Black | Plastic | Not Required | Yes | 0000000 | 000000 |

Easy-adjust plate connector concealed brackets have fasteners that remain accessible after installation to simplify position changes. Often used to make shelf supports or cross bars to reinforce a structure, they create a structural bracket connection point on the end of one rail that can attach at a 90° angle along another rail. Install these brackets into the tapped end of a rail. Then, slide the spring-loaded ball nut into the slot on the other rail. Finally, fasten the outside bracket to the nut to connect the rails. You’ll get two brackets with all the included hardware.

For Rail Ht. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Color | Material | Required Tap Thread Size | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | Silver | Zinc-Plated Steel | M8 | Required | Yes | 0000000 | 000000 |

Concealed brackets mount internally and stay out of sight once installed.

Miter concealed brackets connect rails with 45° or 90° miters. Slide them into the T-slots and tighten them in place with the included set screws.

For Rail Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

45° Angle Alignment Style | ||||||||

| 1 1/2", 30mm, 40mm | 3", 60mm, 80mm | 4 1/2", 120mm | Silver | Zinc-Plated Steel | Not Required | Yes | 0000000 | 000000 |

90° Angle Alignment Style | ||||||||

| 1 1/2", 30mm, 40mm | 3", 60mm, 80mm | 4 1/2", 120mm | Silver | Zinc-Plated Steel | Not Required | Yes | 0000000 | 00000 |

Concealed anchors mount internally and stay out of sight once installed.

Miter butt anchors create the strongest miter connection because the fasteners are machined into the rail profiles. Use them to join rails with 60°, 90°, and 180° miters. Drill an installation hole in the face of each rail to install.

For Rail Ht. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | Color | Material | Includes | No. of Installation Holes Required | Required Installation Hole Dia. | Rail Machining | Mounting Fasteners Included | Each | |

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | Silver | Zinc-Plated Steel | Hole Covers | 2 | 14.2mm | Required | Yes | 0000000 | 000000 |

Concealed connectors mount internally and stay out of sight once installed.

Butt and extended butt connectors join rails end-to-end to extend the length of rails without machining. Slide the connectors into a T-slot and tighten the screws to install.

Extended connectors have more connection points for stronger connections than standard-length brackets.

For Rail Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Lg. | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

Extended Butt Connector | ||||||||

| 1 1/2", 40mm | 3", 80mm | 7" | Silver | Zinc-Plated Steel | Not Required | Yes | 00000000 | 000000 |

Concealed brackets mount internally and stay out of sight once installed.

Binding barrel concealed brackets thread directly into a T-slot and join rails end-to-end.

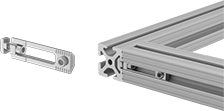

Lightweight Composite T-Slotted Framing and Fittings

Build lightweight structures, such as light duty machine guards, enclosures, and carts, with framing that is two-thirds the weight of aluminum framing. Made of 30% polypropylene and 70% wood, they’re not as strong as aluminum rails, but they’re nonconductive, easy to machine, and more corrosion resistant. Good for lab environments, they also withstand cleaning with chemicals better than aluminum. Use their continuous T-slots to attach fittings. They work with any T-slotted component for 40 mm rails that doesn’t require machining. View additional structural brackets and fasteners.

Brackets connect T-slotted composite rails for structural stability. Fasteners are included.

Corner brackets are also known as angle brackets. These brackets don’t require you to machine your rails.

Closed gusset brackets include a black plastic cover for a finished appearance.

Concealed brackets mount inside rails, so they stay out of the way and out of sight once installed.

Tabbed brackets mount inside a hole in one rail and require a drilled access hole in the mating rail to secure the connection. They come with thread-forming screws, so you don't need to tap the end of your rail.

| For Rail Ht., mm | Color | Material | Rail Machining | Required Access Hole Dia., mm | Mounting Fasteners Included | Each | |

| 40 | Silver | Zinc-Plated Steel | Required | 7 | Yes | 0000000 | 00000 |

Heavy Duty Locking-Slotted Framing and Fittings

Build structures that stand up to more vibration and movement than T-slotted framing but with the same versatility and installation ease. Instead of T-shaped slots, these rails have slots that turn up and inward to keep connections rigidly locked together. Use them to make strong and stable platforms, machine bases, and much more.

Corner brackets are self-aligning and won’t loosen or slip from vibration. They have angled mounting holes for anchoring to the inside of rails. Special angled fasteners come attached for fast installation. To limit sway for added stability, these brackets are reinforced with gussets.

Surface brackets are self-aligning and won’t loosen or slip from vibration. They have angled mounting holes for anchoring to the inside of rails. Special angled fasteners come attached for fast installation.

Use mounting brackets to secure benchtops and other components to rails, attach assemblies, or transition to other framing systems. One of their legs has an angled mounting hole for anchoring to the inside of a rail. Special angled fasteners come attached to it for fast installation.

Open gusset brackets are reinforced to limit sway, adding stability.

| For Rail Ht., mm | Lg. | Color | Material | For Mounting Orientation | Mounting Fasteners Included | Mounting Hole Dia., mm | Features | Each | |

Corner | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 40 | 1 1/2" | Black | Anodized Aluminum | Perpendicular | Yes | 8.5 | Quick-Install Angled Fasteners | 0000000 | 000000 |

Open Gusset | |||||||||

| 40 | 1" | Black | Anodized Aluminum | Parallel | Yes | 22 | Quick-Install Angled Fasteners | 0000000 | 00000 |